- Product Details

- {{item.text}}

Quick Details

-

Specification:

-

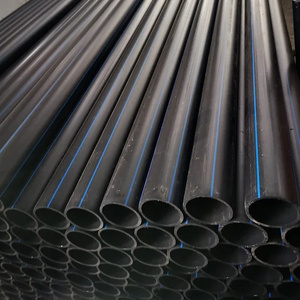

16-1000mm or as request

-

Length:

-

3m,5.8m,11.9m, or customized

-

Thickness:

-

2.0 to 90mm

-

Standard:

-

Standard, ISO9001

-

Product Name:

-

Marine and Dredging Industry Slurry Dredging UHMWPE Pipes

-

Desinity:

-

0.95g/cm3

-

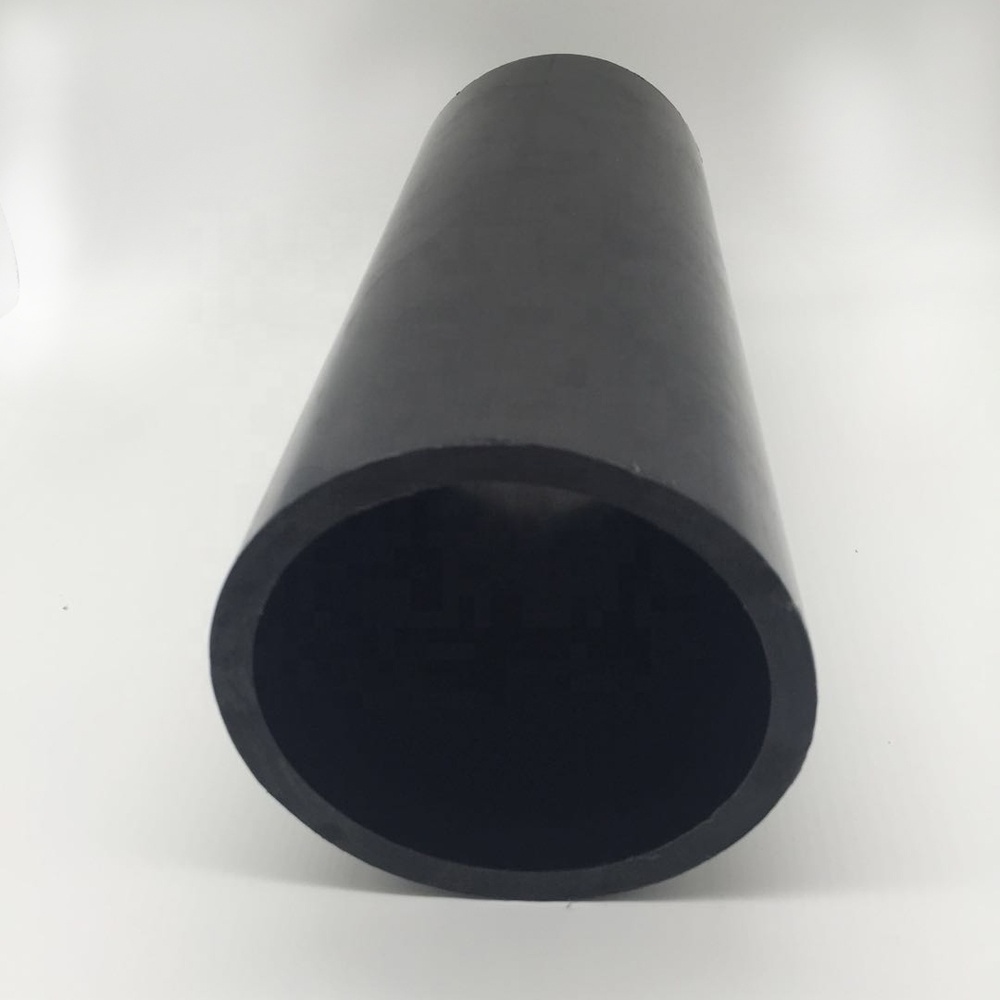

Color:

