(Note: For more parameters, please contact for consultation)

- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Tool holder, pull stud, collet, milling cutter

-

Name:

-

Back-pull tool holder

-

Type:

-

BT40

-

Specification:

-

DC4 DC6 DC8 DC12

-

Texture of material:

-

High quality 20CrMnti Steel

-

Body Accuracy(Pricision):

-

≤0.002mm

-

Overall clamping Precision:

-

≤0.005mm

-

Speed:

-

G2.5 25000~30000RPM/r

-

True roundness:

-

0.8 mm

-

Carburizing depth:

-

0.8mm

-

Surface roughness:

-

0.8mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Weight (KG):

-

1.85

-

Brand Name:

-

MAIAM

-

Core Components:

-

Tool holder, pull stud, collet, milling cutter

-

Name:

-

Back-pull tool holder

-

Type:

-

BT40

-

Specification:

-

DC4 DC6 DC8 DC12

-

Texture of material:

-

High quality 20CrMnti Steel

-

Body Accuracy(Pricision):

-

≤0.002mm

-

Overall clamping Precision:

-

≤0.005mm

-

Speed:

-

G2.5 25000~30000RPM/r

-

True roundness:

-

0.8 mm

-

Carburizing depth:

-

0.8mm

-

Surface roughness:

-

0.8mm

Products Description

Product Info:

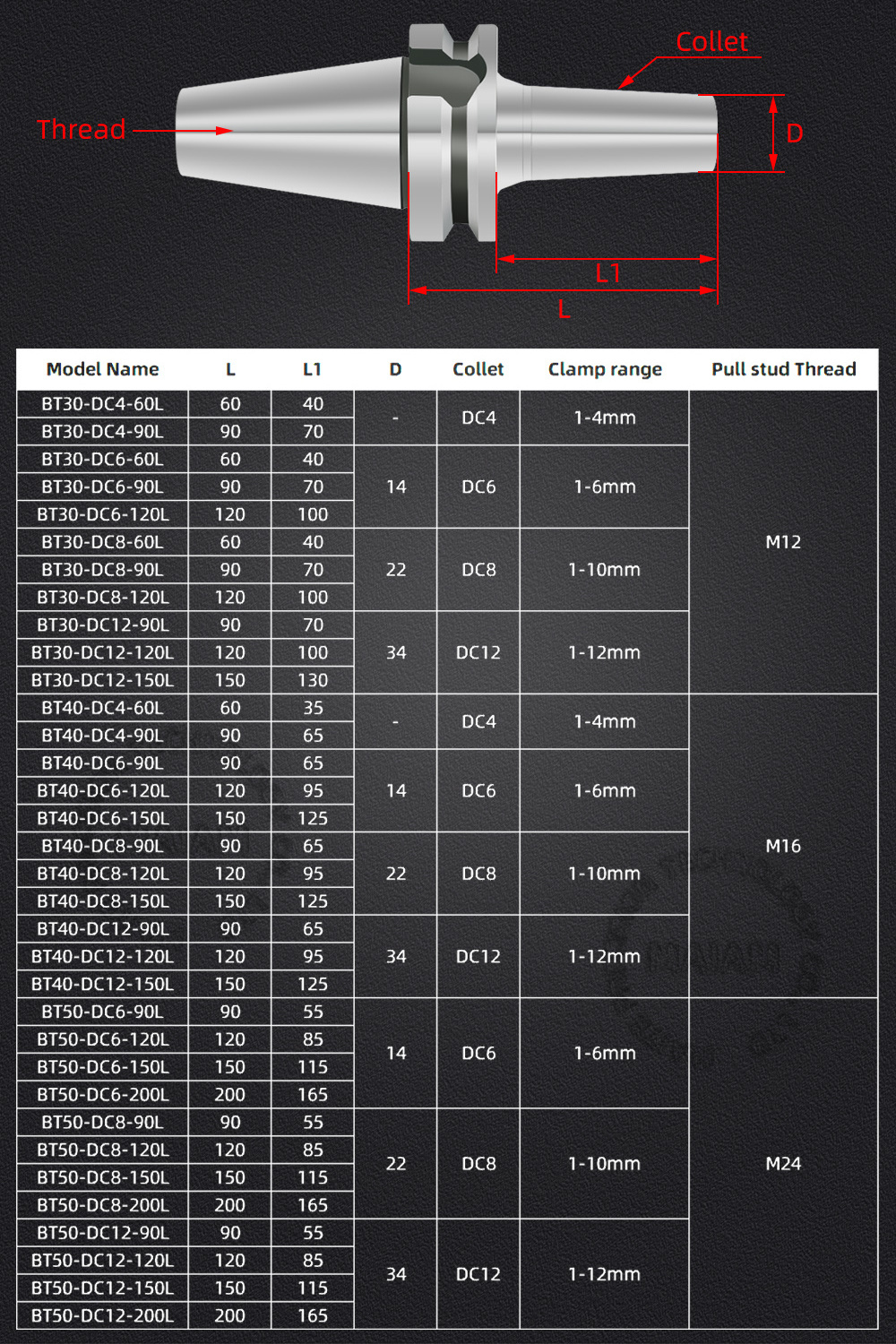

Name

:

Back-pull tool holder

Type:

BT40

Specification:

DC4 DC6 DC8 DC12

Texture of material:

High quality 20CrMnti Steel

Body Accuracy(Pricision):

≤

0.002mm

Overall clamping Precision:

≤0.005mm

Speed:

G2.5 25000~30000RPM/r

True roundness:

0.8 mm

Carburizing depth:

0.8mm

Surface roughness:

0.8mm

Function:

High-precision, high-speed, rear-pulling tool holder can be used quickly without nuts.

Application environment:

Machining, CNC machine tool, etc...

Product Paramenters

This dimension drawing is manual measurement, so there may be errors. I hope to get your understanding.

If the size deviation is too large, it is usually marked incorrectly.

(Note: Please contact for more models)

Details Images

BT30 BT40 BT50 back-pulling tool handle DC4 DC6 DC8 DC12 back-pulling collet CNC machining center engraving machine spindle tool rest

High precision & high speed

Body accuracy 0.002mm, dynamic balance G2.5 25000~30000RPM.

Through the dynamic balance test, we pursue high-precision and high-speed tool balance, adapt to high-speed cutting processing, and extend the service life.

Small diameter design, deep hole processing

The small diameter design of the front end reduces interference and vibration, ensuring more stable high-speed machining and more stable deep cavity machining.

Built-in design, fast work

The built-in design simplifies the installation, eliminates the need for nuts, reduces accidental interference in the

processing process, and is more suitable for high-speed processing.

Stable performance, more durable

The taper angle of the inner hole is designed to facilitate the loosening and holding force of the tool, and improve the stability.

Installation Instructions

This product needs to be matched with:

1. pull stud (used to connect with the main shaft of the machine)

2. collet (used to clamp the tool in the tool holder)

3. Milling cutter (clamp and fix with collet)

For more installation steps, please refer to the example in picture ① ② ③ ④ for clamping and disassembling.

Product packaging

There are many models and specifications, and the display is limited.

Different types of products have different packaging, which can be used as packaging reference.

If the quantity you need is large, we can design the package you need according to your requirements.

Hot Searches