- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Drilling Tricone Bit Breaker Used For Tricone Roller Cone Bit

-

Application:

-

Oil Field ,water well and geothermal drilling

-

model:

-

6"~26"

-

packaging:

-

wooden case

-

color:

-

as your demand

-

material:

-

carbon steel

-

Certification:

-

API

-

MOQ:

-

1pc

-

Usage:

-

for tricone bit and PDC bit

-

Advantage:

-

convenient

Quick Details

-

Weight (KG):

-

70

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

crossing

-

Product name:

-

Drilling Tricone Bit Breaker Used For Tricone Roller Cone Bit

-

Application:

-

Oil Field ,water well and geothermal drilling

-

model:

-

6"~26"

-

packaging:

-

wooden case

-

color:

-

as your demand

-

material:

-

carbon steel

-

Certification:

-

API

-

MOQ:

-

1pc

-

Usage:

-

for tricone bit and PDC bit

-

Advantage:

-

convenient

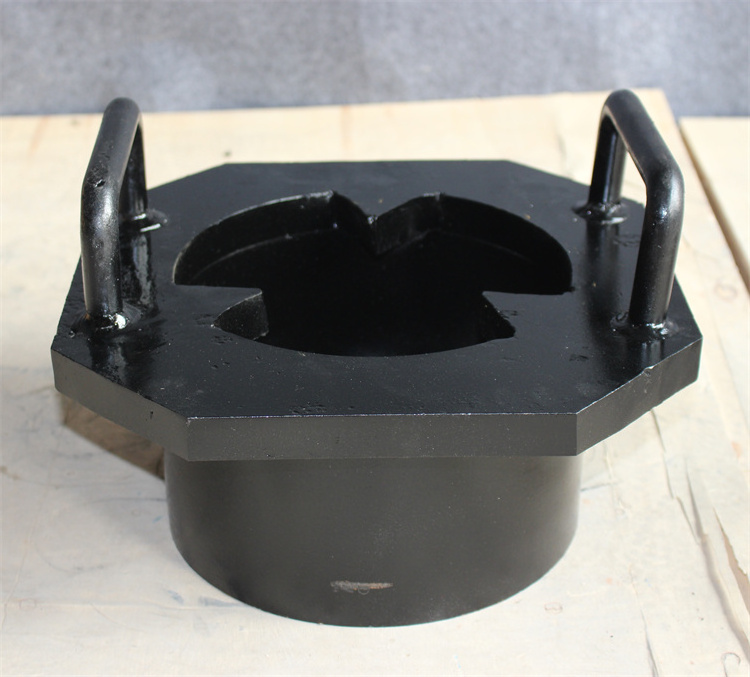

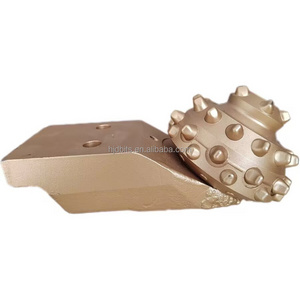

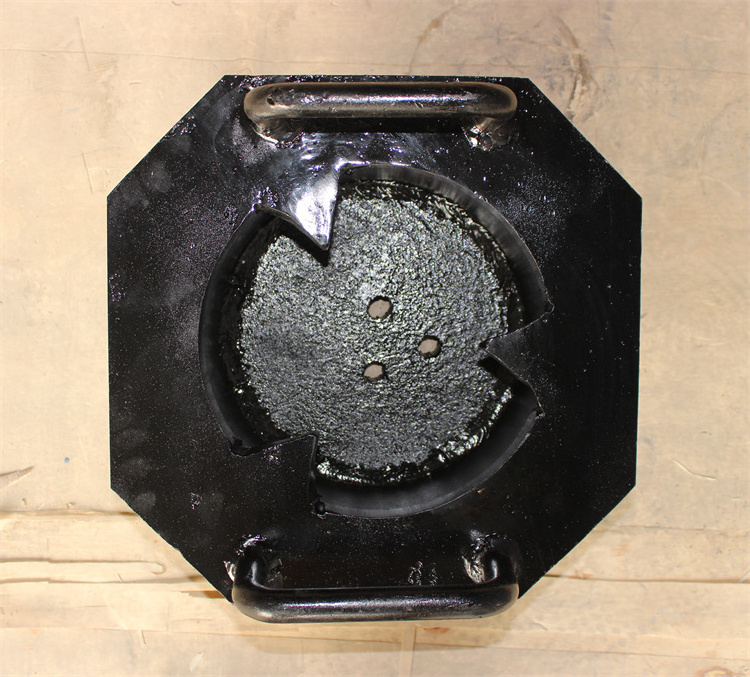

Drilling Tricone Bit Breaker Used For Tricone Roller Cone Bit

|

Formation |

||

|

The tricone Bit Breakers are suitable to make up or break out the drilling bit during the oil well drilling and repairing operations. The Users should be chosen the bit breaker according to the size and model of the drilling bit. Feature: Improve support and retention Advantage: Manage the magnitude cutter loading and bit torque Benefit: Improved bit durability and directional responsiveness Advantage: Higher nozzle counts and/or fixed ports to best serve cleaning, cooling and cuttings evacuation requirements with available hydraulic flows. Allow for higher flow rates with minimal |

||

|

Advantages |

||

|