-

black , white, can be customized

-

Surface:

-

smooth, no spot

-

Craft:

-

extruded

-

OEM:

-

yes

-

MOQ:

-

50m

-

Delievery time:

-

8 working days

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Erikeke

-

Model Number:

-

EKK2004

-

Specification:

-

16-1000mm or as request

-

Length:

-

3m,5.8m,11.9m, or customized

-

Thickness:

-

2.0 to 90mm

-

Standard:

-

Standard, ISO9001

-

Product Name:

-

Marine and Dredging Industry Slurry Dredging UHMWPE Pipes

-

Desinity:

-

0.95g/cm3

-

Color:

-

black , white, can be customized

-

Surface:

-

smooth, no spot

-

Craft:

-

extruded

-

OEM:

-

yes

-

MOQ:

-

50m

-

Delievery time:

-

8 working days

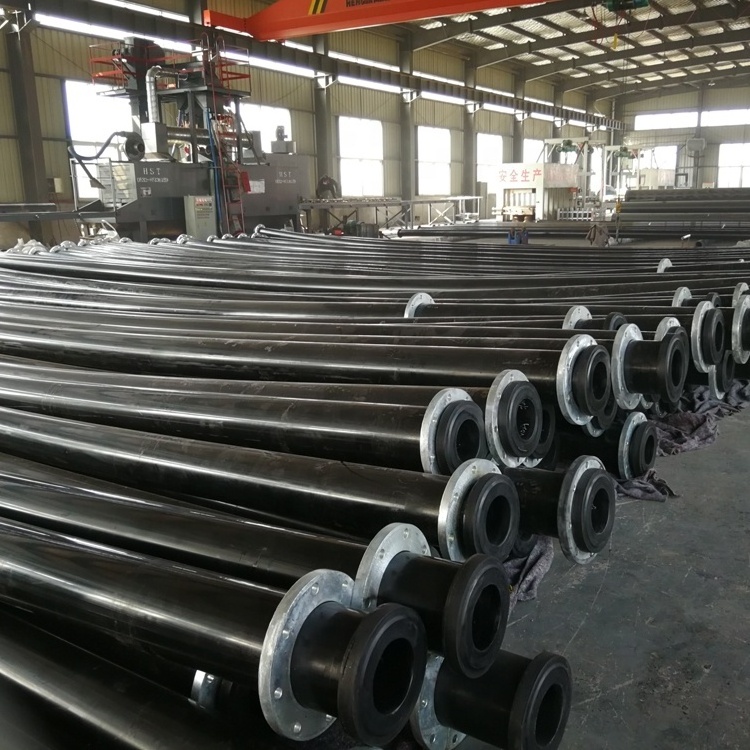

Sand Dredging Pipelines Petroleum Transport UHMWPE Pipes

The Features of UHMWPE Pipe

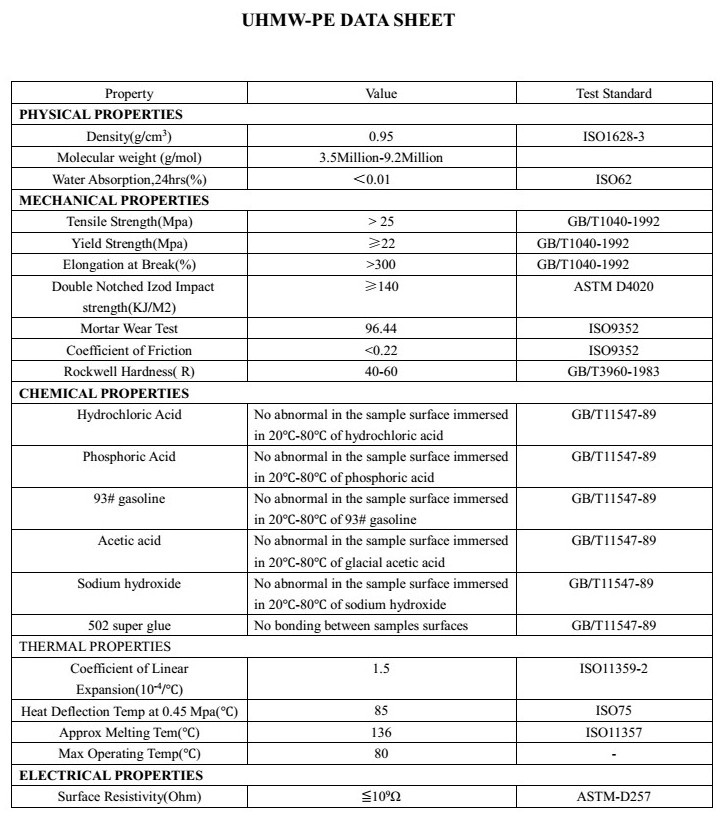

UHMWPE(Ultra high Molecular Weight Polyethylene) is a thermoplastic engineering plastic with the average molecular weight more than 9.2 million (100% Virgin UHMW-PE Raw Material) . This kind of material with five top performance of high-wear-resistance, good-chemical resistance, low-temperature resistance, self-lubrication and high-impact resistance, which is regarded as a “surprised” engineering plastic of excellent comprehensive capacity and competitive price.

The wear resistance of UHMWPE pipes is 4~6 times higher than Q235 carbon steel, 2.7 times higher than silicon-manganese 13 wear resistant steel, 3 times higher than HDPE pipes, which enables UHMWPE pipes to be ideal for sand and slurry discharging.

UHMWPE Pipe Advantages

1. Wear Resistance : the abrasion value of UHMWPE pipe is 1/7 of steel pipe, 1/3 of HDPE pipe under same working conditions.

2. Water hammer resistance : UHMWPE pipes have strong enduring capability to the impacts from various sands, mud and slurries.

3. Corrosive resistance : Higher structure stability, corrosion resistant to various chemical mediators. No electrochemical corrosion, no need anti-corrosive coating.

