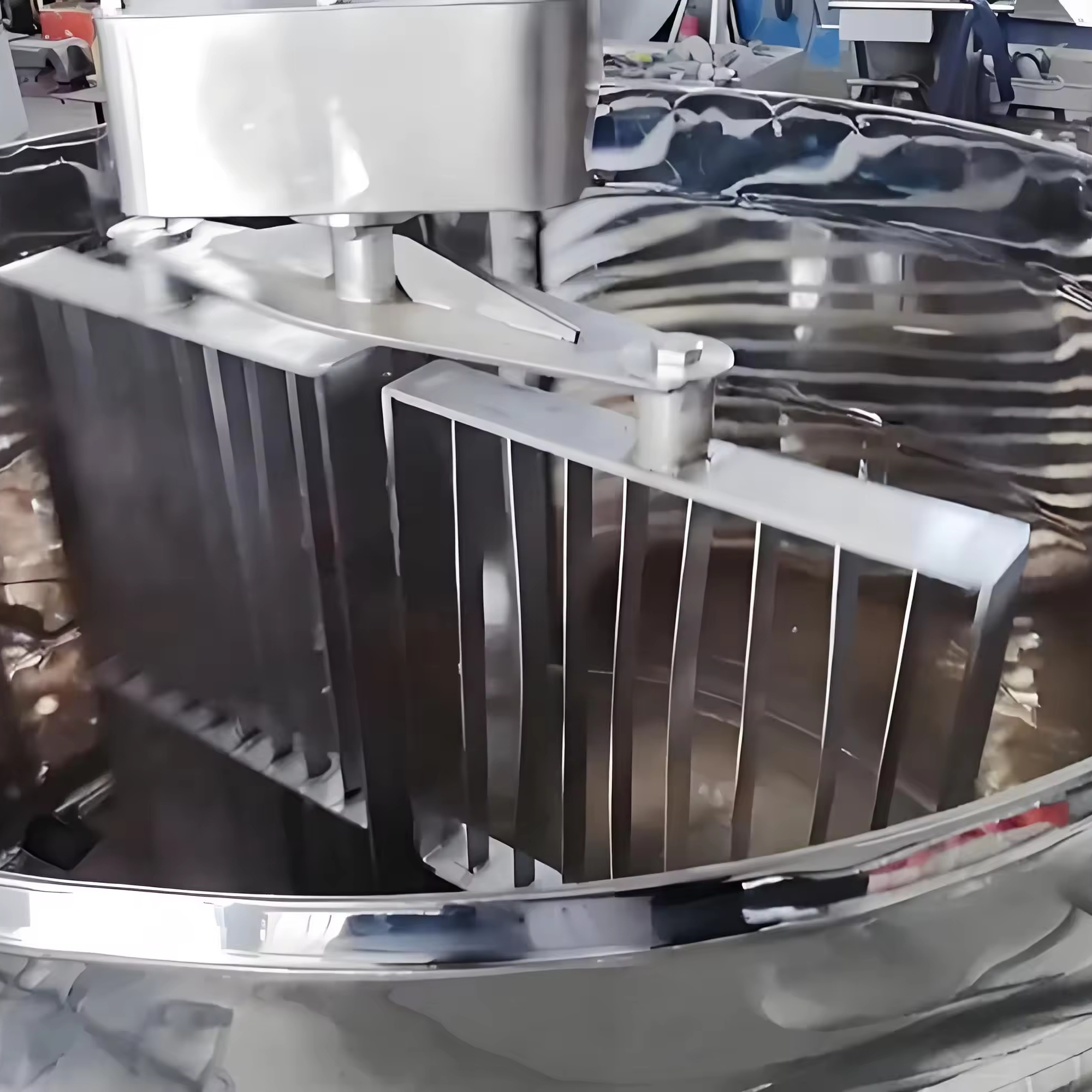

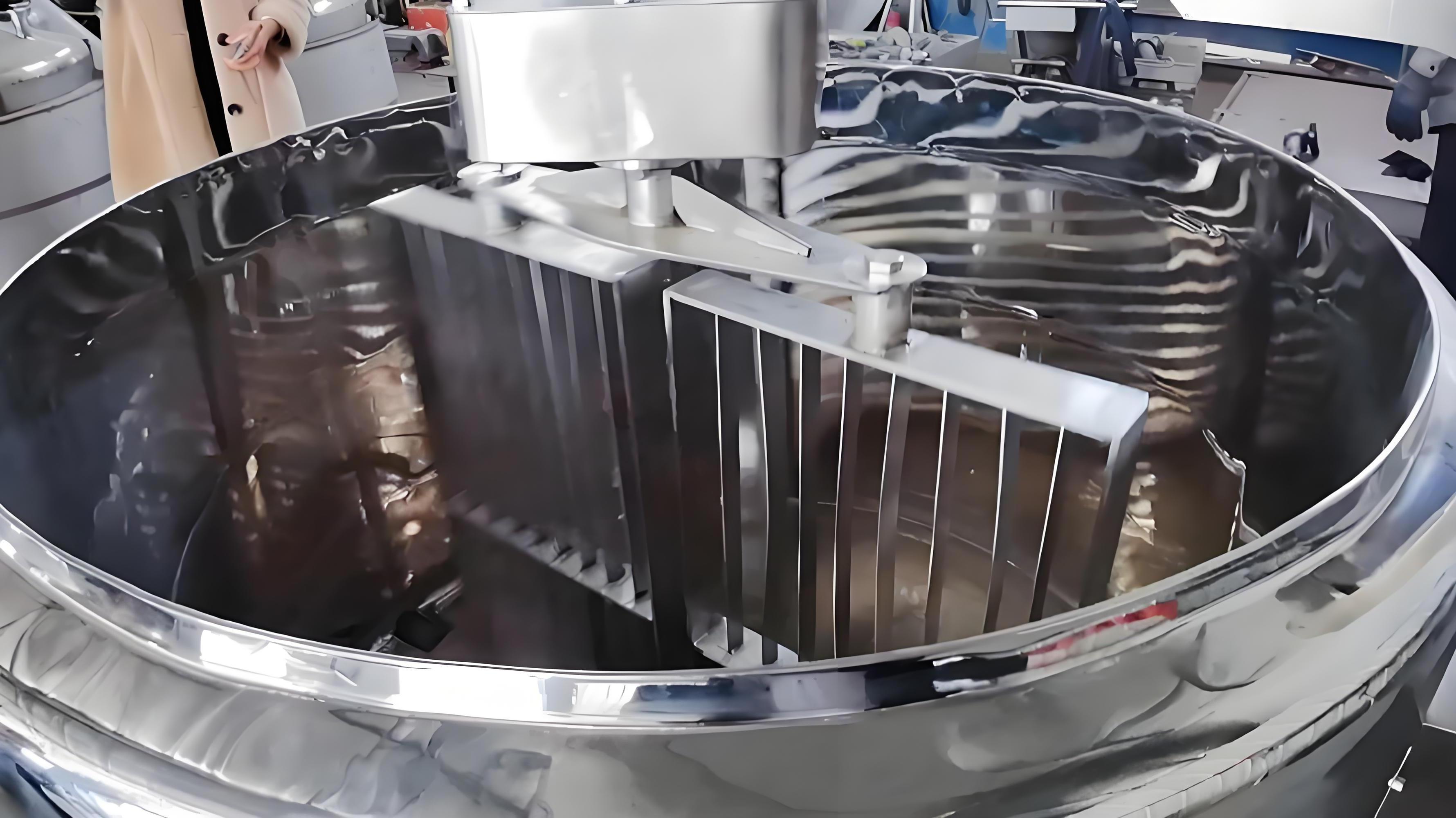

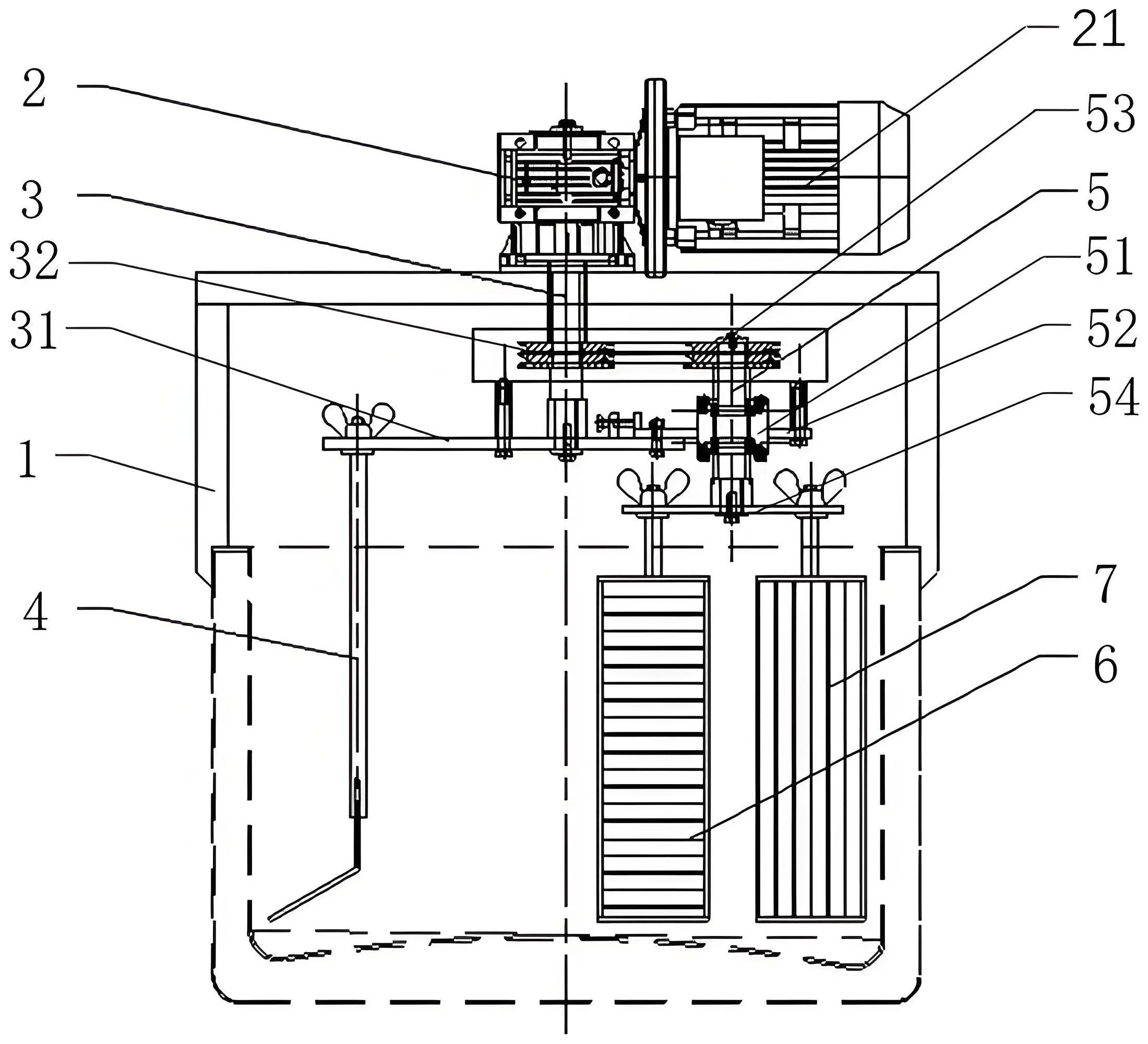

dry cheese vat is used the cutter agitator to cut the semi-solid cheese into small size pieces and remove inside water of cheese ,

and left the small size cheese ,and dry it into the cheese dry cheese vat strcture as below : 1).Sanitary Stainless steel 304 or

316L 2).single layer or jacketed type 3) With rotary CIP spray ball to wash inside vessel surface 4)the capacity can be made from

50L to 20000L 5)tank equipped with fittings of top lid cover ,agitator system and outlet system and inclined system

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

150 KG

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Beijing, China

-

Voltage:

-

380V 50HZ

-

Weight:

-

150 KG

Product Description:

Cheese Vat is composed of main body, motor, mixing and cutting agitators, control box, etc. It can used for mixing ingredients,milk solidification, whey cutting, heating and cooling. The cheese milk is pretreated, after addition of a bacteria culture appropriate to the type of cheese, and mixed with rennet. The enzyme activity of the rennet causes the milk to coagulate to a solid gel known as coagulum. This is cut with special cutting tools into small cubes of the desired size to facilitate expulsion of whey. During the rest of the curd making process the bacteria grow