- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220~480V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NAVAN Filling Machine

-

Dimension(L*W*H):

-

2000*1450*2200mm

-

Weight:

-

1500 KG

-

Warranty of core components:

-

2 Year

-

Keywords:

-

Small Bottle Drinking Mineral Water Production Line

-

Function:

-

Bottle Blowing Rinsing Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000BPH

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Small and Medium Beverage / Water Factory

-

Control:

-

PLC+ Touch Screen

-

Filling range:

-

200-2000ml

-

Machine type:

-

Gravity Water Filling Machine

-

Machine type 1:

-

Flow meter water filling machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Wood, Other

-

Filling Material:

-

Water, Komcbucha, mineral water, alkaline water, spring water, pure water, soda water

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220~480V 50-60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NAVAN Filling Machine

-

Dimension(L*W*H):

-

2000*1450*2200mm

-

Weight:

-

1500 KG

-

Warranty of core components:

-

2 Year

-

Keywords:

-

Small Bottle Drinking Mineral Water Production Line

-

Function:

-

Bottle Blowing Rinsing Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000BPH

-

Material:

-

Stainless Steel 304/316

-

Suitable for:

-

Small and Medium Beverage / Water Factory

-

Control:

-

PLC+ Touch Screen

-

Filling range:

-

200-2000ml

-

Machine type:

-

Gravity Water Filling Machine

-

Machine type 1:

-

Flow meter water filling machine

NAVAN Machine.

We are one of the earliest companies engaged in manufacturing liquid filling and packing equipment in China. Our products include: Liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), Barreled filling line (3-5 gallon) Water treatment machines, Labeling & packing machines, semi-automatic /full automatic bottle blowing machines, and injection molding machines.Navan Machinery can provide turn-key services for customers, from plant layout, equipment manufacture and production line setup to operator training.

Final Products

|

Equipment Type

|

Automatic

|

|

Bottle Type |

PET round or square bottle

Volume 200 - 2500ml Bottle diameter 50-115mm Bottle height 160-350mm |

|

Output

|

up to 36,000 BPH

|

|

Your product

|

mineral water/pure water/non-gas wine drink and so on.

|

Products Description

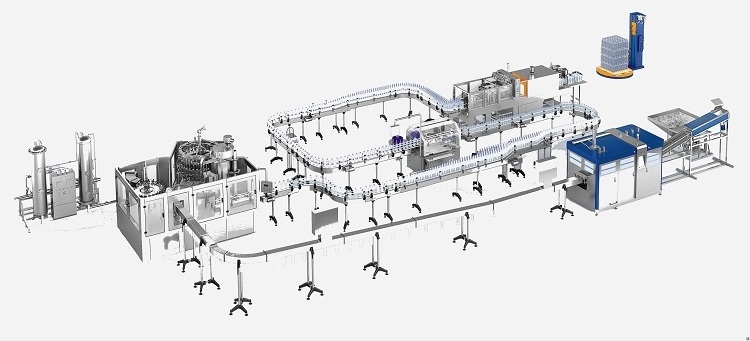

Complete Automatic PET Plastic Small Bottle Drinking Mineral Water Production Line / Bottle Water Filling Machine

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimisation. Whether you're producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

Small and Medium Beverage Factory

We are devoted to supplying complete solution for the water filling plant ,including Water treatment system / Washing filling capping machine / liquid nitrogen dosing system / Auto Bottle Checker / Bottle Blow Dryer / Laser Inkjet Printer / Automatic labeling machine / Automatic packing machine / Automatic Conveyor System / Automatic Palletizer system and other auxiliary equipment such as transformer , electric generator , steam boiler , CIP cleaning system forklift truck .... etc

One partner for all your needs.

A complete water production line solution from NAVAN Machine leverages our knowledge of the entire water bottling process, from minimising waste of resources, to ensuring that your bottle is durable and attractive to consumers. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This

ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

Different water filling machine capacities

8-8-4 Bottle Water Filling Machine Capacity:2000-3000 bottles per hour.

12-12-6 Bottle Water Filling Machine Capacity:3000-4000 bottles per hour.

