- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AHC-450/540A

-

Voltage:

-

380V or 220V 3 phase

-

Power:

-

5KW

-

Dimension(L*W*H):

-

7750*2320*1660

-

Weight:

-

3 Ton

-

Warranty:

-

1 year

-

Certification:

-

CE

-

color:

-

customization

Quick Details

-

Type:

-

book case making machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kingsun

-

Model Number:

-

AHC-450/540A

-

Voltage:

-

380V or 220V 3 phase

-

Power:

-

5KW

-

Dimension(L*W*H):

-

7750*2320*1660

-

Weight:

-

3 Ton

-

Warranty:

-

1 year

-

Certification:

-

CE

-

color:

-

customization

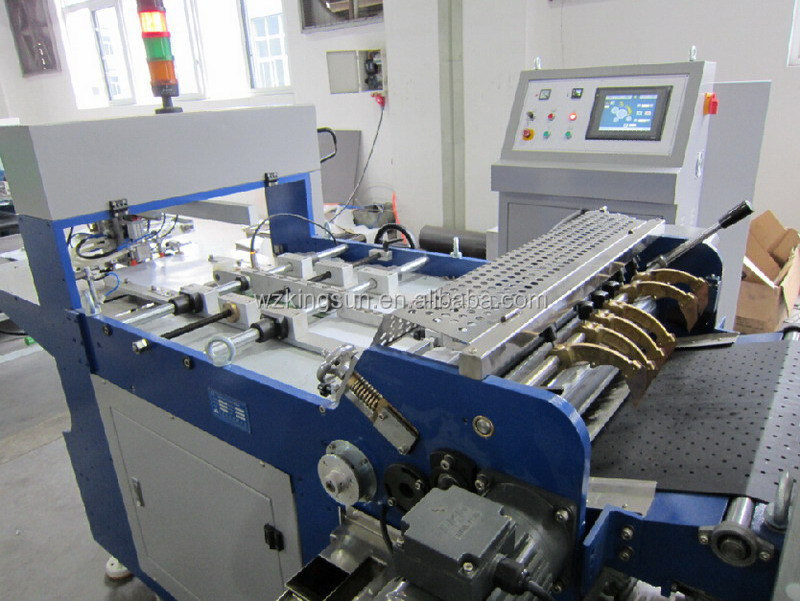

AHC-450/540 Automatic book hard cover making machine, automatic book case maker

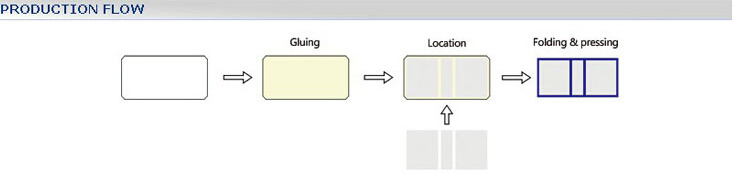

This AHC series hard cover making machine or automatic case maker adopts an automatic paper feeding system and utilizes an automatic positioning system

for the correct placement of cardboard. It is with features of high accurate and fast in producing and beautiful finishing

for making hard book covers, notebook covers, desktop or hanging calendars, lever arch file folders etc.

Features:

1.The feeder using a backpush feeding system which is controlled pneumatically, this structure is simple for operation and designed reasonably.

2.The width between stacker and feeding table is concentrically adjusted in the center; the operation is very easy and

without tolerance.

3.A newly designed, durable copper scraper effectively prevents paper winding onto the glue roller.

4.The imported ultrasonic paper detector, easy to operate, it effectively prevents paper jams or two pieces of paper feeding

at one time.

5.The cardboard feeding table is controlled by linear guide line and servo motor, its positioning is precisely and quickly.

6.Auto stop response in case of paper shortage in the cardboard feeding table.

7. .Big power air sucker is adopted for conveyor belt to feed the paper more stably and accurately.

8.Paper and cardboard feeding and positioning by use of an imported high precision photo electric control device for

accurate positioning of paper and cardboard.

9.Special automatic angle & edge trimming by the four edge folding system to ensure the quality of the finished product.

10.The hole machine adopts PLC control, featuring in simple operation. Errors are displayed directly on the touch screen,

which enables the operator easily solve the problem.

11. All main electronic components are use world famous brand. There is multi-language option in the computer,

so the operator can choose the language which they are familiar with. Automatic alarming for problem occuring.

E asy for operation and simple for maintenance.

Main technical specifications:

| Model | AHC-450A | AHC-540A |

| Paper size |

130*230mm(min) 480*830mm(Max) |

130*230mm(min) 570*830mm(max) |

| Paper weight | 100-200g/m2 | 100-200g/m2 |

| Cardboard thickness | 1-3mm | 1-3mm |

| Finished product size |

100*200mm(min) 450*800mm(max) |

200*200mm(min) 540*800mm(max) |

| Working speed | 25-30 sheet/min(max) | 25-30 sheet/min (max) |

| Motor power | 5KW | 5KW |

| Heating power | 6KW | 6KW |

| Dimensions | 7750*2320*1660(L*W*H) | 7750*2500*1660(L*W*H) |

| Weight | 3000Kg | 3300Kg |

We have other bigger sizes or special made models, welcome to contact us for more details!

All the machines will be well inspected and packed, then to load into the container, to guarantee you can get good condition machines.