- Product Details

- {{item.text}}

Quick Details

-

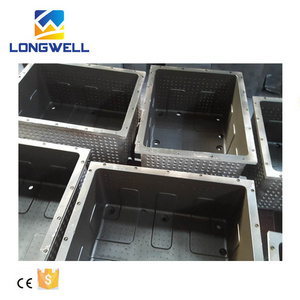

Product Name:

-

EPS(Styrofoam) mold,EPO mold,EPP mold

-

Mould material:

-

Aluminum alloy 6061

-

Surface treatment:

-

Teflon coating

-

Application:

-

Home Appliance and etc.

-

Lead time:

-

15-25 days

Quick Details

-

Shaping Mode:

-

Foaming mold

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Chiko

-

Product Name:

-

EPS(Styrofoam) mold,EPO mold,EPP mold

-

Mould material:

-

Aluminum alloy 6061

-

Surface treatment:

-

Teflon coating

-

Application:

-

Home Appliance and etc.

-

Lead time:

-

15-25 days

Product Description

|

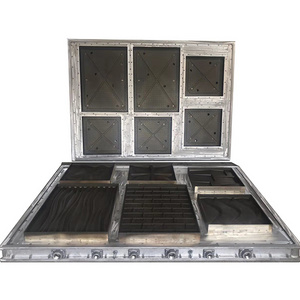

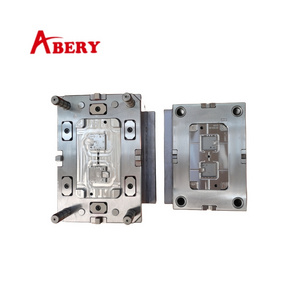

Product Name

|

Foming Mould, Aluminum mold

|

|

|

Category

|

EPS(styrofoam) mold,EPP mold,EPO mold

|

|

|

Application

|

Packing industry, Home appliance,Consumer Electronics,Toys, Furniture, Aeromodelling, Sporting and etc.

|

|

|

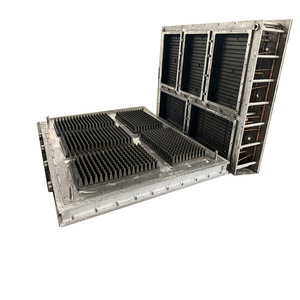

Advantage

|

|

|

|

It Reduced Weight:

|

the mould is made of Aluminum, it is much lighter than steel.

|

|

|

Strengthened:

|

The foam-like structure produced by foaming moulding makes plastic items stronger and more rigid. As a result, products may be

more durable and last longer. |

|

|

Short Lead Time:

|

only 15-20 days to finish one set of mould.

|

|

|

Improved Thermal Insulation:

|

Plastic components can improve their thermal insulation capabilities by having a foam-like structure formed by the foaming

moulding process. |

|

|

Reduced Shrinkage:

|

Gas can be added during the foaming moulding process to help minimize shrinkage, producing more accurate and exact components.

|

|

|

Cost-effectiveness:

|

This moulding can lead to cost savings since it uses less material, has a faster cycle time, and produces a better product. Due to

the decreased weight of the produced plastic pieces, it can also save shipping costs. |

|

|

Eco-friendly:

|

Foaming moulding is also environmentally friendly since it uses less material and produces less waste.

