- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XCJ, XCJ

-

Model Number:

-

Standard Size

-

Tolerance:

-

-0.01~0.006

-

Helix Angle:

-

45°

-

HRC:

-

HRC45/55/65

-

Application:

-

Side Face/ Step Shoulder/Straight Slot

-

Workpiece Material:

-

Aluminum/Copper/brass etc

-

Machine Type:

-

Walter

-

Suitable for:

-

High Speed Processing

-

Flute:

-

2/4Flutes

Quick Details

-

Material:

-

Carbide, Tungsten Cobalt Alloy

-

Coating:

-

No

-

Warranty:

-

1 years

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XCJ, XCJ

-

Model Number:

-

Standard Size

-

Tolerance:

-

-0.01~0.006

-

Helix Angle:

-

45°

-

HRC:

-

HRC45/55/65

-

Application:

-

Side Face/ Step Shoulder/Straight Slot

-

Workpiece Material:

-

Aluminum/Copper/brass etc

-

Machine Type:

-

Walter

-

Suitable for:

-

High Speed Processing

-

Flute:

-

2/4Flutes

Product Overview

Products Description

XCJ Factory Milling Cutter CNC Tools Endmill Solid Carbide HRC65 Endmill 4 Flute Flat Fresa End Mill1-20mm

|

Product Name

|

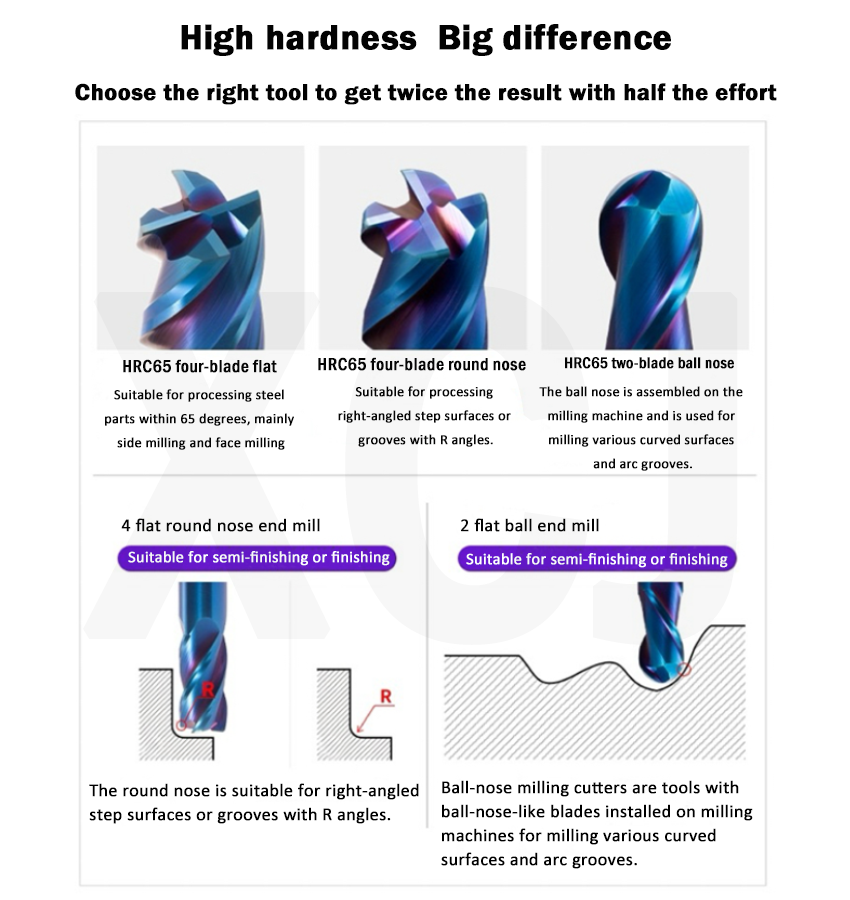

HRC65 4 Flute Flat/2 Flute ball nose/Round nose mill Fresa End Mill

|

|

|

Material

|

Tungsten carbide

|

|

|

Model

|

Standard or your requiement

|

|

|

Flutes

|

2/4 flutes

|

|

|

Coating

|

AlTiN, TiAlN, TiSiN, TiN, Nano blue or DLC

|

|

|

Standard

|

ISO

|

|

|

HRC

|

65

|

|

|

Shank Diameter

|

1mm~20mm

|

|

|

Overall Length

|

50mm-200mm

|

|

|

Helix Angle

|

38/45 degree

|

|

|

Application

|

Stainless steel, carbon steel, alloy steel, copper alloy, ductile iron, pre-hardened steel (< 65HRC), hardened steel, materials below 65 degrees

|

|

|

Machine Type

|

CNC machine, engraving machine, etc

|

|

|

All the specs. can be customized

|

|

|

1. High quality carbide rod(100% Origin Material Tungsten Steel Material):

All cutting materials are from international famous brands, high hardness, long tool life,Good wear resistance.

