The guarantee period of quality shall be 3 years counting from the date on which the commodity arrives at the port of destination.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.

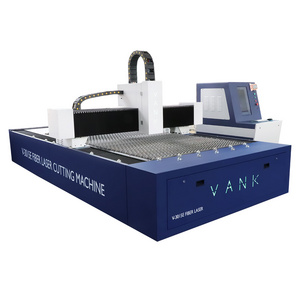

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

300*300mm

-

Cutting Thickness:

-

0-15mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Weight (KG):

-

500 KG

-

Product Name:

-

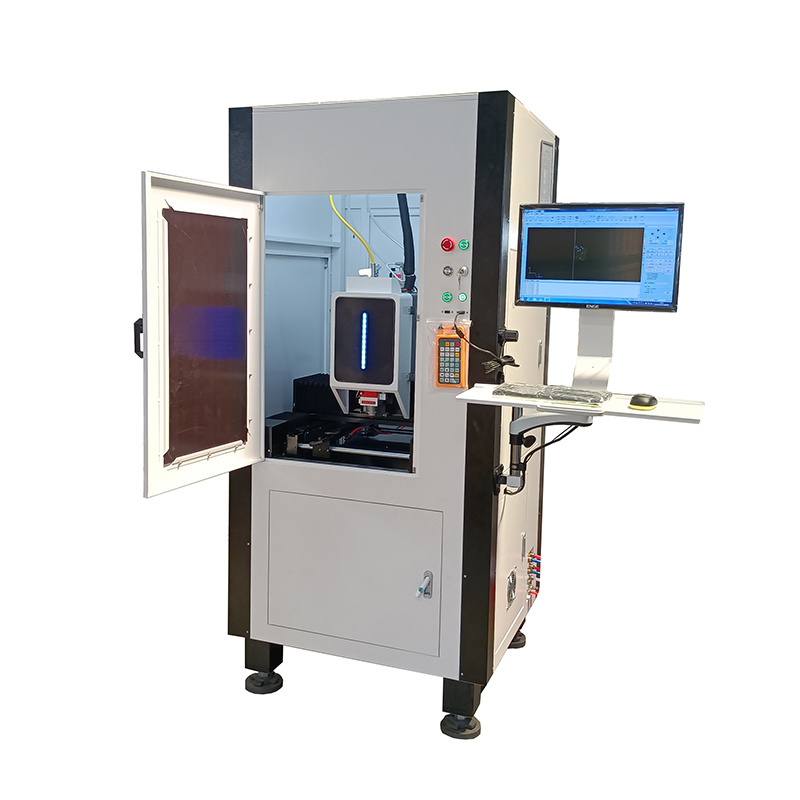

Mini fiber laser cutting machine

-

Laser Power:

-

1kw

-

Reducer:

-

French MOTOVARIO

-

Rack:

-

Taiwan YYC rack

-

Water chiller:

-

Hanli water chiller

-

Laser source:

-

JPT

-

working area:

-

300x300mm

-

Rail guide:

-

hiwin

-

laser head:

-

Raytools

-

Motor:

-

Japan imported

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

300*300mm

-

Cutting Thickness:

-

0-15mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Weight (KG):

-

500 KG

-

Product Name:

-

Mini fiber laser cutting machine

-

Laser Power:

-

1kw

-

Reducer:

-

French MOTOVARIO

-

Rack:

-

Taiwan YYC rack

-

Water chiller:

-

Hanli water chiller

-

Laser source:

-

JPT

-

working area:

-

300x300mm

-

Rail guide:

-

hiwin

-

laser head:

-

Raytools

-

Motor:

-

Japan imported

Product Description

The small high precision fiber laser cutting machine has advantages in metal cutting, mainly in the following aspects:

1. The small precision fiber laser cutting machine can guarantee the cutting process of small format, which is more suitable for some small pieces of metal materials, such as advertisements, kitchen utensils, etc. In comparison, the power is also lower than ordinary fiber laser cutting machines.

2. The cost of small precision fiber laser cutting machine is relatively low, which is very suitable for small enterprises or

enterprises with not much processing volume. The small precision fiber laser cutting machine has a relatively small footprint, so it is more convenient for placement and handling.

enterprises with not much processing volume. The small precision fiber laser cutting machine has a relatively small footprint, so it is more convenient for placement and handling.