18-18-6 Bottle Water Filling Machine Capacity:6000-8000 bottles per hour.

24-24-8 Bottle Water Filling Machine Capacity:10000-12000 bottles per hour.

32-32-10 Bottle Water Filling Machine Capacity:16000-18000 bottles per hour.

40-40-12 Bottle Water Filling Machine Capacity:20000-22000 bottles per hour

50-50-15 Bottle Water Filling Machine Capacity:24000-26000 bottles per hour

60-60-15 Bottle Water Filling Machine Capacity:34000-36000 bottles per hour

Boosting speed and hygiene ,

Full Set Complete Automatic PET Plastic Small Bottle Drinking Mineral Water Production Line / Bottle Water Filling Machine

:

1 - Water packing solutions to reduce your total cost of ownership

2 - Higher speeds with gentler handling

3 - Hygienic production for top quality water

4 - Reduced consumption with more efficient resources use

2 - Higher speeds with gentler handling

3 - Hygienic production for top quality water

4 - Reduced consumption with more efficient resources use

Would like to know more about NAVAN Machine equipments, feel free to send us an inquiry!

Product Paramenters

|

Model

|

CGF8-8-8-3/4

|

CGF12-12-5/6

|

CGF18-18-6

|

CGF24-24-8

|

||||

|

Application

|

Spring water / mineral water / pure water / non-gas wine drink and so on

|

|

|

|

||||

|

No. of Rinsing/Filling/Capping

|

8-8-3/4

|

12-12-5/6

|

18-18-6

|

24-24-8

|

||||

|

Production Capacity(500ml)

|

2000BPH

|

4000BPH

|

6000-7000BPH

|

10000~12000BPH

|

||||

|

Filling precision

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

||||

|

User Ambient Conditions

|

Temperature:10~40℃; Humidity: No dew

|

|

|

|

||||

|

Suitable bottle specification

|

Volume=100-2000ml

Diameter φ=50-100mm

Bottle height H=150 ~340mm

|

Volume=100-2000ml

Diameter φ=50-105 Bottle height H=150 ~340mm |

Volume=100-2500ml

Diameter φ=50-115mm

Bottle height H=150 ~350mm

|

Volume=100-2500ml

Diameter φ=50-115 Bottle height H=150 ~350mm |

||||

|

Bottle type

|

Plastic bottle / PET Bottle

|

|

|

|

||||

|

Bottle neck/Cap Style

|

Plastic Screw Cap φ=20-50mm

|

|

|

|

||||

|

Machine material

|

Food stage SS304 OR SS316

|

|

|

|

||||

|

Air source pressure

|

0.5~0.6Mpa

|

|

|

|

||||

|

Filling way/principle

|

Gravity filling method

|

|

|

|

||||

|

Control system

|

SIMENS PLC+ TOUCH SCREEN

|

|

|

|

||||

|

Features

|

No Bottle No Filling No Bottle No Capping

|

|

|

|

||||

|

Main Power

|

1.9kw

|

3.5kw

|

4.0kw

|

4.8kw

|

||||

|

Power Supply

|

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement

|

|

|

|

||||

|

Overall dimensions (mm)

|

1900*1420*2000

|

2050*1800*2400

|

2580*2100*2200

|

2780*2200*2200

|

||||

|

Weight (kg)

|

1500

|

2500

|

3500

|

4500

|

||||

|

All machines could be customized , we could design and produce machines according to your request.

|

|

|

|

|

||||

|

Model

|

CGF32-32-10

|

CGF40-40-10/12

|

CGF50-50-12/15

|

CGF60-60-15

|

||||

|

Application

|

Spring water / mineral water / pure water / non-gas wine drink and so on

|

|

|

|

||||

|

No. of Rinsing/Filling/Capping

|

32-32-10

|

40-40-10/12

|

50-50-12/15

|

60-60-15

|

||||

|

Production Capacity(500ml)

|

16000-17000BPH

|

19000-20000BPH

|

23000-24000BPH

|

34000~36000BPH

|

||||

|

Filling precision

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

≤±5mm(liquid level)