All cutting materials are from international famous brands, high hardness, long tool life,Good wear resistance.

|

Grade

|

HRC45

|

HRC55

|

HRC60

|

HRC65

|

|

Materials

|

JT30S(Jiangwu)

|

GU25UF(xiamen Jinlu)

|

GU092(xiamen Jinlu)

|

PN90 (Sweden)

|

|

Details

|

Grain size: 0.7um

Co: 10% Flexural strength: 4000N/mm2 |

Grain size: 0.4um

Co: 12% Flexural strength: 4200N/mm2 |

Grain size: 0.2um

Co: 9% Flexural strength: 4200N/mm2 |

Grain size: 0.2um

Co: 9% Flexural strength: 4700N/mm2 |

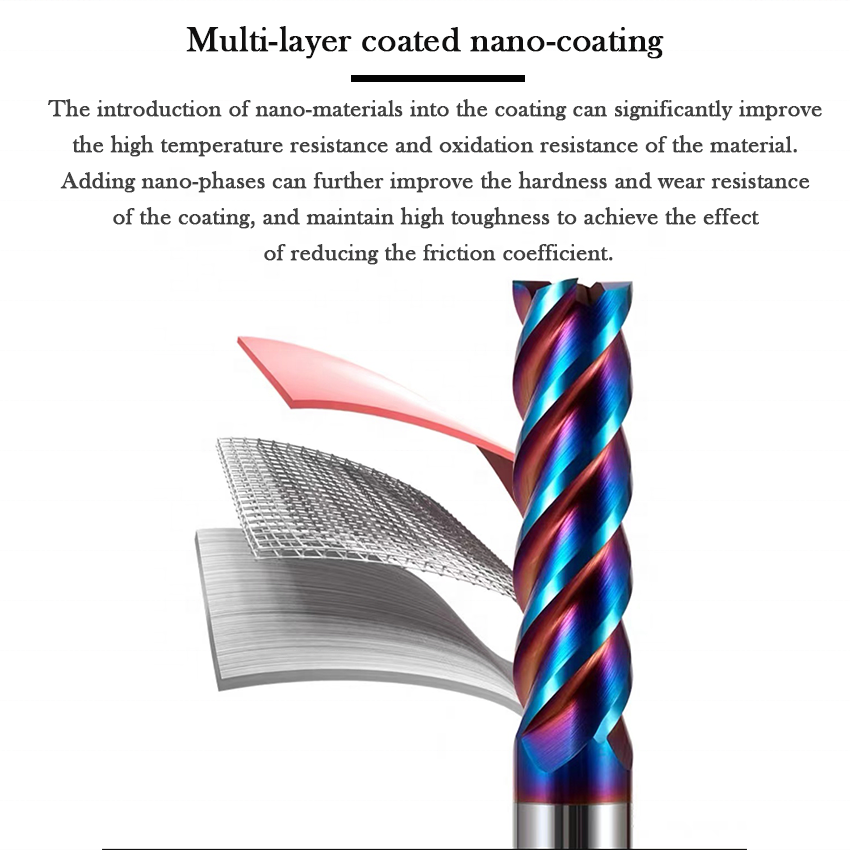

2. Super coating

Good coating can improve tools life and production efficiency, and we provide professional suggestions according to your cutting requirements.

Good coating can improve tools life and production efficiency, and we provide professional suggestions according to your cutting requirements.

|

Item

|

Color

|

Hardness (HV)

|

Thickness (UM)

|

Oxidation Temp.(℃)

|

Friction Coeffient

|

|

AlTiN

|

Black

|

3300

|

2.5-3

|

900

|

0.3

|

|

TiAlN

|

Violet

|

2800

|

2.5-3

|

800

|

0.3

|

|

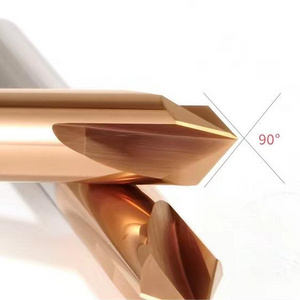

TiSiN

|

Bronze

|

3600

|

3

|

1000

|

0.45

|

|

NaCo

|

Blue

|

42(GPA)

|

3

|

1200

|

0.4

|

|

The main cutting products we sell are as follows:

|

|

|

|

|||

|

◆ Carbide inserts

◆ Solid Carbide End Mills

◆ Turning tool holder

◆ Face Milling Tool

|

|

◆ Drills, reamers, threaded cutters and burrs

◆ CNC tool holder, CNC collet and U Drill

◆ Precision tool vice

◆ Other accessories (CNC wrench, tool cart, lock tool holder, lathe accessories)

