- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

REACH

Quick Details

-

Size:

-

Large

-

Type:

-

Single-Span Agricultural Greenhouses

-

Place of Origin:

-

China

-

Brand Name:

-

REACH

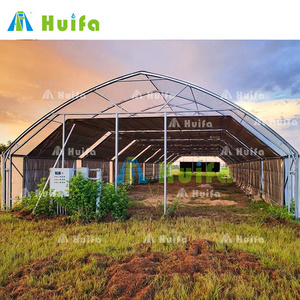

Automated Blackout Light Deprivation Greenhouse

Commercial gutter connect automated blackout shade greenhouse for medical plants culture

Product Description

Blackout light deprivation system greenhouse is used for the plants which need the extremely light requirement. It can be

automatically open and close. The fully automated light deprivation system that ensures complete control of the light cycle, also

provide valuable energy-efficient and labor-saving features.

automatically open and close. The fully automated light deprivation system that ensures complete control of the light cycle, also

provide valuable energy-efficient and labor-saving features.

The blackout greenhouse uses the three-layer blackout curtain and automated moving transmission system.

For the blackout curtain, ,two layers is black and one layer is aluminum foil. The shading rate 100%.

The light is reflected by the aluminum foil on the surface. During the light-dark period, unwanted light accumulation can be

prevented.

Screens are movable, so we can open or close them according to the weather conditions outside the greenhouse and the needs of the

crops. They can be installed in any type of greenhouse and weather.

The light is reflected by the aluminum foil on the surface. During the light-dark period, unwanted light accumulation can be

prevented.

Screens are movable, so we can open or close them according to the weather conditions outside the greenhouse and the needs of the

crops. They can be installed in any type of greenhouse and weather.

Why Light Deprivation?

Why Light Deprivation?

The highest quality flowers can be produced with light deprivation because you have the environmental controls of an indoor

facility but the spectrum and lumens the SUN provides. Controlling the light cycle by depping (covering) the greenhouse gives the

growers the ability to grow more dense flower by being exact with the timing of the flowering photo periods. The biggest advantage

of our fully automated light deprivation greenhouses is the ability to get this timing exact. One forgetful grower forgetting to

pull tarps on a manual greenhouse by just a few minutes here and there can really impact the quality of the flower.

The highest quality flowers can be produced with light deprivation because you have the environmental controls of an indoor

facility but the spectrum and lumens the SUN provides. Controlling the light cycle by depping (covering) the greenhouse gives the

growers the ability to grow more dense flower by being exact with the timing of the flowering photo periods. The biggest advantage

of our fully automated light deprivation greenhouses is the ability to get this timing exact. One forgetful grower forgetting to

pull tarps on a manual greenhouse by just a few minutes here and there can really impact the quality of the flower.

LED Lighting

Cannabis is a short-day, sunny plant, which requires extremely high light requirements. If the light intensity does not meet the requirements, it will affect its growth.Especially in the greenhouse or in the basement planting, affected by building materials, light weakened or even completely no light, for the growth of marijuana and flower bud differentiation has a great impact, so to fill the marijuana in time.

Because industrial hemp has high requirements for light intensity, so when choosing the light lamp, we should pay attention to the power of the light lamp. It is best to choose the high-power LED light lamp, which can not only ensure the light intensity, but also save energy.High-power module plant light filling lamp can be combined according to the demand to meet the requirements of plants for light intensity.For example, the high-power module plant light, a 200W light flux can be 16,000 l m, used in greenhouse engineering, plant factories the most, the effect is also very good, completely suitable for industrial hemp light.

Specification

|

Name

|

Specification

|

Remark

|

|

|

|||

|

Length

|

Customized, length no much limt

|

|

|

|

|||

|

Span width

|

8m, 9m, 12m

|

|

|

|

|||

|

Width

|

Usually within 60m better

|

|

|

|

|||

|

Gutter height

|

4m

|

|

|

|

|||

|

Total height

|

4.9m/6.5m

|

|

|

|

|||

|

Wind load

|

0.5KN/m2

|

|

|

|

|||

|

Snow load

|

0.4KN/m2

|

|

|

|

|||

|

Hanging load

|

3lb/sqft (15Kg/m2)

|

|

|

|

|||

|

Standard system

|

Hot Galvanized Steel Frame/ PC board/ Blackout System/ Two ends iron sheet/ Control Box

|

|

|

|

|||

|

Optional system

|

Cooling System/ Ventilation System/ Heating System/D ehumidifier/ CO2 Generator/

Growing Light/ Rolling bench/ Fertigation system

|

|

|

|

|||

Blackout poly (Black on the side, White on the outside) Black/White string-reinforced polyethylene is a film that is manufactured using a mix of virgin polyethylene resins. To manufacturer this product we use a black polyethylene skin on one side and a white polyethylene skin on the other. The black side completely contains light, the white side reflects heat. The skins encapsulate a grid pattern of polyester yarn, and a hot sheet of polyethylene, to form a very strong three layer productappropriate for multiple applications. 3-5year rated film.

Packing & Delivery

Dear clients,

various package to guarantee the safty of your goods (like b

undle, bag, carton, pallet, polywood box etc)

And all cargo we mark with label coding.

Details as below:

1. All the steel material is nude packing.

2. Motor and electric machines are put in carton.

3. Small steel parts are put in bag.

4. Glass is put in iron frame.

5. All the material is put in containers.

3. Small steel parts are put in bag.

4. Glass is put in iron frame.

5. All the material is put in containers.

Any need pls send inquiry to me

Ms. Teresa (teresa at sinoreachgroup.com)

Hot Searches