1. Bit breaker is mainly used to screw on or off a rock bit to the bottom of drill string. 2. It can also prevent the rock bit from dropping into well hole. 3 . The price of it is cheap and the use of it is safety and reliable. 4 . It is easy to operate. First, the bit breaker is placed on well hole and then put the rock bit onto it. |

||

|

Parameters |

||

|

Serial No. |

Bit Size |

Bit Model |

|

1 |

4 1/8" - 4 3/4" |

Tricone Bits |

|

2 |

5 5/8" - 5 7/8 " |

Tricone Bits |

|

3 |

6" - 6 1/4 " |

Tricone Bits |

|

4 |

6 1/2 - 6 3/4 " |

Tricone Bits |

|

5 |

7 3/8" - 7 1/2 " |

Tricone Bits |

|

6 |

8 3/8" - 8 5/8" |

Tricone Bits |

|

7 |

8 3/4" - 9" |

Tricone Bits |

|

8 |

9 1/2" |

Tricone Bits |

|

9 |

9 5/8" - 9 7/8" |

Tricone Bits |

|

10 |

10 5/8" - 11" |

Tricone Bits |

|

11 |

11 3/4" - 12 1/4" |

Tricone Bits |

|

12 |

13 3/4" |

Tricone Bits |

|

13 |

14 3/4"- 15" |

Tricone Bits |

|

14 |

16" |

Tricone Bits |

|

15 |

17 1/2" |

Tricone Bits |

|

16 |

18 1/2" |

Tricone Bits |

|

17 |

20" |

Tricone Bits |

|

18 |

22" |

Tricone Bits |

|

19 |

23" |

Tricone Bits |

|

20 |

24" |

Tricone Bits |

|

21 |

26" |

Tricone Bits |

|

22 |

28" |

Tricone Bits |

- Please select the applicable formation and parameters according to the instructions.

- Carefully check the bits appearance and to check the bits threaded end face,whether the serial number on the box and certificate.

- Selection of WOB and RPM should be within the limits of the recommended parameters, higher WOB and RPM cannot be used simultaneously.

- Bottom hole must be clean and bit must not be used for long section reaming.

- Drilling process must operate smoothly, find that there is Bie jump on abnormal phenomenon, should be timely analysis and take effective measures

- The bit should be kept indoor with dry and well ventilated conditions at 10-33℃ and kept from sunshine and rain. Stored under such conditions, quality of bit is guaranteed for 4 years.