- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

102*48*98cm

-

Power (kW):

-

11kw

-

Weight (KG):

-

360 KG

-

Marketing Type:

-

Hot Product 2024

-

Die Diameter:

-

229mm

-

Die Hole Specification:

-

2.5-10mm

-

Color:

-

As request

-

Certification:

-

CE

Quick Details

-

Pellet Diameter (mm):

-

2 - 10

-

Output (kg/h):

-

180 - 250 kg/h

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

102*48*98cm

-

Power (kW):

-

11kw

-

Weight (KG):

-

360 KG

-

Marketing Type:

-

Hot Product 2024

-

Die Diameter:

-

229mm

-

Die Hole Specification:

-

2.5-10mm

-

Color:

-

As request

-

Certification:

-

CE

Home use mini wood pellet press mill price

| Poultry Feed Pellet Machine | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Model: MKL225, MKL229, MKL295 Remarks: 1) the Model number means the diameter of the flat die of the feed pellet machine 2) the diameter of the final product pellet is Φ2.5-10 mm . |

||||||||||||||||||||||||||||||||||||

|

Model: MKL225 Capacity : 120-200kg/h Power : 7.5Kw Weight : 260kg Dimension : 100*45*98cm |

|||||||||||||||||||||||||||||||||||||

|

Model: MKL229 Capacity :180-250kg/h Power : 11Kw Weight : 360g Dimension : 102*48*98cm |

|||||||||||||||||||||||||||||||||||||

|

Specifications |

|||||||||||||||||||||||||||||||||||||

|

♦This series machine can be powered by diesel engine and electric engine. We adopt the new design of direct connection of motor shaft and he main shaft that overcome the loose defect of belt connecting as long time using. High accuracy gearbox and high output. ♦It is widely used in large,middle, small scale aquatic. food and feed processing factory, livestock farm, poultry farm, individual raisers, middle and small farm. ♦International advance steam fittings and imported pressure reduction valve. ♦Flat die is made with international advanced equipment for long lifespan. ♦Drive with heavy duty gearbox, which can produce continuously in most adverse condition.

|

|||||||||||||||||||||||||||||||||||||

|

All KL Series Feed Pellet Machines |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

The advantage of our roller and die |

|---|

|

Robust construction Non-corrosive Excellent design High compressive strength The diameter of die holes rang from 2.5-10 mm and we can also supply different dies molds according to your needs. This household pellet mill has a rotating roller and a stationary die design. Once the powder drops into the mill, the rollers will spin with the diesel engine to force the powder through the holes of dies. In this way different size pellets will be made. |

|

|

|

Guarantee of Our Feed Pellet Machines |

|

Our pellet mills are guaranteed with 1 year quality assurance from the date of goods shipment. What is the terms of warranty and spare parts? When we are talking about spare parts for a pellet mill, by and large, we are talking about die, roller and bearing. Practically, that how often you will need to renew spare parts is depending on what raw material you are making pellets from. Apparently, compared with making straw pellets, pellet mill that are making wood pellets requires a higher frequency for changing spare parts. We supply clients with high quality pellet mill dies, rollers, bearings and other parts. Clients are available to order at anytime. If you need spare parts, please contact me or test message. |

|

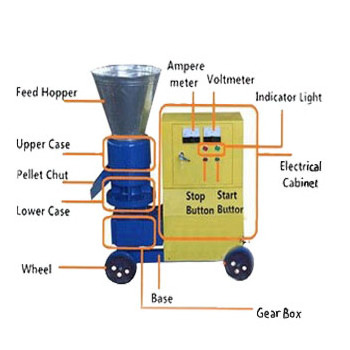

Knowing About Your Machine |

|

|

| Making Your Own Pellets as Stove Fuel |

|---|

|

Advantages of Making Your Own Wood Pellets as Stove Fuel 1. You can determine what to feed your animals and in what ratio. 2. Pelletized feed can be stored for a long time with less wastage and they save storage space. 3. Pelletized feed can be transported more easily. 4. Feed pellets can prevent animals from selective feeding habit and they have a 145% higher conversion ratio. 5. Due to dust inhalation, feed pellets can reduce the respiratory disease in animals especially in horses. 6. Feed pellets benefit the good performance of animals.

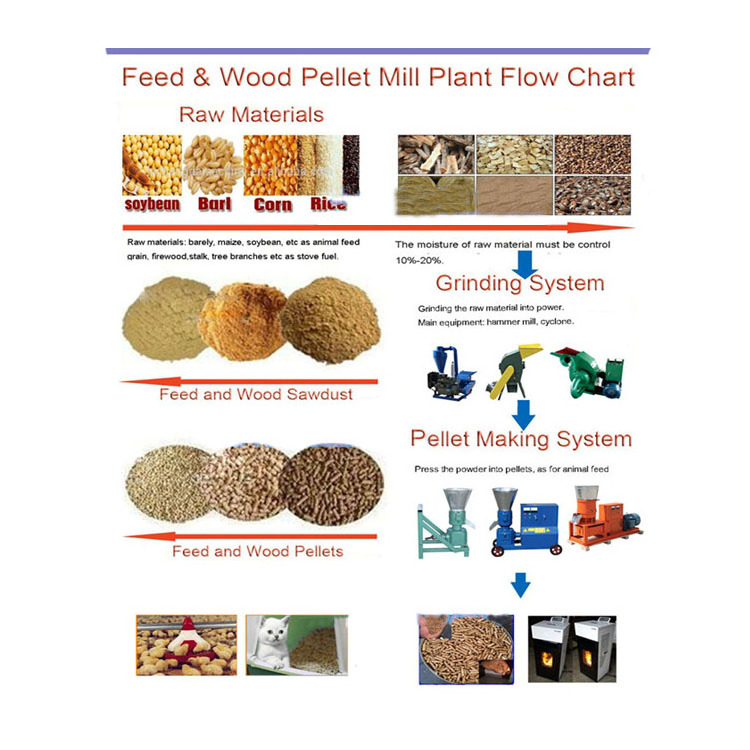

Raw materials for biomass pellets mainly contain: wood shavings, tree branches and other parings from furniture manufacturers or wood working factory; <img wood wastes including pine tree waste, spruce tree waste and other sawdust wastes. In the process of making wood pellets, the lignin and resin of woods can serves as binder for pellet pelletizing. So there is no need to add any additives. If you produce pellets at home, the biofuel pellets produced by portable pellet mills can bring you a warm winner for fireplace or supply as fuel for cooking.

|

| CE Certification of Wood Pellet Mills | |

|---|---|

|

|

|

|

Packing & Delivery |

|---|

|

To make sure the machine delivery to you at the best condition, we adopt the considerate way to protect the equipment very well. We consider our products just as our children.

|