- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7700

-

Voltage:

-

220v/380v

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

1260*800*1880mm

-

Marketing Type:

-

Hot Product 2024

-

Customized:

-

Customized

-

Capacity:

-

0.5T/h

-

Transport Package:

-

Fumigation-Free Wooden Case

-

Material:

-

Stainless Steel 304

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

shenzhou

-

Processing Types:

-

apple, orange,ect

-

Power:

-

7700

-

Voltage:

-

220v/380v

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

1260*800*1880mm

-

Marketing Type:

-

Hot Product 2024

-

Customized:

-

Customized

-

Capacity:

-

0.5T/h

-

Transport Package:

-

Fumigation-Free Wooden Case

-

Material:

-

Stainless Steel 304

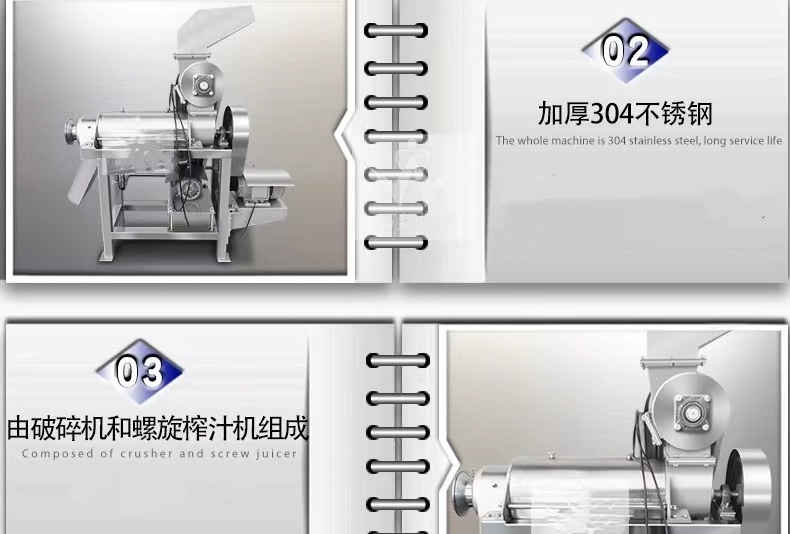

Products Description

1.Automatic water slag separation

2.High juice yield

3.High pressing force

4.Quick juice

5.Juice extraction, dehydration, filtration, and pressing

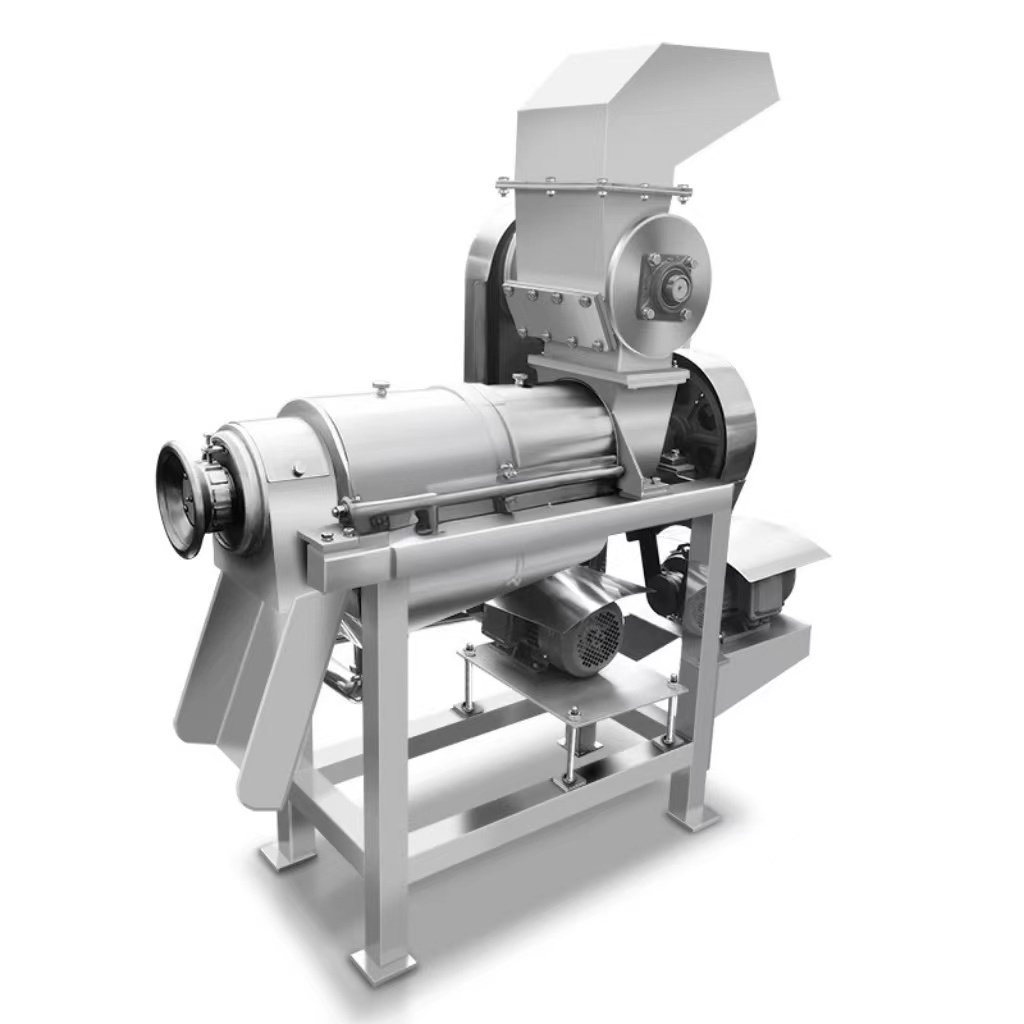

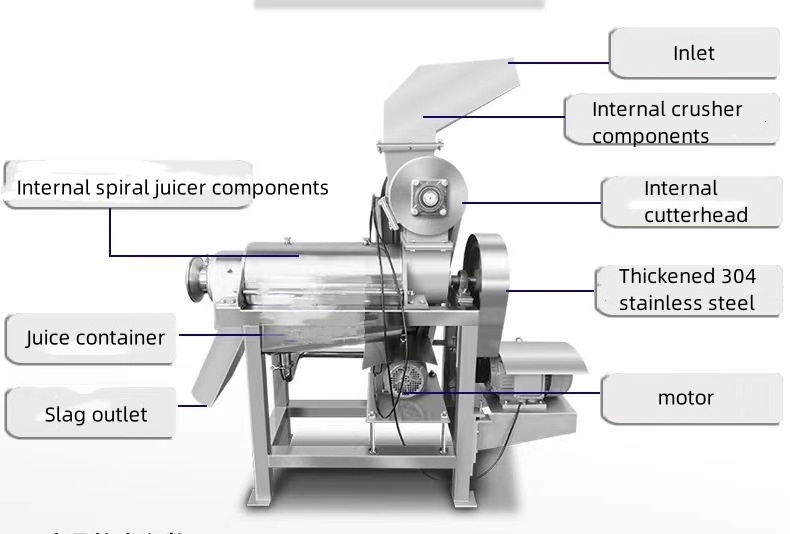

1. This equipment consists of a crusher and a spiral juicer. The crusher is installed on the feed port of the juicer. The crushed materials fall directly into the juicer for juice extraction.

2. The crusher consists of a cylinder, a flying knife rotor, a bottom knife, a motor, and a pulley. The flying knife rotor rotates at high speed in the gap between the bottom knife; under the combined action of the two, the material is broken and enters the juicer for juice extraction.

3. The juicer consists of a front support, a feed hopper, a spiral, a filter, a juice container, a rear support, a slag discharge chute and other parts.