3. The precision of the small precision fiber laser cutting machine is high, and the focused spot is relatively thin, the cutting surface is smooth. In addition, its cutting speed is also very fast.

|

Parameters of small high precision fiber laser cutting machine

|

|

|

|

Description

|

Parameter

|

|

|

Machine Model:

|

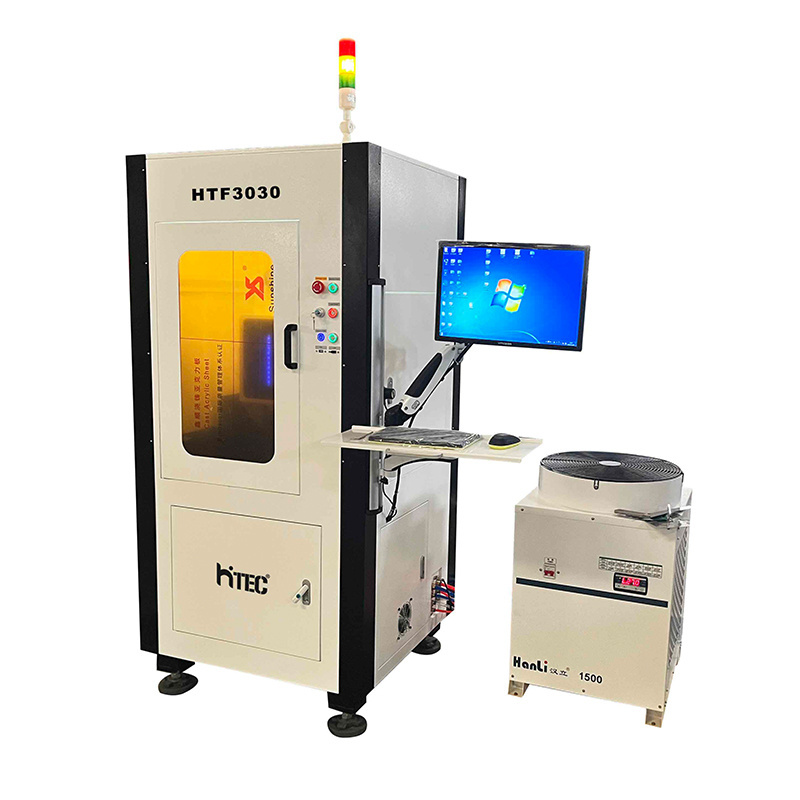

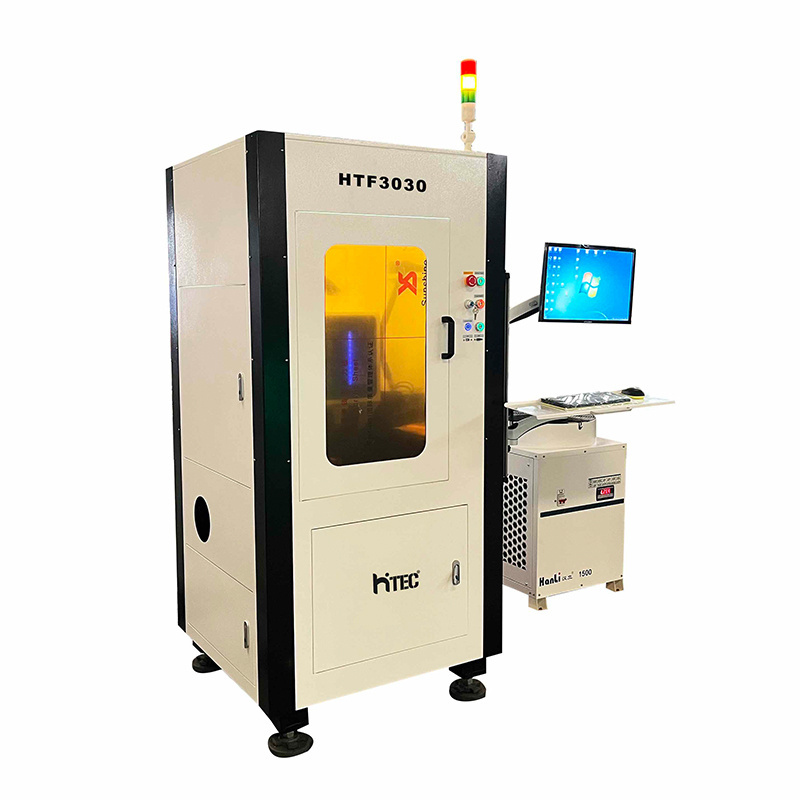

HTF-3030

|

|

|

Laser type :

|

JPT Fiber Laser Source

|

|

|

Laser power :

|

1000w/1500w/2000w

|

|

|

Weight:

|

500KG

|

|

|

Working area:

|

300x300mm

|

|

|

Repeated positioning accuracy :

|

±0.02mm

|

|

|

Max. Acceleration:

|

0.5G

|

|

|

Max.Running Speed:

|

40m/min

|

|

|

Transmission :

|

Double driver rack gear

|

|

|

Power consumption :

|

±0.015m

|

|

|

Machining accuracy:

|

220V/380V

|

|

Specification

Metal Sheet Fiber Laser Cutter Raytools laser head

Advantages:

--High Precision: without manual, zero fault.

--High Effectiveness: Without manual,Save time

--High Safety: Anti-collision design, height adjustment

--High sensitivity

Metal Sheet Fiber Laser Cutter JPT Laser generator

Long life time; More stable and cost-efficient;

Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

Japan Panasonic Servo motors and drivers on all axis

Taiwan TBI ball screw Transmission

Brand: Taiwan TBI Ball Screw

Details: High efficiency and high rigidity, long life, high-speed feed

Details: High efficiency and high rigidity, long life, high-speed feed

IPAD Designing Screen

Image display is more exquisite and delicate, the operation is smoother, The screen bracket can change the angle at will.