4. Self-lubrication: The roughness of UHMWPE is 0.00022mm. The pressure loss of UHMWPE pipe is 1/10 of steel pipes, 1/7 of nylon pipes. Over 20% of transfer efficiency will be increased.

5. Non-scaling : the internal wall is very smooth, preventing the fouling on the wall and no influence to the production efficiency.

6. Light weight : the density of UHMWPE pipe is only 1/8 of steel pipe. It is easy to move and install, especially suitable for the working sites at where the lifting machines could not work.

7. Easy connection : flanges are available to connect the pipes, no need washers. The installation will be very easy and fast. There are no dangers and concerns of water leakage.

8. Anti-aging : the UHMWPE pipes will not be aging in 50 years under hot sunlight, and it could work over 100 years if buried underground.

9. Environment friendly : UHMWPE pipe is nontoxic, no bacteria, and no pollution to environment.

10. Low carbon : the discharge of carbon dioxide during UHMWPE pipe production is only 15% of steel pipe production, which is good for environment protection.

11. Temperature Resistance : UHMWPE pipes could be used under the temperature of -70ºC-80ºC, and there is no deformation.

12. Long working life : the working life of UHMWPE pipe is 7 times longer than steel pipe and 3 times longer than HDPE pipe under same working condition

UHMWPE Pipe Applications

1. Mine & Metallurgy industry

: Coal/Ore/Nonferrous metal mine tailings, slurry and rock delivery

2. Food industry

: grain & flour transport

3. Dredge

: slurry & sand dredging

4. Chemical industry

: mud and corrosive medium with slag

5. Water Disposal

6. Coal industry

: pulverized coal waste and coal-water slurry

7. Sea & River engineering

: sea water desalinization, dredging

8. Oil & Gas, petroleum transport

| 1. Are you manufacture? | YES, we are manufacture. |

| 2. Do you provide free sample? | YES, we supply you free sample within one day. |

| 3. What is your deivery time? | Our delivery time is normally 7 to 15 days after deposit received. |

| 4. What is the payment terms? | *T/T, 30 of deposit, balance paid refer to copy BL. |

| *L/C at sight | |

| *West union |