- Product Details

- {{item.text}}

Quick Details

-

Hydraulic system pressure:

-

15MPa

-

Oil tank capacity:

-

60L

-

Corner assemble:

-

0-50mm

-

Max. dimension of window:

-

1800*3000mm

-

Min. dimension of window:

-

510*510mm

Quick Details

-

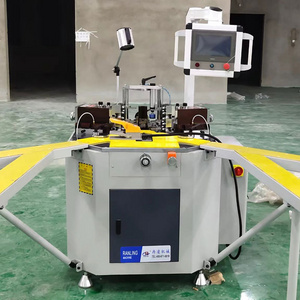

Product name:

-

Aluminum Window Corner Crimping Machine

-

Air pressure:

-

0.5-0.8MPa

-

Air consumption:

-

0.45L/time

-

Hydraulic system pressure:

-

15MPa

-

Oil tank capacity:

-

60L

-

Corner assemble:

-

0-50mm

-

Max. dimension of window:

-

1800*3000mm

-

Min. dimension of window:

-

510*510mm

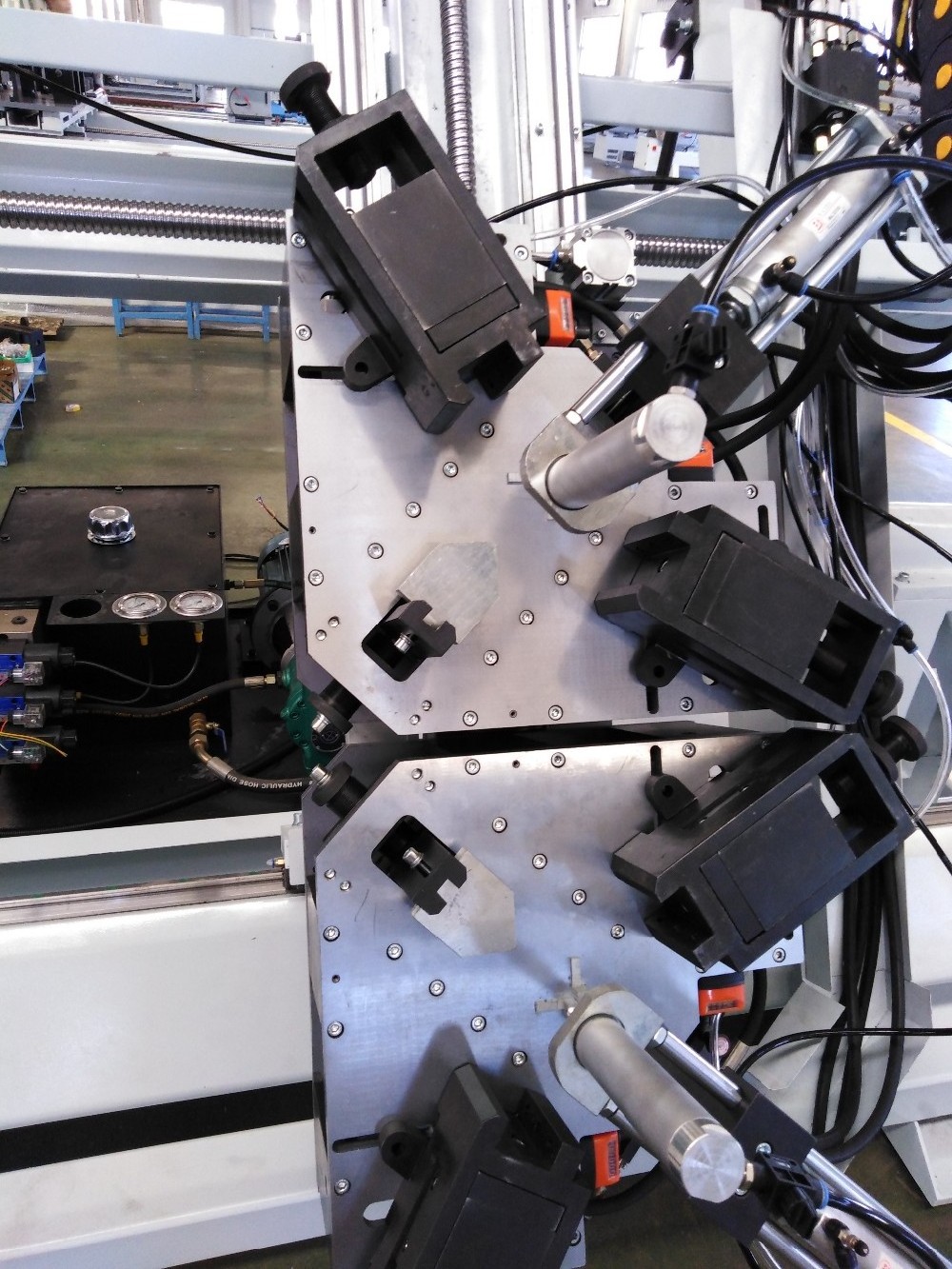

1. Fuselage of entire machine design scientific, reasonable and steadily. And it welds with square steel pipe with the thickness of 10mm and make products steady when combining the corner.

2. Adopt the plunger type large-scale hydraulic pressure station, the pressure stable, offered the pressure well and the noise is low.

3. The electrically controlled box independent laying independently. It is convenient, even more is advantageous for the crimping angle quality real-time monitoring. The transmission connection uses the aerospace special-purpose receptacle, safe and stable.

4. Adopt original installation import flat square guide rail, which can guarantee the precision of the heads when moves horizontally. Transmission adopts the original imported installation ball bearing master screw.

5. The precision is extremely high so it can guarantee group angle quality.

6. The servo controlling machines, servo motor, person-machine touching the contact surface are adopt the original imported installation of Japanese Mitsubishi system, and the increase assistance brake system. It is stable and efficiency.

7. The processing smallest scope is may reach 510x510mm, the manual mediation can realized to 500x500mm, it can suitable for all kinds of windows and doors that enterprise's processing to need.

8. Used for corner punching and riveting combination of aluminum window and door four corner connecting at one time is available which greatly increased the production efficiency.

9. Clamping device can adjust forward and back, it is easy to operate.

10. Adopt CNC system can realize automatic and accurate locating thus can produce high accuracy windows.

11.Wide profile processing range due to convenient corner combining cylinder detting.

12.Suitable for various kinds high quality and high volume windows production.

Packing Details : Wood packing

Delivery Details : 10-60 days (It depends on whether it's customized or not)

Founded in 2003, Parker Machinery Co., Ltd has developed an assembly line for door, window, curtain wall and insulating glass equipment. With over ten years' production experience, Parker has become a leading manufacturer of window door machinery in China. The operation of high precision, advancement and specialty ensure that we are able to supply high-quality window and door equipment for customers.

During the past few years, Parker has made great progress and has become well known and outstanding in domestic fairs for window door machinery. With advanced technological equipment, tremendous technical strength and reliable product quality, our window and door equipment has been well received by customers from Russian, Kazakhstan, Vietnam, Iran, etc. We have a perfect sales network and complete service system in China. We are also taking a leading role in setting branch companies abroad.

Parker Company Video link:

https://www.youtube.com/watch?v=hYwmgxfRge4

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Ten to sixty days(It depends on whether it's customized or not)

Q: What is your terms of payment ?

A: T/T L/C

If you have another question, pls feel free to contact us as below: