- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

4500*1600*1380mm

-

Power (kW):

-

30.5kw

-

Weight (KG):

-

6500 kg

-

Weight:

-

6.5tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Diameter of roller:

-

125mm

-

Power of driving roller:

-

7.5KW*2

-

Power of pressurebar roller:

-

7.5KW*2

-

Diameter of driving roller:

-

125mm

-

Linear speed of host machine:

-

40-80m/min

-

Length of blade:

-

1500mm

-

Thickness of veneer peeler:

-

0.5-4mm

-

Diameter of peeler log:

-

32-400mm

-

Certification:

-

CE/SGS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

veneer peeling machine

-

Brand Name:

-

Sinoeuro

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

4500*1600*1380mm

-

Power (kW):

-

30.5kw

-

Weight (KG):

-

6500 kg

-

Weight:

-

6.5tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Diameter of roller:

-

125mm

-

Power of driving roller:

-

7.5KW*2

-

Power of pressurebar roller:

-

7.5KW*2

-

Diameter of driving roller:

-

125mm

-

Linear speed of host machine:

-

40-80m/min

-

Length of blade:

-

1500mm

-

Thickness of veneer peeler:

-

0.5-4mm

-

Diameter of peeler log:

-

32-400mm

-

Certification:

-

CE/SGS

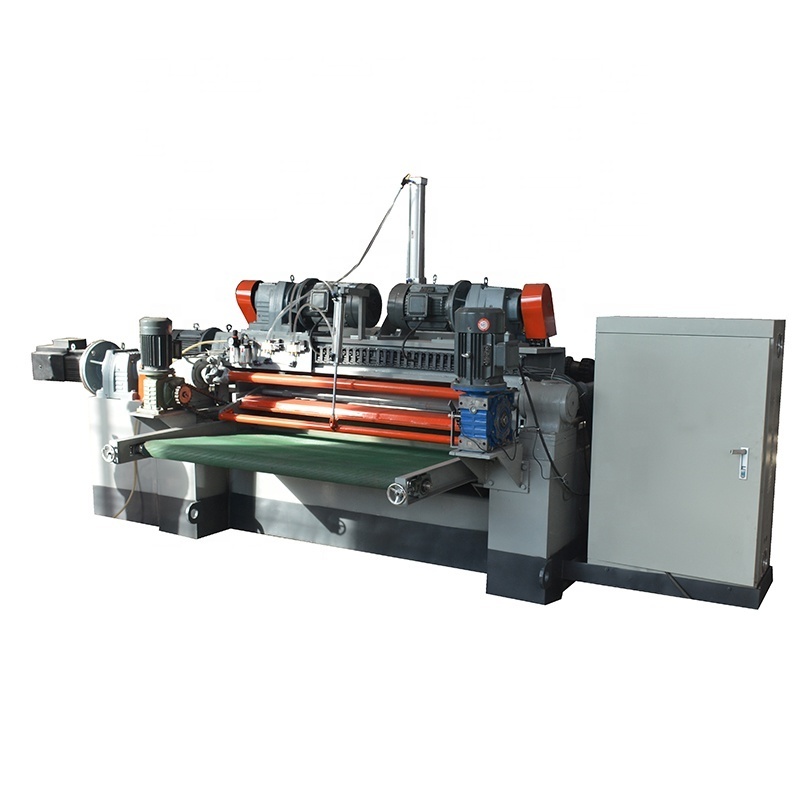

4FT Spindleless Core Veneer Peeling Machine

1. The feeding system adopts the screw and screw nuts. The screw nuts adopt the magnesium aluminum alloy, copper and other materials. So it is with long service life.

2. Automatic adjustment of cutting system, skin is much more uniform and smooth. Apply to woods with different diameters.

3. During the rotary cutting production, the machine can adjust the thickness of two kinds of veneer constantly and won't cause the crack of the veneers.

