- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

10-40 bags/min

-

Weight (KG):

-

1200

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK Machine

-

Dimension(L*W*H):

-

2450(L)*1350(W)*1350(H)mm (single host)

-

Product name:

-

Liquid doypack packing machine

-

Keyword:

-

Premade bag packing machine

-

Main Function:

-

Packing filling sealing

-

Bag type:

-

Stand-up bag, zipper pouch, spout bag, premade bag, etc.

-

Packing range:

-

200-2000ml

-

Bag length:

-

160-380mm

-

Bag width:

-

140-260mm

-

Packing speed:

-

10-40 bags/min

-

Machine size:

-

2450(L)*1350(W)*1350(H)mm (single host)

-

Power:

-

380V, 50/60Hz, 4.5kw

Quick Details

-

Function:

-

FILLING, Labeling, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic

-

Production Capacity:

-

10-40 bags/min

-

Weight (KG):

-

1200

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MK Machine

-

Dimension(L*W*H):

-

2450(L)*1350(W)*1350(H)mm (single host)

-

Product name:

-

Liquid doypack packing machine

-

Keyword:

-

Premade bag packing machine

-

Main Function:

-

Packing filling sealing

-

Bag type:

-

Stand-up bag, zipper pouch, spout bag, premade bag, etc.

-

Packing range:

-

200-2000ml

-

Bag length:

-

160-380mm

-

Bag width:

-

140-260mm

-

Packing speed:

-

10-40 bags/min

-

Machine size:

-

2450(L)*1350(W)*1350(H)mm (single host)

-

Power:

-

380V, 50/60Hz, 4.5kw

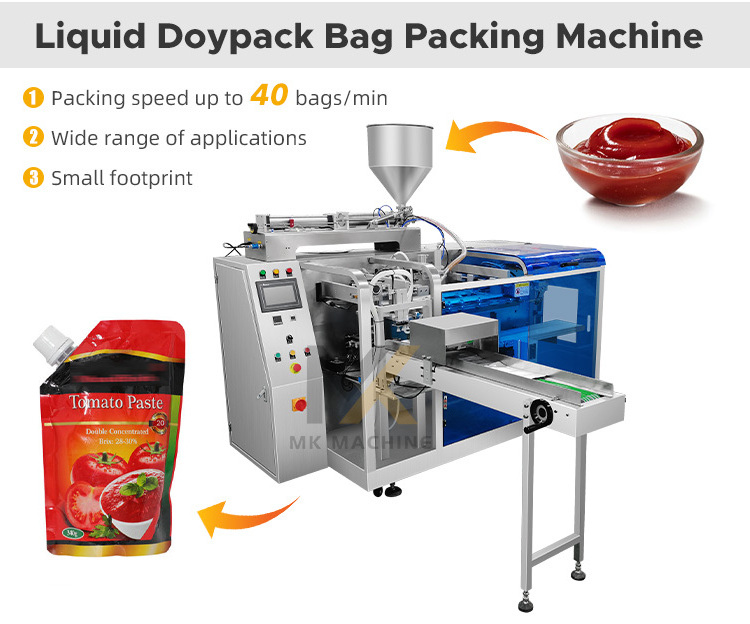

Automatic premade bag liquid chilli paste ketchup tomato sauce pouch packaging machine

CUSTOMER FOCUS

We are committed to understanding our customers’ needs and providing solutions that add value.

TECHNOLOGY R&D

The technical research and development team provides a variety of packaging solutions.

CUSTOMER CASE

We provide automation equipment to 250 companies around the world.

Fully automatic doypack bag packing machine is suitable for liquid material packaging in food, daily necessities and other industries, such as ketchup, tartar sauce, pasta sauce, mayonnaise, honey, soy sauce, broth, milk, juice, sports drinks, Body wash, shampoo, laundry detergent, etc.

Features

1. The whole machine adopts a horizontal layout, which occupies a small area and has high work efficiency.

2. Set packaging parameters through the color touch screen, support multiple languages, and the operation is simple and easy to understand.

3. High degree of automation. In the process of weighing and packaging, it realizes unmanned and automatic alarm for faults.

4. Quick change of packaging bag specification. Automatic belt feeding device, width and size can be automatically adjusted at one time.

5. Low packaging loss. It is suitable for premade bags. The sealing quality is good, high-grade products.

6.

Using famous brand electrical components, the overall quality is guaranteed. The system is stable, high compatibility and long service life.

|

Packing range

|

20-2000ml

|

|

Bag length

|

160-380mm

|

|

Bag width

|

140-260mm

|

|

Packing speed

|

10-40 bags/min

|

|

Machine size

|

2450(L)*1350(W)*1350(H)mm (single host)

|

|

Machine weight

|

1200kg

|

|

Power

|

380V, 50/60Hz, 4.5kw

|

Bag Warehouse

It is suitable for a variety of bag types. The vacuum suction cup is used to take out and open the bag. It has an automatic detection function. If there is no bag, it will stop and reduce waste.

Filling Device

Equipped with fiber optic electric eyes to detect bags to ensure accurate filling position and no material leakage.

Sealing Device

Using intelligent PID independent temperature control, the bag is tightly sealed and does not leak materials.

Foshan Maike Intelligent Equipment Co., Ltd. is the company located in Foshan Guangdong China with 20 years experience in the packing industry. MK MACHINE designs, manufactures and markets Vertical Form-Fill & Seal VFFS Machines, Horizontal Fill & Seal Machines, and an high-speed line of Rotary Machines for Pre-Made Doypack Bags.

An operation video is prepared for you, and a product manual is attached.

Professional engineers provide technical support to customers.Customers can contact us immediately

if they have any questions.

FAQ

1.How to find a solution suitable for my product?

Tell me about your product details: 1. What kind of product you have. 2. the size of your product.

2.How easy is it to operate packaging equipment?

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn't hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does packaging equipment cost?

3.How much does packaging equipment cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at 'standard pricing' isn't usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process.

4.Which machines are available in-stock?

4.Which machines are available in-stock?

If your needs are fairly standard and straightforward, you may be able to snag an In-Stock Machine and get it delivered in just a few weeks! CALL US to ask about our current inventor

y.

5.What is your after sales services?

5.What is your after sales services?

●

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

●

After the commissioning, we will package the equipment by standard export package for shipment.

●

According to the customer's request, we can arrange our engineers to customers' factory to do the

installation and training.

installation and training.

●

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Hot Searches