- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

soybean oil extraction plant

-

Voltage:

-

220/380/440

-

Power:

-

40-80kw

-

Dimension(L*W*H):

-

depend on the capacity

-

Weight:

-

depend the capacity on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

soybean, cotton seed, sunflower seed, peanut

-

Capacity:

-

from 1T to 2000T

-

Processing Types:

-

Pre-treatment line & extraction line

-

Solvent:

-

n-hexane

-

Oil residues:

-

less than 1%

-

Warranty:

-

12 months

-

Material of equipment:

-

stainless steel and carbon steel

-

Manufacturing experience:

-

40 years experience

-

Certification:

-

CE&ISO&BV

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Doing

-

Model Number:

-

soybean oil extraction plant

-

Voltage:

-

220/380/440

-

Power:

-

40-80kw

-

Dimension(L*W*H):

-

depend on the capacity

-

Weight:

-

depend the capacity on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

soybean, cotton seed, sunflower seed, peanut

-

Capacity:

-

from 1T to 2000T

-

Processing Types:

-

Pre-treatment line & extraction line

-

Solvent:

-

n-hexane

-

Oil residues:

-

less than 1%

-

Warranty:

-

12 months

-

Material of equipment:

-

stainless steel and carbon steel

-

Manufacturing experience:

-

40 years experience

-

Certification:

-

CE&ISO&BV

Henan Doing Mechanical Equipment Co., Ltd is one leading producer of oil equipments in our country, also one unit exempt from quality examination. Our company service includes technology design, installation and debugging, technical training, relocation of oil plant, technology reform and turnkey project.

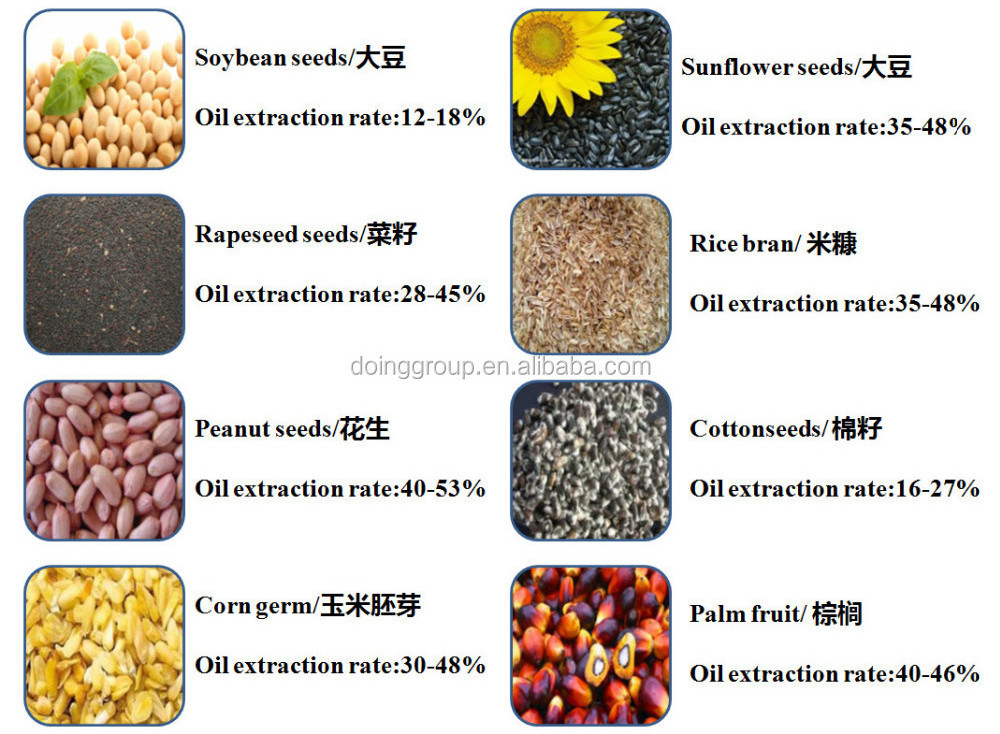

Oil seeds and oil extraction rate

Soybean oil etraction plant

Generally, there are two ways of the process soybean oil, one is the press way, the other is extraction way.

Tow ways contrast

Pressing way :

soybean oil pretreatment machines and press machine

Extraction way:

Soybean oil extraction process

Rotocel extractor

is using oil extraction method and choosing an organic solvent which can dissolve oil, after contacting with pretreated oil--spray or immersion, so that oil can be extracted. As the boliling point of solvent and oil are different, after evaporation and stripping, the solvent are evaporating and we can

get crude oil.

Loop type extractor

adopts a chain-drive system, it is suitable for the prepressing and extraction of high content oil and the direst extraction of low content oil. Like the rotocel extractor, the structure of loop type extractor is designed to reduce power consumption, maintenance requirements and noise.

The advantages of soybean oil extraction way:

Compared with pressing, solvent extraction has higher oil yeild and lower labor cost with better work environment and better-quality cake.

There are 2 tupes of solvent extraction, direct solvent extraction and pre-pressing extraction. Direct solvent extraction is always used for low-oil-content oil seeds, while pre-pressing extraction is used for high-oil-content oil seeds.

Solvent extraction process as follows:

1. Oil extraction:

Oil extraction is to extract oil from oil oil base or pre-pressed cake to oil mixture and meal.

The major equipment of this section is extractor, and extraction pot is always used in batch extraction while continuous extraction uses loop type extractor, rotocel extractor, crawler type extractor, etc.

2. Desolventizer toaster:

Meal from extractor consists of 25-35% solvent. And in order to recycle solvent and get better-quality meal, wet meal drying is necessary.

And high bed desolventizer toaster is always used in pre-pressed leaching meal, while DTDC desolventizer toaster is always used for direct extraction meal.

3. Oil stripping tower/ oil stripper:

Oil mixture consists meal powder, solvent and oil. This step is to seperate these 3 indreginents by filtration, evaporation, and stripping.

The major equipments for this section include filter, cyclone hydraulic separators, evaporator, stripping tower, etc.

We can help you design or choose the most suitable equipment according to your capacity.

4. Solvent vapor condensation and recovery:

Mixed vapor from desolventizer toaster, evaporator, and stripping tower should first be condensed to liquid by condensers, and then seperate solvent and water by water separator, and finally get recycled solvent to reuse in extraction.

We can offer whole line of solvent extraction for different capacity. If you want to know more about solvent extraction workshop, please feel free to contact us.

If you want to get edibel soybean oil , you have to buy vegetable oil refining plant .

1. Delivery 2. Machine installation 3. After-sale Service

After receiving customer’s deposit. We begin the mass production, after finished the production, we load the

machines for customers.

We send technician for each set

of oil mill plant for guiding your installation, testing the machine and training your workers.

Warranty of oil mill plant is one year for free.