- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

aluminum ball 6mm

-

Product:

-

1mm aluminum sphere

-

Experience:

-

Professional Steel Ball Manufacturing Since 1988

-

Special Types:

-

Solid / Hollow Alumium Ball

-

Surface:

-

Polished Finish

-

Grade:

-

G500

-

Tolerance:

-

±0.01mm ~0.05mm

-

Hardness:

-

Unhardened

-

Size Ranges:

-

OD 0.5mm to OD 75mm

-

Product Shape:

-

Spherical

-

Material Standard:

-

GB AISI ASTM JIS DIN BS UNI SIS NF CSN

Quick Details

-

Material:

-

alumium steel

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Decok Steel Ball Metal Spheres

-

Model Number:

-

aluminum ball 6mm

-

Product:

-

1mm aluminum sphere

-

Experience:

-

Professional Steel Ball Manufacturing Since 1988

-

Special Types:

-

Solid / Hollow Alumium Ball

-

Surface:

-

Polished Finish

-

Grade:

-

G500

-

Tolerance:

-

±0.01mm ~0.05mm

-

Hardness:

-

Unhardened

-

Size Ranges:

-

OD 0.5mm to OD 75mm

-

Product Shape:

-

Spherical

-

Material Standard:

-

GB AISI ASTM JIS DIN BS UNI SIS NF CSN

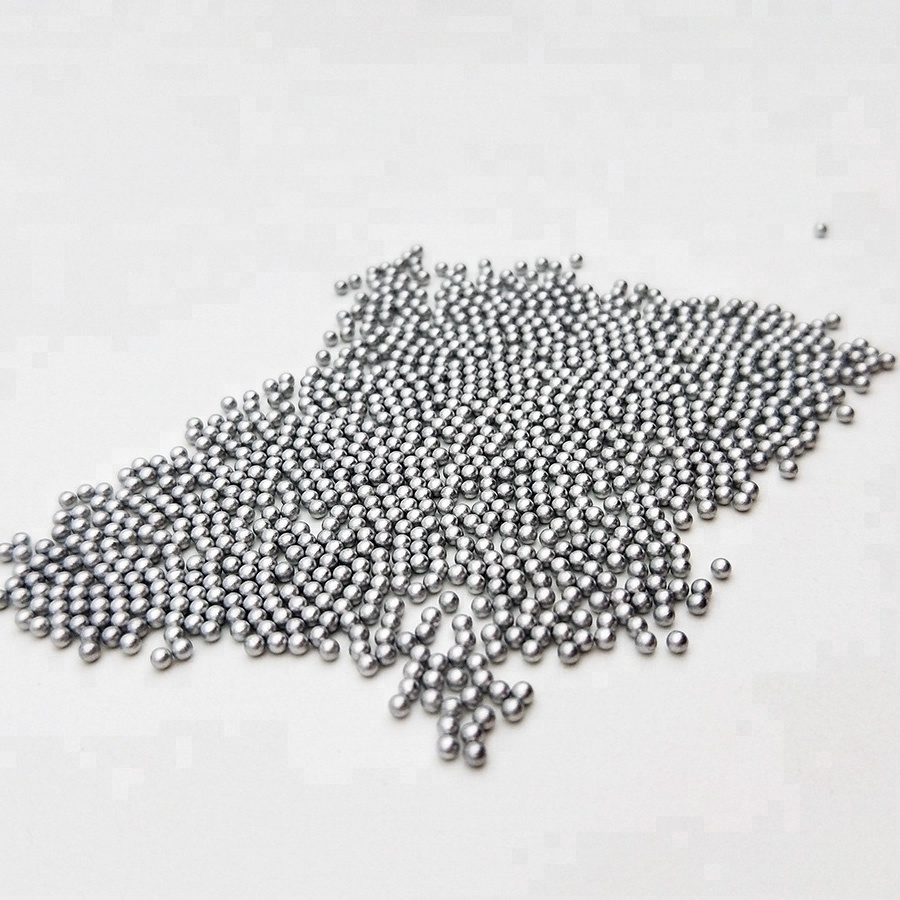

solid metal ball good quality 1mm aluminum sphere

1-MingLiang Shine Steel Ball Factory Produces Alumium Ball I ncluding:

Material:

Pure alumium ball

Type:

Solid alumium ball

Hollow alumium ball

Solid alumium ball with drilling hole

Hollow alumium ball with drilling hole

Hardness:

Unhardened alumium ball

Surface treatment:

Polished alumium ball

2-Basic informations of Shine alumium ball

|

Diameter |

0.5-75 mm |

|

Precision Grade |

G500 (ISO3290) |

|

Hardness |

Soft - unhardened |

|

Surface |

polish finish |

|

Special Types |

solid alumium ball ( with drilling hole ) Hollow alumium ball ( with drilling hole ) |

3-Features of alumium ball

Commercially pure aluminum balls,light balls in silvery white color featured by good corrosion and wear resistance, very good surface finishing. Balls are not heat treated. Balls can be provided in the passivated conditions.

4-Applications of alumium ball

Special bearings and valves, sealing elements (crushed balls), they are used in automotive industry (safety devices), aviation and aerospace industry, electronic industry, welding processes and often used as closures.

5-Chemical Analysis

|

Pure Alumium Ball

Al 99.7max % Si 0.2 max % Fe 0.25 max %

Cu 0.03 max %

|

6- MingLiang Shine Steel Ball Package Options

Package is as flexiable as customized accepted.

Package 1: PP bag+carton.

P ackage 2: PP bag+carton+wooden case+pallet.

Package 3: PP bag+bubble bag+inner box+carton.

No comfirmed carton dimension due to ball sizes differences.

MingLiang Steel Ball Factory was founded in 2000 and is well known professional precision manufacturing in the production of steel ballls in China.

The specific power of SHINE is the wide range of sizes,metal materials and grades completely available in one source of supply.

The Factory is employing 88 people and covers 6,000 square meters including headquarters, workshop,warehouse,quality control department.

The QC Dept is equipped with high tech control machines testing all technical features of each batch products.

Our warehouse is constantly filled with more than 3000 TONS of finished goods in order to satisfy in the shortest terms the requirements of our customers.

Welcome to visit Shine at your proper time.

9-Advantages of MingLiang Steel Balls

26 years experiences of professional precision manufacturing of steel balls

Products were RoHs certified by SGS

Small MOQ

Fast delivery based on quality guaranteed

None-standard sizes of steel balls supplied

Special types ( drilled, threaded,hollow,plating finish,satin finish,matt finish ) supplied

10-How A Steel Ball Is Made

1) Wire coil: Steel wire of specific material and size were inspected for correctness.

2) Cutting: The wire is cut into required length.

3) Forging/heading: Spherical shapes between dies are formed.

4) Deflashing: The flash line along the circumference is removed.

5) Heat treatment: Carbon steel and chrome steel balls are through hardened.

6) Cleaning/descaling: Basic surface cleaning is done.

7) Hard grinding / filing: An exacting process to achieve required sphericity and size of the steel ball.

8) Lapping: The final surface finish is acquired through this process.

9) Polishing / bunishing: Surface luster, working hardening, higher product life is achieved.

10) Passivation: Carryover iron and other contaminants are removed and a surface film prevents atmospheric and water corrosion on stainless steel balls.

11) Inspection: For surface finish,size and tolerance.

12) Rust preventive oil: Applied on carbon and chrome steel balls to save from rusting and corrosion.