- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Depend on configuration

-

Weight:

-

KG

-

Dimension(L*W*H):

-

Accord to configuration

-

Production capacity:

-

250-1500kg/h

-

Core production technique:

-

Co-rotation twin-screw extrusion

-

Extruder type:

-

Twin-screw extruder

-

Dryer heating type:

-

Electrical, oil-fired, gas-fired, steam

-

Service:

-

On-site service and long-distance service

-

Main production factors:

-

Temperature, pressure, moisture, speed (all can be controlled)

-

Machines main materials:

-

Stainless steel, 38CrMoAl, 45# steel

-

Main food materials:

-

Low-temperature soy flakes (flour), isolated protein, gluten

-

Food shape:

-

Chunk, stick, curl, flake, ball

-

Workers quantity:

-

2-4 workers

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shengrun

-

Voltage:

-

208/220/380/400/415/440/480V

-

Power:

-

Depend on configuration

-

Weight:

-

KG

-

Dimension(L*W*H):

-

Accord to configuration

-

Production capacity:

-

250-1500kg/h

-

Core production technique:

-

Co-rotation twin-screw extrusion

-

Extruder type:

-

Twin-screw extruder

-

Dryer heating type:

-

Electrical, oil-fired, gas-fired, steam

-

Service:

-

On-site service and long-distance service

-

Main production factors:

-

Temperature, pressure, moisture, speed (all can be controlled)

-

Machines main materials:

-

Stainless steel, 38CrMoAl, 45# steel

-

Main food materials:

-

Low-temperature soy flakes (flour), isolated protein, gluten

-

Food shape:

-

Chunk, stick, curl, flake, ball

-

Workers quantity:

-

2-4 workers

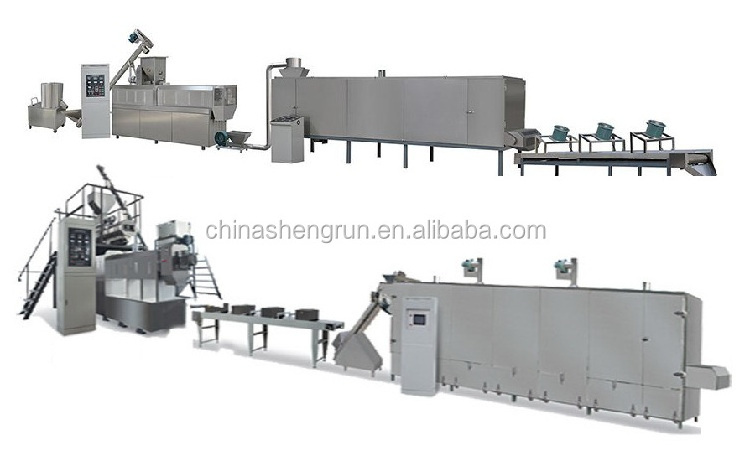

Vietnam vegetarian soy food TSP TVP production line high-speed mixer, double-screw extruder, and multi-layer dryer

1. Processing line introduction

This protein processing line is mainly made up with raw materials treatment system, extrusion system, drying system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extrudate through various means to control the texture of the final product.

This line’s core technology is co-rotating twin-screw extrusion. Twin-screw extruder is the core of this line, enabling the continuous production of expanded snack.

2. Processing line description

2.1 Flow chart: raw materials→ extrusion→ drying→ cooling→ packing

2.2 Processing line features

2.2.1 High work efficiency, automation degree, materials usage, application range.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 Various finished products sizes and shapes.

2.2.5 Production factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 All machines and fittings can be custom-made. ODM or OEM is available.

2.2.8 Professional pre-sale, sale and after-sale service.

2.2.9 Extruder adopts full composite screws, it is made up with screw joints, retaining rings and kneading blocks. The material is 38CrMoAl, which is treated by nitriding. The screws can

2.3 Processing line parameters

|

Type |

Model |

Capacity (kg/h) |

Installed

|

Actual

|

|

|

Dry

|

TSE65-S |

200-250 |

105 |

75 |

|

|

TSE85-S |

450-600 |

210 |

140 |

||

|

Wet

|

TSE90-S |

800-1200 |

140 |

110 |

|

|

TSE95-S |

1000-1500 |

165 |

120 |

2.4 Processing line machines pictures

2.4.1 Series extruders

2.4.2 Series dryers

3. Textured soy protein samples introduction

Textured soy protein, often called TSP (TVP), is made from soy protein concentrate by giving it some texture. TSP is available as dry flakes or chunks. It will keep its structure when hydrated. Hydrated textured soy protein chunks have a texture similar to meat. It can be used as a meat replacement or can be added to meat. Textured soy protein contains about 50-70 percent protein. Recently the popularity of textured soy protein is increasing, mainly because of its health benefits. It has been proven that textured soy protein can help to prevent heart problems and many countries allow health claims for food, which are rich in soy protein.

4. Packing and delivery

4.1 Packed by plastic protective film or wooden case, which is seaworthy.

4.2 We can supply fumigation package and certificate.

5. Service

5.1 1 year warranty period.

5.2 Supply free fittings and general tool.

5.3 Engineers available to service machinery overseas.

5.4 Supply formula of raw materials.

5.5 Workshop design suggestion.