|

|

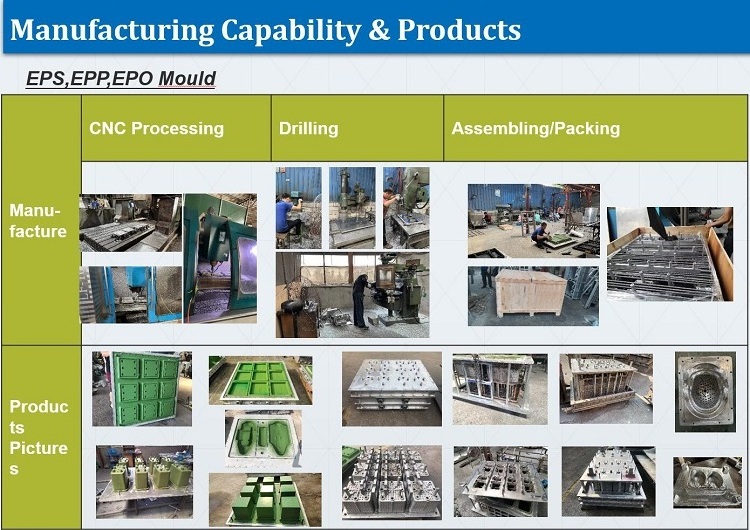

Manufacturing Technique

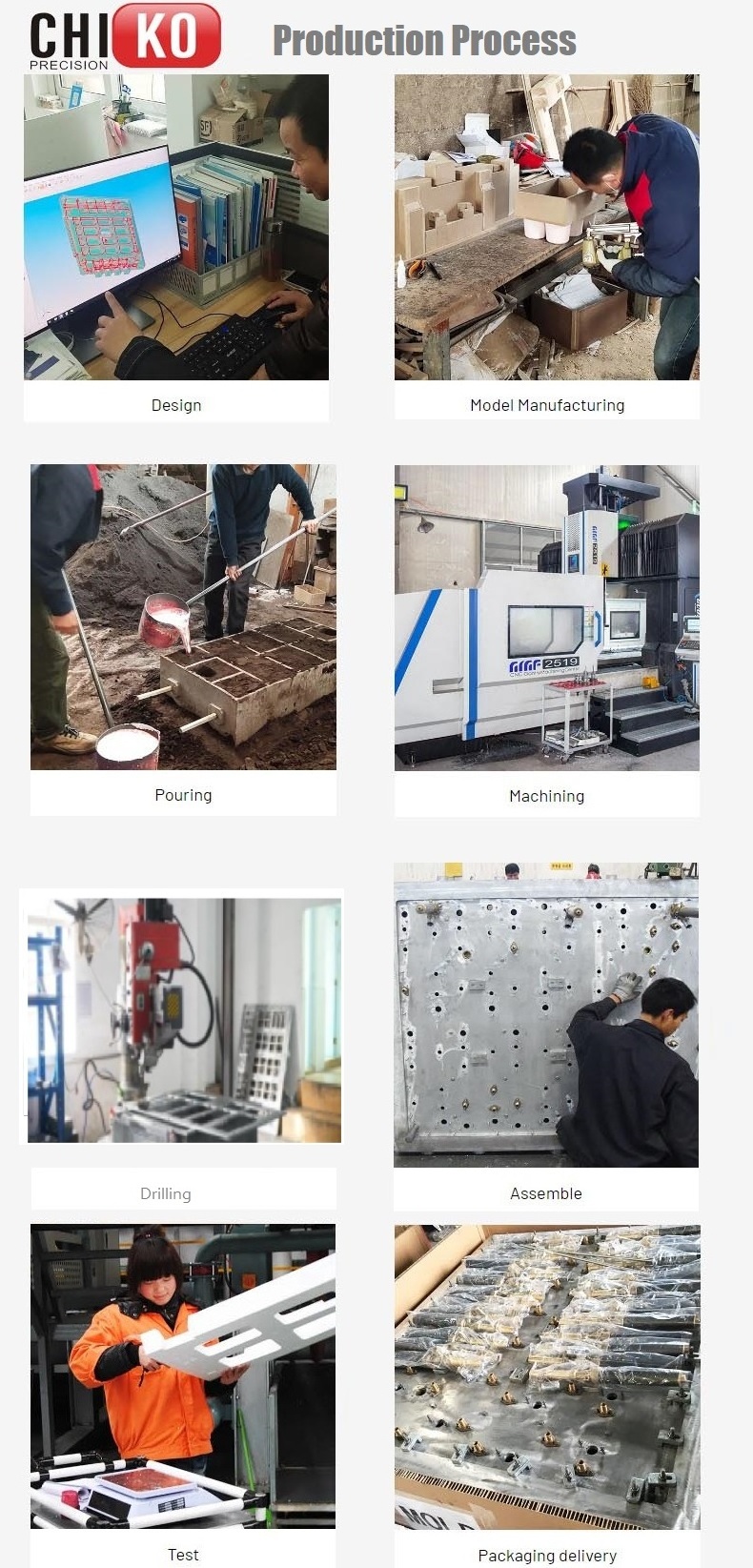

Production Process

Application

Hot Searches