4. When working, the motor drives the main shaft to rotate at a constant speed through a pair of pulleys. The material is chopped by the high-speed rotating hammer. Due to the centrifugal force, the material comes out of the waist-shaped hole screen, so that the fruits and vegetables can reach a particle size of 2-5 mm and are crushed directly into the machine. Spiral juicing system to improve juicing results. The main component of spiral juice extraction is the spiral. The bottom diameter of the spiral gradually increases along the direction of the slag outlet and the pitch gradually decreases. When the material is pushed by the spiral, the volume of the spiral cavity shrinks, causing the material to be squeezed. 5. The raw materials are added to the feeding hopper and are pressed by the advancement of the screw. The squeezed juice flows into the juice container at the bottom through the filter, while the waste materials are discharged through the annular gap formed between the screw and the pressure-regulating conical part. The axial movement of the pressure regulating head can adjust the size of the gap. Change the size of the gap, that is, adjust the resistance to slag discharge

Product Paramenters

|

model

|

capacity(kg/h)

|

power

|

Dimensions

|

feed inlet

|

Juice outlet tube

|

Slag discharge opening width

|

|

DRB-PS0.5T

|

300-500

|

3+2.2

|

1100*450*1550

|

170*135*140

|

DN30

|

140

|

|

DRB-PS1.5T

|

800-1500

|

1.5+4

|

1560*580*1470

|

170*135*140

|

DN30

|

140

|

Main Structure

Feature:

Applications:

Hot Searches