|

||||

|

User Ambient Conditions

|

Temperature:10~40℃; Humidity: No dew

|

|

|

|

||||

|

Suitable bottle specification

|

Volume=100-2500ml

Diameter φ=50-115mm Bottle height H=150 ~350mm |

|

|

|

||||

|

Bottle type

|

Plastic bottle / PET Bottle

|

|

|

|

||||

|

Bottle neck/Cap Style

|

Plastic Screw Cap φ=20-50mm

|

|

|

|

||||

|

Machine material

|

Food stage SS304 OR SS316

|

|

|

|

||||

|

Air source pressure

|

0.5~0.6Mpa

|

|

|

|

||||

|

Filling way/principle

|

Gravity filling method

|

|

|

|

||||

|

Control system

|

SIMENS PLC+ TOUCH SCREEN

|

|

|

|

||||

|

Features

|

No Bottle No Filling No Bottle No Capping

|

|

|

|

||||

|

Main Power

|

5.5kw

|

7.5kw

|

11.0kw

|

15.0kw

|

||||

|

Power Supply

|

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement

|

|

|

|

||||

|

Overall dimensions (mm)

|

3800*2800*2600

|

4600*2800*2600

|

5450*3300*2600

|

6500*4500*2600

|

||||

|

Weight (kg)

|

6500

|

8500

|

9800

|

12800

|

||||

|

All machines could be customized , we could design and produce machines according to your request.

|

|

|

|

|

||||

Details Images

1-NAVAN Machine RO Water Treatment System

*

Raw water tank + Raw water pump

* Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

* Reverse Osmosis (one level)

* UV sterilizer

* Finished water tank + Pure water pump

* Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

* Reverse Osmosis (one level)

* UV sterilizer

* Finished water tank + Pure water pump

2 - NAVAN Machine Blow Molding Machine.

1 / Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

3-CGF Bottle Water Filling Machine [ Washing Filling Capping 3 in 1 Monoblock Machine ]

CGF series of machines are full-automatic multiple-function washing , filling, capping unit . It is used in washing ,filling ,capping all kinds of non-gas drink, such as vinegar ,wine, fruit wine, mineral water , pure water .

This filling and packing equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing ,filling ,capping .Most of elements of the electric system employ famous brand products .The machines parts contact the liquid are made of high quality stainless steel .They obtain the advantages of good abrasive resistance , high stability ,low failure rate ,etc. The quality of the equipment reach the international advanced level and gained good reputation among our clients .

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

5 / Automatic dummy bottles: Safer, easier cleaning procedures

6 / Automatic bottle changeover improves uptime

OPP Rotary Labeling Machine

Shrink Sleeve Labeling Machine

Adhesive Labeling Machine

4 - NAVAN Machine Bottle Labeling Machine.

Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 36,000

containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

finished product display

Automatic Carton Packing Machine with hotling glue

L Type Film Wrapping Packing Machine

Linear Type Film Wrapping Packing Machine

5 - NAVAN Machine Bottle Packing Machine.

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale, so it needs to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes.Whether you choose shrink-printed film, nested packs or wraparound cartons, NAVAN Machine packers gently feed bottles to ensure durable and cost-effective packs.

BENEFITS.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

BENEFITS.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Would like to know more about NAVAN Machine equipments, feel free to send us an inquiry!

Finished Product Display

NAVAN Factory Competitive Prices Water Lines Solution for PET 200-2000ml Bottle

Recommend Products

Best Service

Options & Upgrades.

Beverage producers need to be able to meet the demands of an evolving beverage industry, and NAVAN Machine is committed to ensuring optimal productivity and performance over your line's entire lifetime. With NAVAN Machine Options & Upgrades, new technologies or refurbished components help to maintain or even improve performance - without replacing your entire line.

Options: New functionalities that optimise flexibility and costs

Upgrades: New technologies that improve performance, safety, hygiene and resource savings

Since we built your line, we have a comprehensive understanding of its design, and our engineering experts can analyse equipment and processes to determine how to strengthen performance. As new technologies and solutions are introduced to the market, we ensure that your production benefits accordingly, so you can stay on target in a changing, competitive marketplace.

