- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

hongfa

-

Voltage:

-

380

-

Dimension(L*W*H):

-

3000*1500*3000

-

Weight (KG):

-

10000 kg

Quick Details

-

Type:

-

Paving Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

Other, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3200 pcs/8hours

-

Brick size:

-

400*100*200 mm, 240*115*90 mm, 230*220*115 mm

-

Place of Origin:

-

China

-

Brand Name:

-

hongfa

-

Voltage:

-

380

-

Dimension(L*W*H):

-

3000*1500*3000

-

Weight (KG):

-

10000 kg

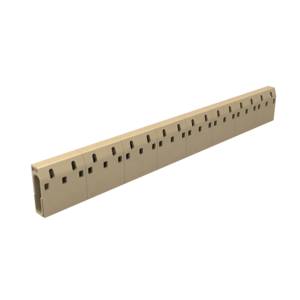

Black Basalt Granite Kerb Stone / Patio stone granite making machine

|

|

|

|

HFT650 All-in-one machine for curbstone and Terrazzo tile slab pressing color stone marble tile making machine Terrazzo tile polisher, HFT650 terrazzo tile slab making machine 1200*620 mm terrazzo floor tile press machine for sale cement tiles colored stone slab cement curbstone block making machine road edge granite step stone making machine

HFT650 Terrazzo tile machine,curbstone machine,tile slab machine Features

-The molding process uses a high-pressure filter press molding process, which can comprehensively improve product quality and strength while ensuring rapid production;

-The equipment is fully controlled by PLC computer, which can control all the actions of the equipment, oil circuit and gas circuit system through the computer, reducing labor costs and improving production efficiency;

- Lifting mold frame, without changing the mold, by adjusting the limit of the frame, it can produce curb stone products with different thicknesses;

-The main cylinder, base, guide column and other frame parts of the main engine are all made of integral castings, which can greatly extend the life of the main engine. Under natural circumstances, the castings can be guaranteed for 20 years.

