Simple operation panel,it can be customized in different kinds of language.

The visual working data makes it easier to test and adjust the machine helps to save time. We use imported operation panel which

improves the product qZZuality.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2ml

-

Voltage:

-

380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingstar

-

Dimension(L*W*H):

-

2800*2100*2200

-

Weight:

-

4000 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Function:

-

Washing Filling Capping

-

Usage:

-

Liquid Filling Packaging

-

Keywords:

-

Fillng Machine

-

Feature:

-

Durable

-

Advantage:

-

High Effiency

-

Packing material:

-

PE.PET

-

Control:

-

PLC+ Touch Screen

-

Production capacity:

-

2000-15000bph

-

Material:

-

304 Stainless Steel

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 6000BPH, Other

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water, Juice

-

Filling Accuracy:

-

2ml

-

Voltage:

-

380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Mingstar

-

Dimension(L*W*H):

-

2800*2100*2200

-

Weight:

-

4000 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Function:

-

Washing Filling Capping

-

Usage:

-

Liquid Filling Packaging

-

Keywords:

-

Fillng Machine

-

Feature:

-

Durable

-

Advantage:

-

High Effiency

-

Packing material:

-

PE.PET

-

Control:

-

PLC+ Touch Screen

-

Production capacity:

-

2000-15000bph

-

Material:

-

304 Stainless Steel

Product Description

This CGF series bottling machine, incorporates rinsing, filling and capping. into one and is a kind of full-automatic equipment.

It is innovated and designed in the requirement of still pure water and mineral water, on the bases of introducing, digesting and

absorbing advanced technology from Germany and Italy.

CGF series bottle water filling machine is used to fill mineral water, pure water, purified water, spring water into PET bottle

from 200ml-2000ml. Glass bottle is also suitable, just need to change the conveyor parts.

Different models can satisfy various requirement of output from 3000B/H to 36000B/H.

The whole process of water filling production line is automatic, suitable for PET bottle, plastic bottle filling mineral water and

pure water.

It is innovated and designed in the requirement of still pure water and mineral water, on the bases of introducing, digesting and

absorbing advanced technology from Germany and Italy.

CGF series bottle water filling machine is used to fill mineral water, pure water, purified water, spring water into PET bottle

from 200ml-2000ml. Glass bottle is also suitable, just need to change the conveyor parts.

Different models can satisfy various requirement of output from 3000B/H to 36000B/H.

The whole process of water filling production line is automatic, suitable for PET bottle, plastic bottle filling mineral water and

pure water.

Main Technical Parameters

Take water as the main parameter for reference, other liquids, please contact customer

service for details

service for details

All machines could be customized , we could design design and produce machines according to your request.

|

Model

|

CGF8-8-3

|

CGF14-12-5

|

CGF16-16-6

|

CGF24-24-6

|

|

Production capacity

|

3000BPH(500ml)

|

5000BPH(500ml)

|

8000BPH(500ml)

|

12000BPH(500ml)

|

|

Washing heads

|

8

|

14

|

16

|

24

|

|

Filling heads

|

8

|

12

|

16

|

24

|

|

Capping heads

|

3

|

5

|

6

|

6

|

|

Suitable bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

PET bottle,

Plastic bottle

|

|

Diameter of bottle

|

50-110mm

|

50-110mm

|

50-110mm

|

50-110mm

|

|

Height of bottle

|

150-310mm

|

150-310mm

|

150-310mm

|

150-310mm

|

|

Suitable cap

|

Plastic screw cap

|

Plastic screw cap

|

Plastic screw cap

|

Plastic screw cap

|

|

Weight

|

1500KG

|

2000KG

|

4500KG

|

6000KG

|

|

Main motor power

|

1.5KW

|

1.5KW

|

3KW

|

3KW

|

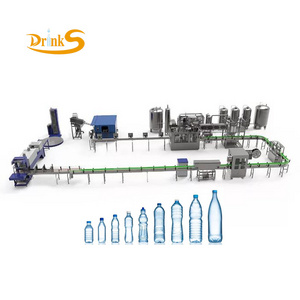

This Production Line is a whole Automatic water filling capping machine production line solution;The Machine Type, Number Of Machines, Speed, Capacity, Size, Etc. Of The Production Line Would Be Customized According To The Customer'S Production Needs; We Can Develop A Professional Integrated Filling And Packaging Production Line Plan For The Customer.

Please contact us to confirm the product parameter before payment.

Detailed Images

Operation Panel

The total machine uses advanced photoelectric detection technology to detect each parts operation status, no bottle no filling, and no bottle no capping, automatic and easy operation.

Washing Parts

Into bottle way is air conveyor direct connection with bottle dial.All

-304/316 stainless steel rinse heads,water spray style inject design, more save water consumption and more clean.

-304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

-304/316 stainless steel washing pump make the machine more durable.

-304/316 stainless steel rinse heads,water spray style inject design, more save water consumption and more clean.

-304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

-304/316 stainless steel washing pump make the machine more durable.

Filling Parts

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Place and capping system, electromagnetic capping heads, with burden discharge

function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Auxiliary Parts

The auxiliary(optional)equipment have boottle rinsing water reflux tank,bottle-feeding air conveyor,and bottle-outputting chain.

Besides,we will configure manual bottle feeding platform (or bottlle unsrambler),automatic cap elecator and so on.

Besides,we will configure manual bottle feeding platform (or bottlle unsrambler),automatic cap elecator and so on.

Related Products

What We Offer?

Consultation Service

Filling Machine Choosing

Filling Machine Customization

Filling Line Updating

Turn-Key Solution

Manufacture & Test Service

Filling Machine Stress Testing

Packing & Logistic

SGS Certification

Technical Support

After Sales Service

Installation & Worker Training

Technical Support Online

Annual Diagnosis & Updating

Optional Value-added Service

Agent Recruitment Programme

Client Guarantee Programme

Customer Development Programme

Label Design.

We can provide the label design

according to the bottle size, the

icon style you want.

Bottle Design.

Our designers can design bottle

styles according to your

requirement.

Machine Layout.

We will design andconfirm the

machine layout according to

your factory sketch.

Hot Searches