4. Block type screw and slider, high-precision and energy-saving.

5. The NC rotary and leather cutting are in one, so the machine is with high productivity and labor-saving.

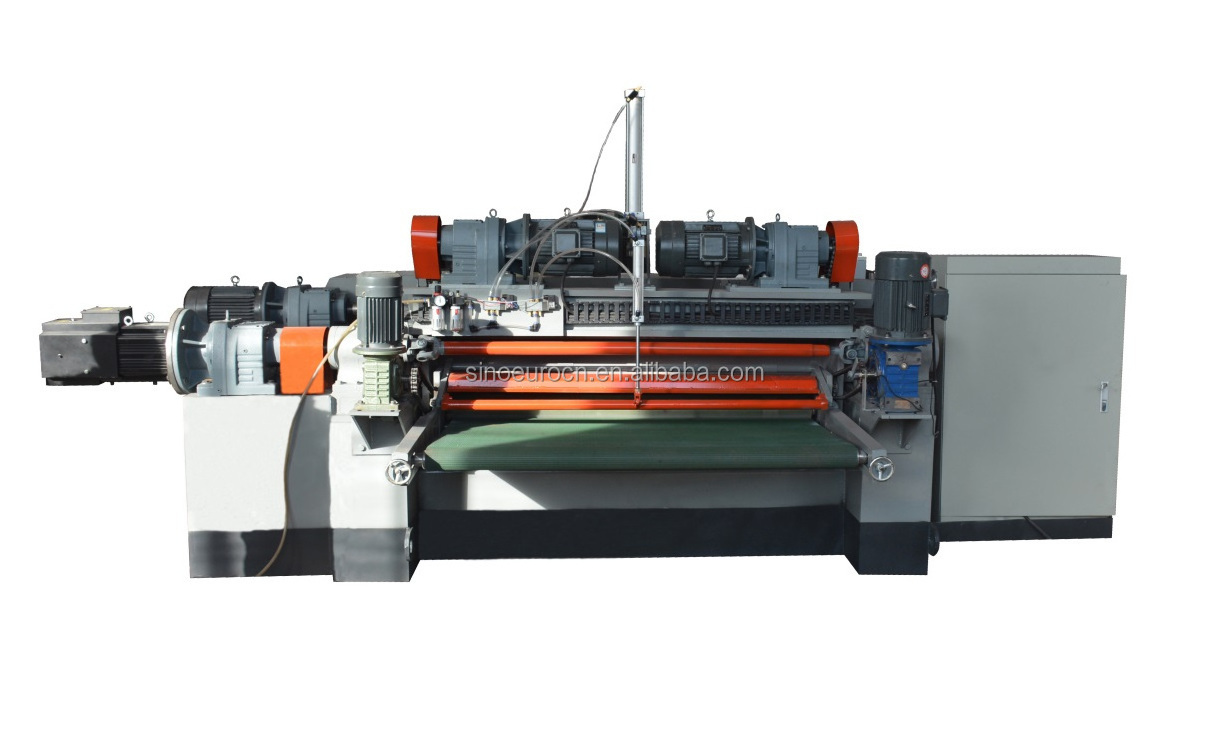

| Model |

48m/min normal type speed fix |

55m/min heavy duty speed fix | 40-80m/min heavy duty speed adjustable |

|

Picture |

|

|

|

| Peel length |

1300mm |

1300mm |

1300mm |

|

Opening |

500mm |

500mm |

500mm |

|

Remain logs diameter |

32mm |

24mm |

24mm |

|

Peel thickness |

1.0-2.8mm |

0.5-5.0mm |

0.5-5.0mm |

|

Cutting length |

660-1300mm |

500-2600mm |

500-2600mm |

|

Peel speed |

48m/min |

55m/min |

40-80m/min |

|

Single roller power |

7.5kw |

5.5kw × 2pcs |

7.5kw × 2pcs |

|

Double roller power |

7.5kw |

5.5kw × 2pcs |

7.5kw × 2pcs |

|

Feeding power |

5.5kw |

7.5kw( Servo motor ) |

7.5kw(Servo motor) |

|

Total power |

23.8kw |

33.2kw |

42.6kw |

| Roller diameter |

125mm |

125mm |

125mm |

|

Long-range control |

None |

Have |

Have |

|

Voltage |

380-515v |

380-515v |

380-515v |

|

Bottom structure |

160*65*3mm(Channel) |

8mm(Steel) |

8mm(Steel) |

|

Total weight |

4000kg |

6000kg |

6700kg |

|

Overall dimension |

4300*2500*1200mm |

4200*2500*1200mm |

4800*2500*1500mm |

| Machine bottom is made by steel instead of channel,more heavy and stable,after using 5 years will not become deformed | Servo Motor, More Precise | Hydraulic Blade Lifting, Easy to Change Knife |

| Our system have multilinggual translation,easy to opreate | Hardened Gear Reducer | We use famous brand for inveter,and the wire is stronger than others. |

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients’ special requirement, offering the reasonable plan and free design to help to select the equipment

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory

2) Oversea install and debug the equipment

3) Train the first-line operator

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging