- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HJ

-

Year:

-

2023

-

Voltage:

-

220

-

Weight (T):

-

0.6 T

-

Motor Power (kw):

-

4.5 kw

-

Product name:

-

Servo electronic press

-

Key words:

-

Servo electronic press

-

Material:

-

Steel Material

-

Display:

-

Touch Screen

-

Usage:

-

Universal Testing Equipment

-

Power supply:

-

AC220V,50Hz

-

Weight:

-

150Kg

-

Color:

-

Customer Required

-

Size:

-

Custom Size

-

MOQ:

-

1 Pcs

Quick Details

-

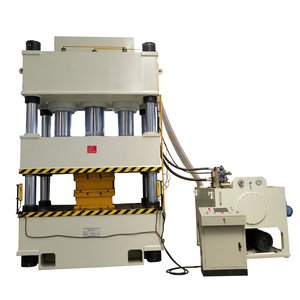

Machine Type:

-

Four-column Four-beam Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Return Force (kN):

-

40 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HJ

-

Year:

-

2023

-

Voltage:

-

220

-

Weight (T):

-

0.6 T

-

Motor Power (kw):

-

4.5 kw

-

Product name:

-

Servo electronic press

-

Key words:

-

Servo electronic press

-

Material:

-

Steel Material

-

Display:

-

Touch Screen

-

Usage:

-

Universal Testing Equipment

-

Power supply:

-

AC220V,50Hz

-

Weight:

-

150Kg

-

Color:

-

Customer Required

-

Size:

-

Custom Size

-

MOQ:

-

1 Pcs

Product Paramenters

introduce

Servo electronic press

The CNC servo electronic press is referred to as the electronic press, and its working principle is that the servo motor drives the ball screw to carry out the pressure assembly operation. It can realize the whole-process closed-loop control of the press-fitting force in the press-fitting operation.

Refractory industry: forming of refractory bricks, special-shaped refractory bricks and refractory balls.

Automobile industry: press-fit engine components (cylinder head, cylinder liner, oil seal, etc.), press-fit steering gear components (gears, pin shafts, etc.), press-fit drive shaft components, press-fit gearbox components, brake disc components, etc.

Motor industry: Press-fit micro-motor components (spindle, housing, etc.) to motor components (bearings, spindles, etc.). Electronics industry: press-fit circuit board components (plug-ins, etc.), electronic components.

Home appliance industry: home appliance accessories, riveting of home appliance accessories, etc.

Machinery industry: mechanical parts, automatic assembly line, life test of wearing parts, etc.

Product features

Press-fitting with five stroke speeds;

On-line pressing quality judgment;

Press-fit curve display;

Seven pressing modes are available for selection;

100 sets of pressing procedures can be set;

Pressing data transmission and storage.

Features

Provide 30-100KN settable pressing force (set directly on the touch screen)

The upper and lower limits of the

interference force alarm, and five points are taken for comparison during the press-in process; Interference data storage

interference force alarm, and five points are taken for comparison during the press-in process; Interference data storage

function, and can be exported to a personal computer, and opened in EXCEL form for easy query;

The modification and call of parameters can only be operated through the password input mode. There are 9999999 sets of press-fit parameters that can be stored. The administrator has the right to modify and save the parameters, and the operator only has the right to call in the selection drawing number;

It has a peak value alarm function, that is, it can capture the pressure of the force sensor for each pressing of the device, and then perform an upper and lower limit alarm to prompt whether the set pressure and the actual pressure are within the difference range;

It can make corresponding text prompts for the alarms sent by the equipment; 7. Real-time display of press-fit curves of force and displacement pressure; 8. Realize the current pressing position with the accuracy of ±0.01MM;

It can compare the upper and lower limits of the final press-fitting position, and can detect missing or mis-installed

spare parts and other reasons that are not assembled in place;

spare parts and other reasons that are not assembled in place;

The lifting stop position, deceleration position and descending safety position can be set on the touch screen. compress time;

With manual/automatic function: when the manual function is in the mold, press the corresponding button to get the corresponding action, and the hand will stop immediately. Automatic function Press the corresponding button, the pressure head goes down quickly → down slowly → pressurize → maintain pressure → the pressure head returns automatically.

It is equipped with two-hand button start (the two buttons are pressed at the same time within 0.5 seconds to be effective), and there is an emergency recovery button. 13. It has two-color warning lights and a buzzer, and it will alarm with sound and light in case of failure.

With infrared safety grating protection. When the oil cylinder is pressed down, if an object with a diameter of 25mm penetrates into the machine, the oil cylinder will rise immediately and give an audible andvisual alarm

Products Description

Hot Searches