NAVAN Machine Options & Upgrades helps you:

1 - Boost product quality

2 - Increase efficiency

3 - Reduce Total Cost of Ownership

4 - Future-proof your productivity

5 - Browse our online catalogue

Options: New functionalities that optimise flexibility and costs

Upgrades: New technologies that improve performance, safety, hygiene and resource savings

Since we built your line, we have a comprehensive understanding of its design, and our engineering experts can analyse equipment and processes to determine how to strengthen performance. As new technologies and solutions are introduced to the market, we ensure that your production benefits accordingly, so you can stay on target in a changing, competitive marketplace.

NAVAN Machine Options & Upgrades helps you:

1 - Boost product quality

2 - Increase efficiency

3 - Reduce Total Cost of Ownership

4 - Future-proof your productivity

5 - Browse our online catalogue

Label Design.

We can provide the label design according to the bottle size, the icon style you want.

Bottle Design.

Our designers can design bottle styles according to your requirement.

Machine Layout.

We will design andconfirm the machine layout according to your factory sketch.

Why Choose Us

NAVAN Machinery.

Factory Show.

<1> Standardized workshop of total 3,000 square meters.

<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacities and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in the shortest time.

Certificates.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS-COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Customers.

We are a professional manufacturer of beverage machinery in China

. With the scientific progressive conception of rapid introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality.

FAQ

Q 1 When can I get installation from you? how much the cost?

When you finish the preparation conditions(water resource,electricity,air supply,production materials) according to our designed layout , please contact with our sales manager, we will dispatch engineer to you.

Inspect and improve connection jobs together with your team .

Guide your staff to operate machines , and explain how to operate and maintain machines .

Collected your your comments on our machines , we will send feedback to our technical team to improve our machines continuously.

The customer should be responsible for the room, meals and board and the two-way air tickets and visa and fee as well the allowance 150 ~200 USD per day for each person. And should be also responsible for the engineer’s personal safety.

Note: Normally when your preparation is done,you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 15 days more or less .

Q 2 How long time for installation?

According your machines order,we will send one or two engineers to your plant,it will take about 15 days to 30 days.

Q 3 When can I get my machine after I paid?

Normally production time is around 30-60days , it depends on your ordered machines and quantity .

The shipping time is based on your destination port.(Usually we use Shanghai port , Ningbo Port as loading port )

Q 4 How about the spare parts?

We will send one year enough easy broken spare parts together with the machines together when delivery.

During the warranty time, we will supply the spare parts with our cost price including and delivery fees.

Q 5 What`s your payment term?

We accept TT , TT/LC/Western union.etc

Q 6 What`s your delivery term?

We provide EXW,FOB,CFR,CIF ... etc delivery terms.

Q 7 How to test machine before delivery?

We will connect all machines in line make them running over 8 hours non-stop , then take and send testing videos. Or we could live video inspection .

Q 8 How about the Packaging details?

Standard export packing to ensure that the product packaging integrity and safety. ( Heavy products adopt export plywood case packing with waterproof film . Small products use thick carton packing waterproof film)

Q 9 Do you have reference project?

We have reference project in most countries. After getting the permission of the customer who has brought the machines from us ,we will send you their contact information and arrange your visiting to their factory.

And you are always welcome to come to visit our factories ,and inspect the machine running in our factory .We will be glad offer necessary supports on hotel booking , transportation , VISA application. OR you can get video of our reference running machine on our website too .

Q 10 Do you provide turnkey project?

YES Turnkey project is available .We can help you to start a new beverage / water factory from A to Z.

Q 11 Do you have agent and after-service stations?

So far we have agent in Kampala ,Uganda and Dubai ,UAE .You are mostly welcomed to join us!

Q 12 Do you have any certificate?

We have been certificated by the famous certification authority such as CE , ISO, SGS ...etc

Q 13 Do you provide customized service?

We are able to develop the machines according your requirements(material ,power,filling type,the kinds of the bottles,and so on),at the same time we will offer you professional advice based on our 30+ years beverage machine industrial experience.

Q 14 What`s your guarantee or the warranty of the quality if we buy your machines?

We offer you high quality machines with 1 year guarantee and supply life-long technical support for free .

Hot Searches