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|||

Details Images

|

Specification

|

Flute Dia(φ)

|

Flute Length (C)

|

Shank Dia(D)

|

Overall Length(L)

|

|

Φ1×3×D4×50L

|

1

|

3

|

4

|

50

|

|

Φ1.5×4×D4×50L

|

1.5

|

4

|

4

|

50

|

|

Φ2×5×D4×50L

|

2

|

5

|

4

|

50

|

|

Φ2.5×6×D4×50L

|

2.5

|

6

|

4

|

50

|

|

Φ3×8×D4×50L

|

3

|

8

|

4

|

50

|

|

Φ4×10×D4×50L

|

4

|

10

|

4

|

50

|

|

Φ5×13×D5×50L

|

5

|

13

|

5

|

50

|

|

Φ6×15×D6×50L

|

6

|

15

|

6

|

50

|

|

Φ8×20×D8×60L

|

8

|

20

|

8

|

60

|

|

Φ10×25×D10×75L

|

10

|

25

|

10

|

75

|

|

Φ12×30×D12×75L

|

12

|

30

|

12

|

75

|

|

Φ14×45×D14×100L

|

14

|

45

|

14

|

100

|

|

Φ16×45×D16×100L

|

16

|

45

|

16

|

100

|

|

Φ20×45×D20×100L

|

20

|

45

|

20

|

100

|

|

Specification

|

Flute Dia(φ)

|

Flute Length (C)

|

Shank Dia(D)

|

Overall Length(L)

|

|

R0.5*L2*D4*50H

|

1

|

2

|

4

|

50

|

|

R0.75*L3*D4*50H

|

1.5

|

3

|

4

|

50

|

|

R1*L4*D4*50H

|

2

|

4

|

4

|

50

|

|

R1.25*L5*D4*50H

|

2.5

|

5

|

4

|

50

|

|

R1.5*L6*D4*50H

|

3

|

6

|

4

|

50

|

|

R2*L8*D4*50H

|

4

|

8

|

4

|

50

|

|

R2.5*L10*D5*50H

|

5

|

10

|

5

|

50

|

|

R3*L10*D6*50H

|

6

|

10

|

6

|

50

|

|

R4*L16*D8*60H

|

8

|

16

|

8

|

60

|

|

R5*L20*D10*75H

|

10

|

20

|

10

|

75

|

|

R6*L24*D12*75H

|

12

|

24

|

12

|

75

|

Tips:

The above specifications are standard Size, with a large amount of stock. At the same time, we support OEM customized production, the diameter is 0.2mm to 25mm, the Total length is 50mm to 200mm, include inch size end mill , the number of Flute is 4F, 5F, 6F, 8F and the logo could becustomized. (Unit: mm)

Non-standard milling cutter warehouse

Why Choose Us

Chengdu Xin'chuangjie CNC Tool Co., Ltd.

is a professional enterprise specializing in the production of high-quality carbidetools, manufacturing and sales of high-quality carbide tools.The main equipment comes from Germany, the United Statesand Switzerland.Equipment industry, automobilemanufacturing industry, petroleum industry, medical machineryand other industries provide complete cutting tool solutions.The company's main business is: carbide milling cutters,carbide drills.carbide reamers,non-standard toolcustomization, taps,CNC blades,CNC tool holders. CNC toolsand machine tool accessories,etc.

In addition to

a broad line of standard cutting tools,

Xin'chuangjie

boasts a full complement of custom tooling capabilities including an experienced team of application specialists and custom tooling designers, who provide our customers with diverse engineering capabilities. This expertise has grown organically from a combined 10-plus years of design experience. The creation of unique customer solutions can provide significant value the form of performance improvement and profitability improvement.

Vietnam Exhibition

Cambodia Exhibition

Thailand Exhibition

CERTIFICATE

SALES AND SERVICE NETWORK

TRANSPORT

FAQ

Q: Are you a manufacturer? Do you have a factory?

A:

We are professional manufacturers with more than 15 years of experience in the field of cutting tools.5 year of tungsten carbide export business. We have three sales stores in China, can provide you with one-stop shopping, meanwhile we have an excellent and professional sales team, we have strict desire on the quality of the carbide tools.

Q: Delivery time?

A: Usually the exchange time is 3-5 days after receiving the advance payment. For customized products, 15-20 days after receiving the advance payment.

Q:

How long can I expect to get the sample?

A:

fter you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays.

Q:

what can you buy from us?

A:

Carbide End Mills, Carbide Drills, Carbide Inserts, Carbide Thread Mills, Carbide Custom Tools, CNC Tool holders, CNC Cutter Heads, CNC Tools, etc.

.

Q: What's your delivery method?

A: Express, DHL, TNT, FEDEX, EMS, air and sea can be provided according to your requirements.

Q: Do you offer OEM?

A: Yes, we do.

Q: Do you produce special carbide tools?

A: We can, we can customize it according to your drawings and samples.

Q: What are your payment terms?

A: T/T30% as a down payment and 70% delivery time. Before you pay, we will show you pictures of the product and packaging.

Hot Searches