Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOBO

-

Voltage:

-

220V

-

Weight (KG):

-

1200

-

Maximum punching force:

-

300kn

-

Punching range:

-

4.3-25mm

-

Maximum processing width:

-

150mm

-

Maximum processing thickness:

-

12mm

-

Maximum shear force:

-

400kn

-

Maximum shear thickness:

-

12mm

-

Maximum cutting width:

-

150mm

-

Maximum bending force:

-

300kn

-

Power:

-

3*4kw

-

Weight:

-

1450kg

Quick Details

-

Max. Thickness (mm):

-

12 mm

-

Max. Width (mm):

-

150 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Voltage:

-

220V

-

Weight (KG):

-

1200

-

Maximum punching force:

-

300kn

-

Punching range:

-

4.3-25mm

-

Maximum processing width:

-

150mm

-

Maximum processing thickness:

-

12mm

-

Maximum shear force:

-

400kn

-

Maximum shear thickness:

-

12mm

-

Maximum cutting width:

-

150mm

-

Maximum bending force:

-

300kn

-

Power:

-

3*4kw

-

Weight:

-

1450kg

Product Description

The CNC busbar processing machine is special for processing aluminum and copper busbars. It combines punching, cutting and bending units, and three units can work simultaneously. When operating, choose the appropriate processing unit to proceeding cutting, punching, fold bending, vertical bending, embossing, flatting, twisting.

Features

1. Control the downwards time of shearing and punching, but also has automatic shutdown function.

2.The shearing unit is common double-blade type cutting, cutting edge is smooth without burr.

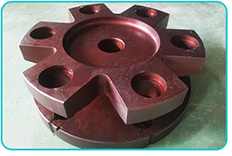

3. The punching unit is turret six-die rotating wheel type made of ductile iron materials improve the concentricity of the dies, to extend the usage life of the dies. Moreover, when using without frequent replacement of the dies, and improve the working efficiency.

4.PLC control, the bending angle can be NC control with save memory function, extremely convenient.

5. The hook-type open bending station is simple and convenient to operate, and can process special back-shaped small bending, embossing, vertical bending, etc.

6. The bending unit adopts horizontal processing, which is safer and more convenient uring processing, and can complete U-shaped bends with a minimum size of 3.5MM.

Details Images

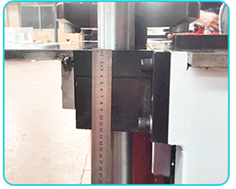

Specification

|

Function

|

Item

|

Parameter

|

|

|

Punching Processing

|

Punching Torce

|

300KN

|

|

|

|

Punching Range

|

4.3-30 mm

|

|

|

|

Thickness

|

15mm

|

|

|

|

Width

|

160mm

|

|

|

Cutting Processing

|

Cutting Torce

|

500KN

|

|

|

|

Thickness

|

15mm

|

|

|

|

Width

|

160mm

|

|

|

Bending Processing

|

Bending Torce

|

300KN

|

|

|

|

Thickness

|

12mm

|

|

|

|

Width

|

150mm

|

|

|

Main motor power

|

|

3*4kw

|

|

|

Machine usage

|

|

For busbar bending punching sharing

|

|

|

Voltage

|

|

380V/220 V/415v/50HZ/60HZ or customed

|

|

|

Packing Size

|

|

1780*1400*1200mm

|

|

|

Weight

|

|

1450kg

|

|

About Us

Trade Assurance

Packing and Shipping

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Hot Searches