and form lactic acid, and the curd grains are subjected to mechanical treatment with stirring tools, while at the same time the curd is heated according to a preset program. The combined effect of these three actions – growth of bacteria, mechanical treatment and heat treatment – results in syneresis, i.e.separation of whey from the curd grains. The finished curd is placed in cheese moulds, which determine the shape of the finished cheese. The cheese is pressed, either by its own weight or by applying pressure to the moulds. Finally, the cheese is coated,wrapped or packed. Most kinds of cheese will ripened in the ripening room for deferent period.

|

Product name

|

Cheese Vat

|

|

Material

|

SS304/ SS316/SS316L

|

|

Mixer Type

|

cutter Agitator

|

|

Heating type

|

steam ,electrical or hot water

|

Function introduction:

Dear Customer:

We specialize in stainless steel stirring tank, fermenter, extraction tank, cheese vat, colloid mill, emulsion tank,

pasteurization machine, ultra-high temperature sterilization machine, milk cooling tank, spray sterilization machine

all kinds of beverage production line, yogurt production line. All capacities can be customized, looking forward to your inquiry!

Our company's customer service tenet is: "The customer always comes first."

From the perspective of management, first of all, we have cultivated a positive sense of service. Second, we have established a first-class customer service system and system framework, optimized the entire service process, and improved our service level. Third, we manage customer satisfaction and loyalty; Fourth, improve the ability of customer service personnel; Fifth, we properly handle customer complaints with optimism and do our best to make customers satisfied.We consider every need of customers from all aspects and serve customers with the most professional ability.

FAQ

1 ) Q: How can we visit your factory?

A: If you come from abroad, air to Beijing airport, then we can pick you up at airport.

2) Q: How do you ensure the quality of your products?

A: Our Company is a state owned enterprise with more than 16 years experience , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.

3) Q: What payment methods your company accept?

A: We accept most of the payment methods , but mainly accept T/T, L/C at sight .

4) Q: How long is the warranty time for your products?

A: Our officially promised warranty time is 12 months after commissioning .

5) Q: I am new in this field,can you supply us turnkey services?

A: YES.We can supply all the system including Market Analysis/Product Analysis/Location Choice/Processing Flow Design/Equipment Layout Design/Building Design direction/Equipment mode selection/Equipment Manufacturing/Equipment Mounting/Equipment Debugging/Worker Training.

Hot Searches