- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Plastic Mould 0001

-

Product name:

-

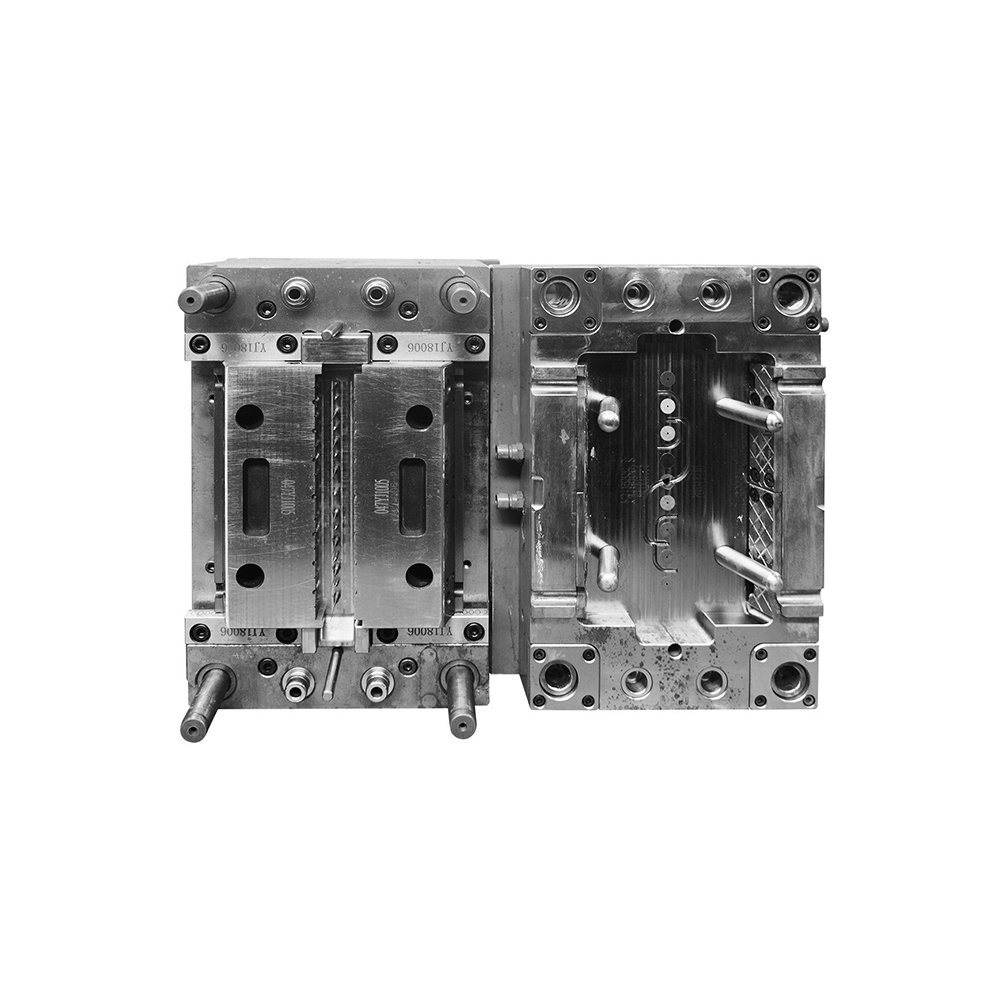

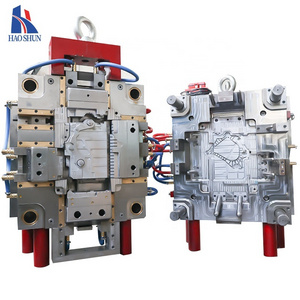

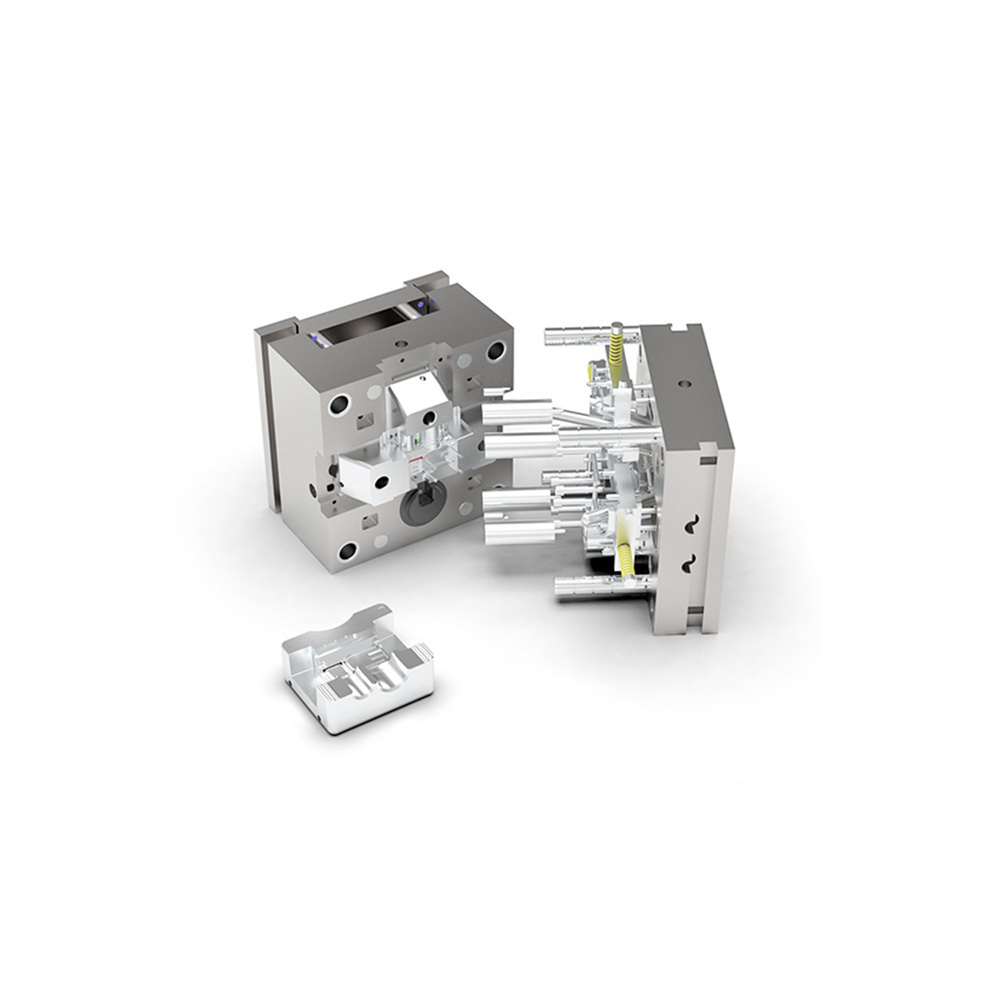

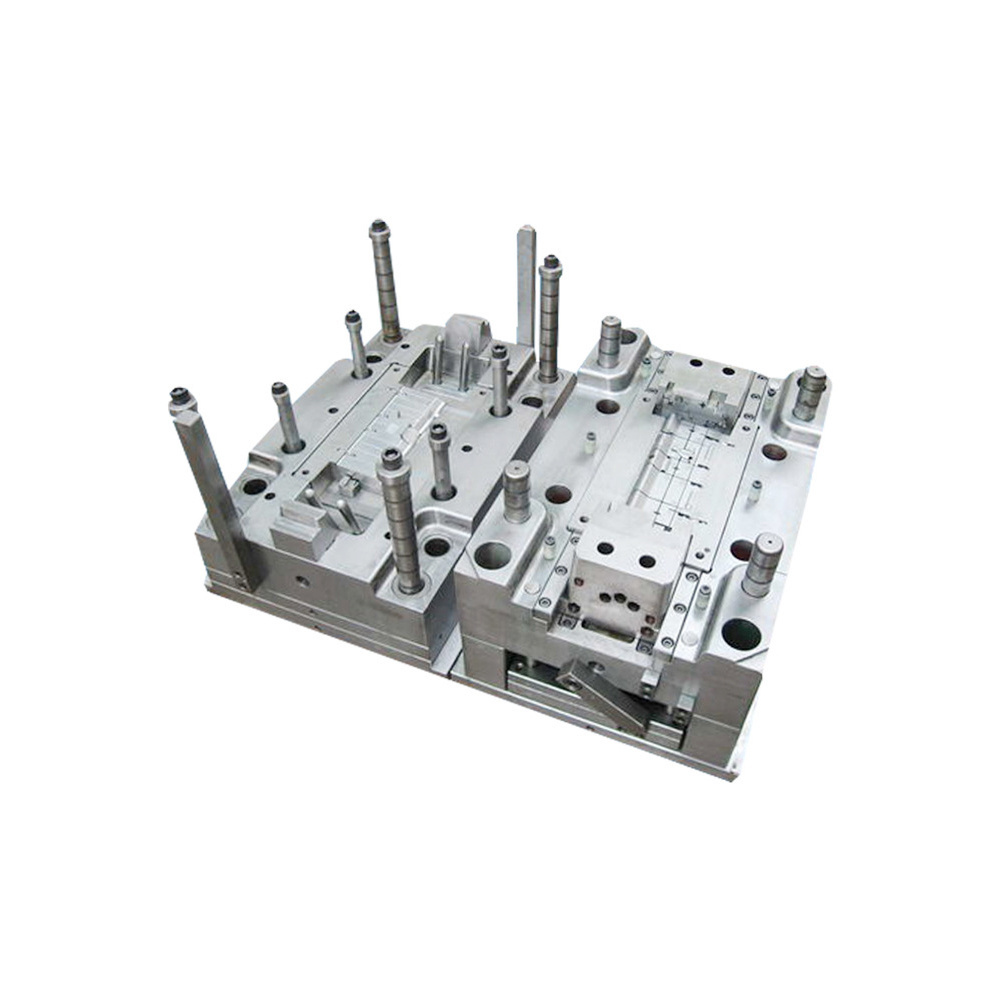

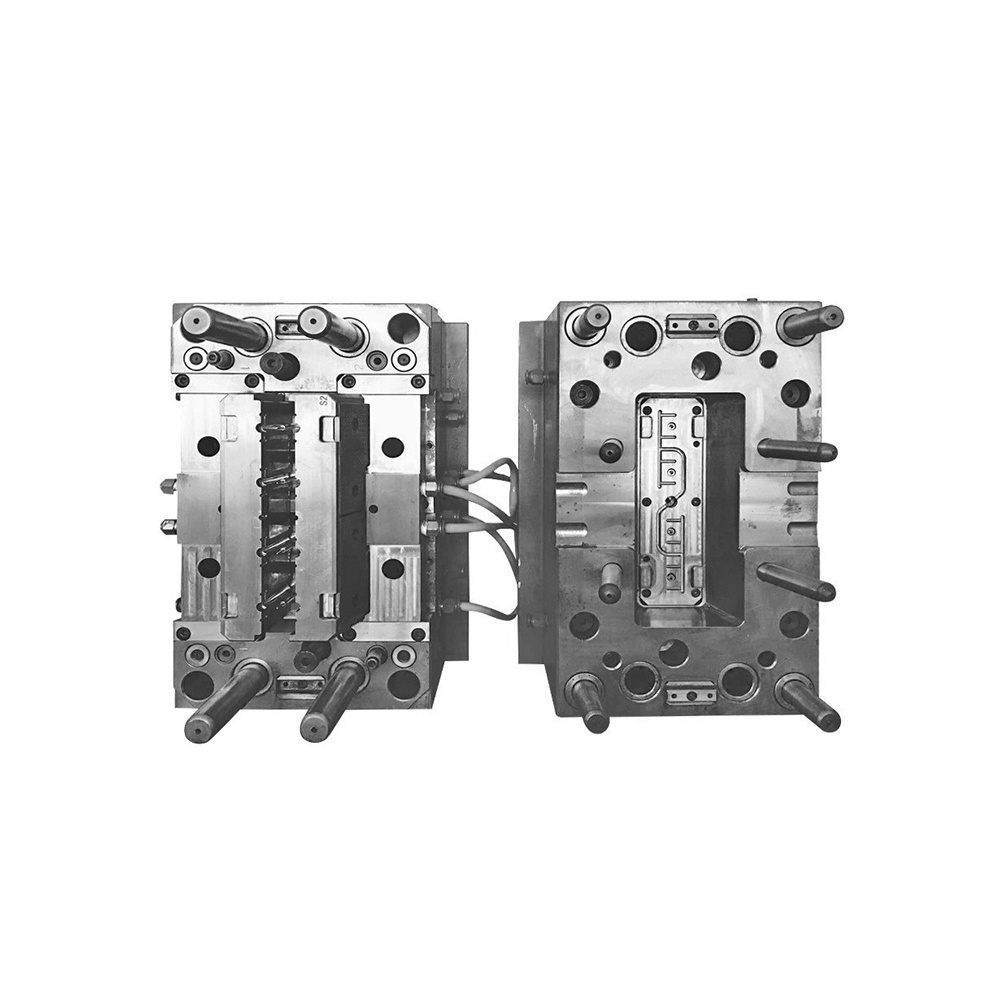

Plastic Injection Mold

-

Plastic parts material:

-

ABS,PVC,PP,PE,PMMA, Arcylic, Nylon, etc.

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Surface treatment:

-

0.02mm -0.05mm

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Base Material:

-

FR4/ROGERS/Aluminum/High TG

-

Service:

-

One-stop Service

-

Certification:

-

ISO9001/TS16949/QS/ISO14001

-

Application:

-

Vehicle Mould,Household Appliance,Household Product