Shanghai Cypcut control system and software

Advanced technology, suitable for kinds of material cutting.

Water Cooling System

Brand: HanLi

Details: Dual cooling function, Hot water for laser Head and cool water for laser source to keep them around a certain temperature and guarantee their normally work.

Details: Dual cooling function, Hot water for laser Head and cool water for laser source to keep them around a certain temperature and guarantee their normally work.

Cypcut Remote control

HTF3030 is supplied with radio remote control for quick and easy positioning in X, Y and Z direction. The remote control also gives direct access to the functions: automatic focal length search, auxiliary gases purging, dry testing, contouring, pausing and stopping.

The remote control is magnetic and can be hung anywhere on the machine.

The remote control is magnetic and can be hung anywhere on the machine.

SMC electrical components

Samples

Cutting advantage of Metal Sheet Fiber Laser Cutter

1. High cutting precision: fiber laser cutting machine positioning accuracy 0.05mm, repeat positioning accuracy 0.03 mm. 2. fiber laser cutting machine slit narrow: the laser beam is focused into a small spot, so that the focus reaches a very high power density, the material is quickly heated to the degree of gasification, evaporation to form holes. As the beam moves relatively linearly with the material, the holes are continuously formed into slits having a narrow width, and the slit width is generally 0.10-0.20 mm.

3. The cutting surface of the fiber laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the cutting surface is generally controlled within Ra6.5.

4, fiber laser cutting machine speed: cutting speed up to 10m / min maximum positioning speed up to 30m / min faster than wire cutting speed.

5. fiber laser cutting machine cutting quality is good: no contact cutting, cutting edge is affected by heat, there is basically no thermal deformation of the workpiece, completely avoiding the collapse formed when the material is punched and sheared, the slit generally does not require secondary processing.

6, no damage to the workpiece: the fiber laser cutting head will not contact the surface of the material to ensure that the workpiece is not scratched.

7, not affected by the shape of the workpiece: laser processing is flexible, can process any graphics, can cut pipes and other profiles.

8. fiber laser cutting machine can cut a variety of materials: such as plastic, wood, PVC leather, textiles, plexiglass and so on.

9. Saving mold investment: laser processing does not require molds, no mold consumption, no need to repair molds, saving mold time, thus saving processing costs and reducing production costs, especially suitable for processing large products.

10. Material saving: computer programming can be used to cut products of different shapes to maximize the utilization of materials.

11. Improve the speed of sample delivery: After the product drawings are formed, laser processing can be performed immediately, and the new product can be obtained in the shortest time.

12, safety and environmental protection: laser processing waste, low noise, clean, safe, non-polluting, greatly improving the working environment.

Customer feedback

QC And Service

QC

5 face cnc milling machine which process accurancy can be 0.001mm,to improve all the machine hardware precision,from machine bed,gantry parts to tapping.

All the machine parts Assembe by our machine milling and lathe machine,can be guarantee the machine precision and fast delivery time

Certification

CE certification

Service

Technology support

We welcome all our buyers come to visit our factory for directly free training, our professional engineer will support you to study the machine operation.

We will supply machine operation manual, training videos and machine parameters, our engineer will supply online machine installation and training.

The customers’ technicians can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems as soon as possible.

If customer need, we will send our engineer to the customers’ place to provide install and train the customer to use the

machine,our engineer will stay at customers’ place for 5-7days,customers should pay the round-trip airkets/hotels/food for our engineer.

The main purpose of pre-sales service is to assist customers to do engineering planning and system requirements analysis, so that

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

1. Strengthen user communication and exchange on project progress at any time; 2. As far as possible to meet the changes of the

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Guarantee Policy

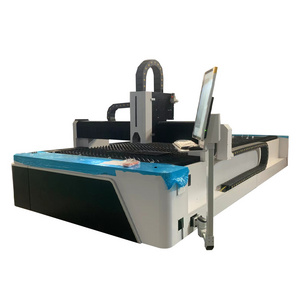

Related product

Company Profie

Established in the year 2002,An ISO 9001 Firm.We are manufacturer and develop of the high technology machines.Hitec products are used in a wide variety of industries,markets and applications thoughout all over the world.

Hitec is highly committed to offering the most advanced,capable and efficient manufacturing technology backed by unsurpassed service and support. We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

FAQ

Q1: I need a fiber laser cutting machine, can you give me some suggestions?

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

It can process most of metal

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this Professional manufacturer for fiber laser cutting machine?

For standard machines, it would be 30 days; For non-standard machines and customized machines according to client s specific requirements, it would be 30 to 35 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

It can process most of metal

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this Professional manufacturer for fiber laser cutting machine?

For standard machines, it would be 30 days; For non-standard machines and customized machines according to client s specific requirements, it would be 30 to 35 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.

Hot Searches