Description of molding process

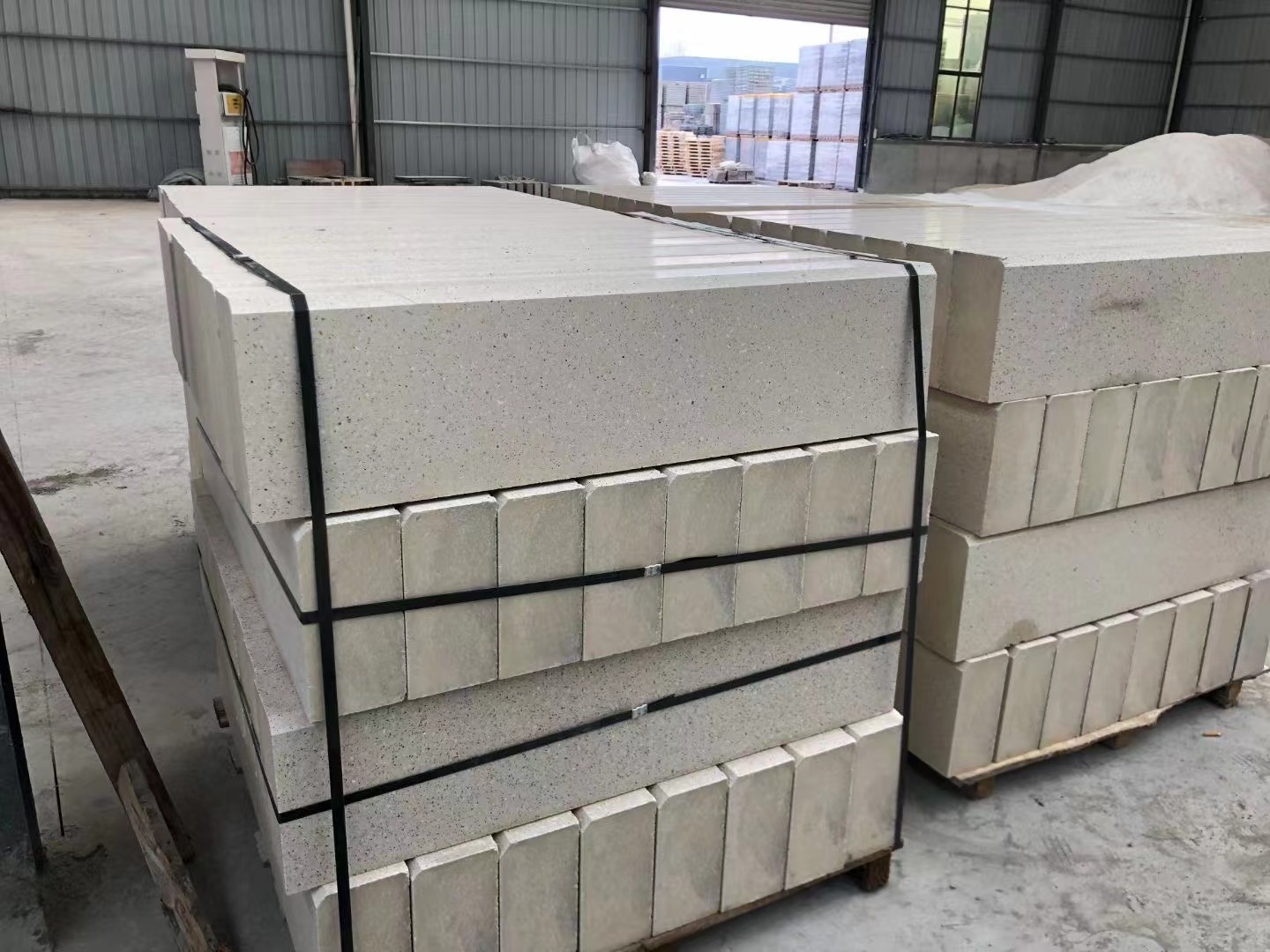

- HFT650 concrete slab making machine, the forming process adopted is a forming process used to form the concrete slurry by high pressure pressing. It is characterized in that during the pressing process, the water in the slurry can be squeezed out so that the green body can be quickly formed and demoulded, and in the process of squeezing out the water, the concrete slurry is locked so that it will not be lost together with the water. To preserve the strength of the finished product.

Advantages

The advantage of this process is that it can be pressed with wet concrete slurry, the finished product has less air holes, and has a relatively good degree of bonding between cement and sand; at the same time, it has a looser ratio in moisture control than dry hardness. (15%-20%, dry hardness 6%-8%); at the same time, no vibration is involved in the molding process, so the noise is relatively small during mechanical operation.

| Technical Parameters | |

|

Production capacity

|

700m2 /8hours |

|

Preset pressure

|

500 ton |

|

Forming method

|

Hydraulic press |

|

Switchboard power

|

30KW

|

|

Product specification

|

1000*200-500*100-200mm

|

|

Dimensions

|

4000*2000*2650mm

|

|

Host machine weight

|

13000KG |

|

Labor capacity

|

4-5 wokers/shift |

Mold Features

- The mold is a combined structure of mold core, frame, liner and socket, which is easy to repair and replace

- The main part of the mold is made of integral pouring material, and the mold has a long service life

- The upper head and the lower mold core are equipped with drainage holes and auxiliary drainage grooves, which are convenient for quickly filtering out water during the molding process

- The indenter and core are equipped with a detachable filter layer for filtering mud, which is easy to disassemble, wash and replace.

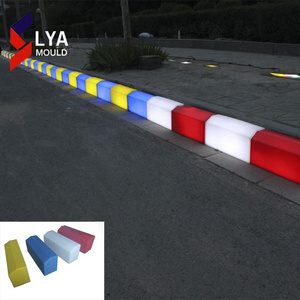

Finished products

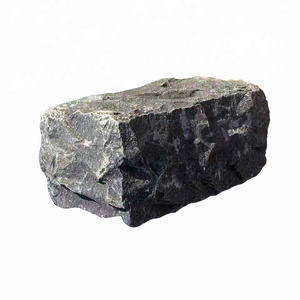

Raw materials

Polishing machine

Similar Products

|

HFT300 Terrazzo tile making machine1) Special designed for manual operation,low investment, high efficiency

2) Two molds at both sides, can produce terrazzo tiles at the same time 3) Hydraulic pressure guarantees the high density of the terrazzo tile 4) The tile machine easy operation,low maintenance rate 5) HFT300 terrazzo tile machine can produce floor tile,pave brick,paving tile,garden tile, with customized pattern 6) The machine can install with Pan mixers 7) Only three or four workers can run the terrazzo tile molding machine |

Artificial quartz stone slab making machineEngineered quartz (not to be confused with Quartzite, another appealing natural stoneused as counters) is a manmade product created mostly from natural materials. It's made of 90 to 94 percent ground quartz and 6 to 10 percent resins and pigments that are combined into durable and nonporous slabs.

Application of artificial quartz stone and engineered quartz plate

[1]For engineered marbles the most common application is indoor flooring and walls, while the quartz based product is used primarily for kitchen countertops [2] As an alternative to laminate or granite. [3] Related materials include geopolymers and cast stone. Unlike terrazzo, the material is factory made in either blocks or slabs, cut and polished by fabricators, and assembled at the worksite. |

|

|

|

Full-automatic cement color roof tile making machine

1. Quick molding speed, high output, reliable performance. Adopting PLC automatic control. man-machine interface makes performance more reliable and more convenient. The molding speed can reach 8 pcs/min, with full hydraulic and pneumatic production.

|

HFT650 Cement Tile Making Machinery Road tile terrazzo tile making machine all in-one machine kerbstone curbstone making machine porcelain glazed ceramic tile making machine marble in house floor tiles making machine Terrazzo Floor Tiles Making Machine ceramic making machine paver tiles making machine ceramic tile floor cleaning machine clay roof tiles making machines terrazzo tile making machine PC slab making machine ceramic porcelain floor tile making machine 8mm wall tile making machine máquina para fabricar baldosas de porcelana cerámica auto PC slab making machine precast concrete tile slab making machine concrete floor tile making machine baldosa de concreto Bespoke Anti-Slip Terrazzo Pavers Tiles for Public Floor Use precast concrete kerbstone making machine cement curbstone making machine for pavement edge stone making machinery price