-

Mould Life:

-

300000-500000 Shots

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

California, United States

-

Brand Name:

-

IBE

-

Model Number:

-

Plastic Mould 0001

-

Product name:

-

Plastic Injection Mold

-

Plastic parts material:

-

ABS,PVC,PP,PE,PMMA, Arcylic, Nylon, etc.

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Surface treatment:

-

0.02mm -0.05mm

-

Drawing Format:

-

STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other

-

Base Material:

-

FR4/ROGERS/Aluminum/High TG

-

Service:

-

One-stop Service

-

Certification:

-

ISO9001/TS16949/QS/ISO14001

-

Application:

-

Vehicle Mould,Household Appliance,Household Product

-

Mould Life:

-

300000-500000 Shots

Specification

Factory Custom Molds Maker Plastic Molding Injection Machines Moulds Hot Steel PVC Surface Software Design Mould

|

Main Product

|

Product Design,Plastic Injection Mold,Medical Parts Mold,IML/IMD,2K Injection Mold,Silicone Mold,Die Casting

Mold,Prototype,Machining Services |

|

Plastic Material

|

HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc

|

|

Mould Precision

|

+/-0.01mm

|

|

Mould Life

|

50-500K shots

|

|

Mould Cavity

|

Single cavity, multi-cavity

|

|

Runner System

|

Hot runner and cold runner

|

|

Equipment

|

CNC, EDM, cutting off machine,plastic machinery etc

|

|

Color

|

White, black, red, blue..et. according to customer's requirement

|

|

Surface Treatment

|

Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture,

Sanblasting,Gilding, UV Painting |

|

Injection machies equipments

|

According to product precision to choice the different model

80T,120T,250T,450T,800T injection machine |

|

Inspection

|

100% inspection by QC, QA before shipping

|

|

Applications

|

All kinds of cars spare part , machinery, home appliance, electronic products, medical devices, stationery, computers, power

switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts,and more. |

|

File Format

|

Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

|

|

Certificate

|

ISO9001,ISO14001,ISO13485,CE

|

Product Description

We can offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and

shipping arrangement.

Hot Searches