- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Power:

-

5-20kW

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

1200*1000*800mm

-

Product name:

-

Milk powder or raw milk to make ice cream

-

Construction material:

-

SUS316L/SUS304

-

ontrol type:

-

automatic

-

Certificate:

-

ISO and CE

-

Energy consumption:

-

Low consumption

-

Effeciency:

-

high effeciency

-

Application:

-

Ice Cream

-

Final product:

-

Flavored Ice Cream

-

Processing Types:

-

Heating + Pasteurizing +cooling

-

Capacity:

-

500kg/hr-1000kg/hr

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Beyond

-

Voltage:

-

220V/380V/415V

-

Power:

-

5-20kW

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

1200*1000*800mm

-

Product name:

-

Milk powder or raw milk to make ice cream

-

Construction material:

-

SUS316L/SUS304

-

ontrol type:

-

automatic

-

Certificate:

-

ISO and CE

-

Energy consumption:

-

Low consumption

-

Effeciency:

-

high effeciency

-

Application:

-

Ice Cream

-

Final product:

-

Flavored Ice Cream

-

Processing Types:

-

Heating + Pasteurizing +cooling

-

Capacity:

-

500kg/hr-1000kg/hr

Milk powder to make Ice cream Ice Cream Processing Machinery Small Ice Cream Plant

Ice cream making machinery refers to the equipment used in the production of ice cream. These machines typically include a variety of components that are designed to mix, freeze, and shape the ice cream mixture.

Some common types of ice cream making machinery include:

Batch freezers: These machines are used to freeze and churn the ice cream mixture. They have a large drum or container that holds the mixture, and an agitator that continuously stirs and scrapes the frozen mixture from the sides of the container.

Continuous freezers: These machines are used for high-volume production of ice cream. They work by continuously pumping the mixture through a freezing chamber where it is rapidly frozen. The frozen mixture is then scraped off and collected as ice cream.

Mixers: Mixers are used to blend the ingredients of the ice cream mixture. They can be as simple as handheld mixers or as complex as large-scale industrial mixers.

Pasteurizers: Pasteurizers are used to heat the ice cream mixture to kill any harmful bacteria before freezing. This process helps to ensure the safety and quality of the ice cream.

Homogenizers: Homogenizers are used to break down fat molecules in the ice cream mixture, resulting in a smoother and creamier texture.

Filling machines: Filling machines are used to package the ice cream into containers, such as tubs, cones, or bars.

These are just a few examples of the different types of machinery used in ice cream production. The specific machinery used will depend on the scale of production and the desired characteristics of the ice cream.

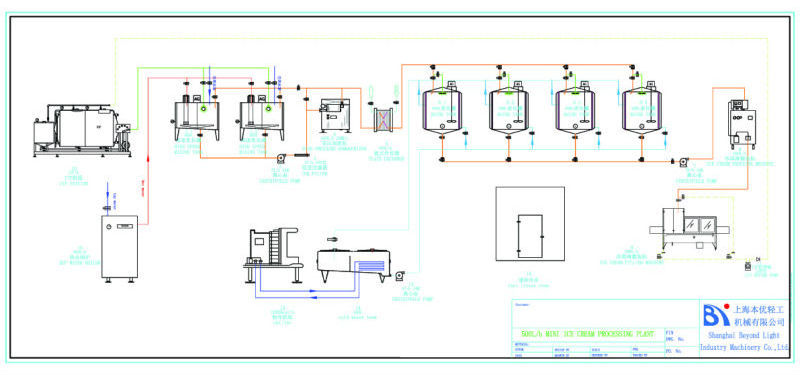

Icecream processing machine Project Photos

Figure shows ice cream products production line.

1. Ice cream mix preparation module containing

2. Water heater

3. Mixing and processing tank

4. Homogeniser

5. Plate heat exchanger

6. Control panel

7. Cooling water unit

8. Ageing tanks

9. Discharge pumps

10. Continuous freezers

11. Ripple pump

12. Filler

13. Manual Can filler,

14. Wash unit

DESCRIPTION

-Formulation:

The ingredients used in ice cream production are: fat

;

milk solids-non-fat (MSNF)

;

sugar/non-sugar sweetener

;

emulsifiers/stabilisers

;

flavouring agents

;

colouring agents.

-Weighing, measuring and mixing:

Generally speaking, all dry ingredients are weighed, whereas liquid ingredients can be either weighed or proportioned by volumetric meters.

-Homogenisation and pasteurisation:

The ice cream mix flows through a filter to a balance tank and is pumped from there to a plate heat exchanger where it is preheated to 73 – 75deg for homogenisation at 140 – 200 bar, the mix is pasteurised at 83 – 85deg for about 15 seconds then cooled down to 5deg and transferred to an ageing tank.

-Ageing:

The mix must be aged for at least 4 hours at a temperature between 2 to 5degc with continuous gentle agitation. Ageing allows time for the stabiliser to take effect and the fat to crystallise.

-Continuous freezing:

•to whip a controlled amount of air into the mix;

•to freeze the water content in the mix to a large number of small ice crystals.

-Filling in cups, cones and containers;

-Extrusion of sticks and stickless products;

-Moulding of bars

-Wrapping and packaging

-Hardening and cold storage

|

equipment list for 500l/h mini ice cream processing machine |

|||

|

no. |

name |

size |

main technology parameter |

|

1 |

high speed mixing tank |

v=300l |

sus304, single layer, high speed mixer 2900rpm, full open removable cover, breath valve, digital thermometer, adjustable legs, sample valve |

|

2 |

centrifugal pump |

q=5t/h |

sus304 , pump head 24m , hard alloy mechanical seal |

|

3 |

tub filter |

q=3t/h |

sus304 , 100 mesh |

|

4 |

high pressure homogenizer |

q=500l/h |

sus304,25mpa |

|

5 |

plate exchanger |

q=500l/h |

sus304 |

|

6 |

ice cream aging tank |

v=500l |

sus304 stainless steel , heat insulated , heating or cooling jacket,top off-center vertical agitator , conical head , airtight manhole , breather valve , digital readout thermometer , supporters with adjustable feet |

|

7 |

centrifugal pump |

q=5t/h |

sus304 , pump lift 24m , hard alloy mechanical seal , inner shell bright-polished |

|

8 |

ice cream freezer machine |

q=500l/h |

sus304 , include refrigeration system |

|

9 |

ice cream filling machine |

q=500l/h |

sus304 , roll icecream filling machine |

|

10 |

cip system |

q=10t/h |

sus304 , 0.5tx3 |

|

11 |

cip return pump |

q=10t/h |

sus304 , pump head 20m , hard alloy mechanical seal |

|

12 |

boiler |

q=500l/h |

sus304 , electric heating type |

|

13 |

refrigerator |

a ir-cooled compressor,with fron as chilling medium,20000kcal |

|

|

14 |

container for glycol water |

v=500l |

sus304 stainless steel material,pu heat insulation,thermometer,adjustable feet |

|

15 |

centrifugal pump |

q=3t/h |

sus304 , pump head 24m , hard alloy mechanical seal |

|

16 |

instant cool room |

v=25m3 |

cool with freon,working at -28 °C |

|

17 |

electrical control pannel |

control all the machines of the mini unit |

|

|

18 |

fittings and valves |

juice pipe,glycol pipe,freon pipe |

|

Service flowchart