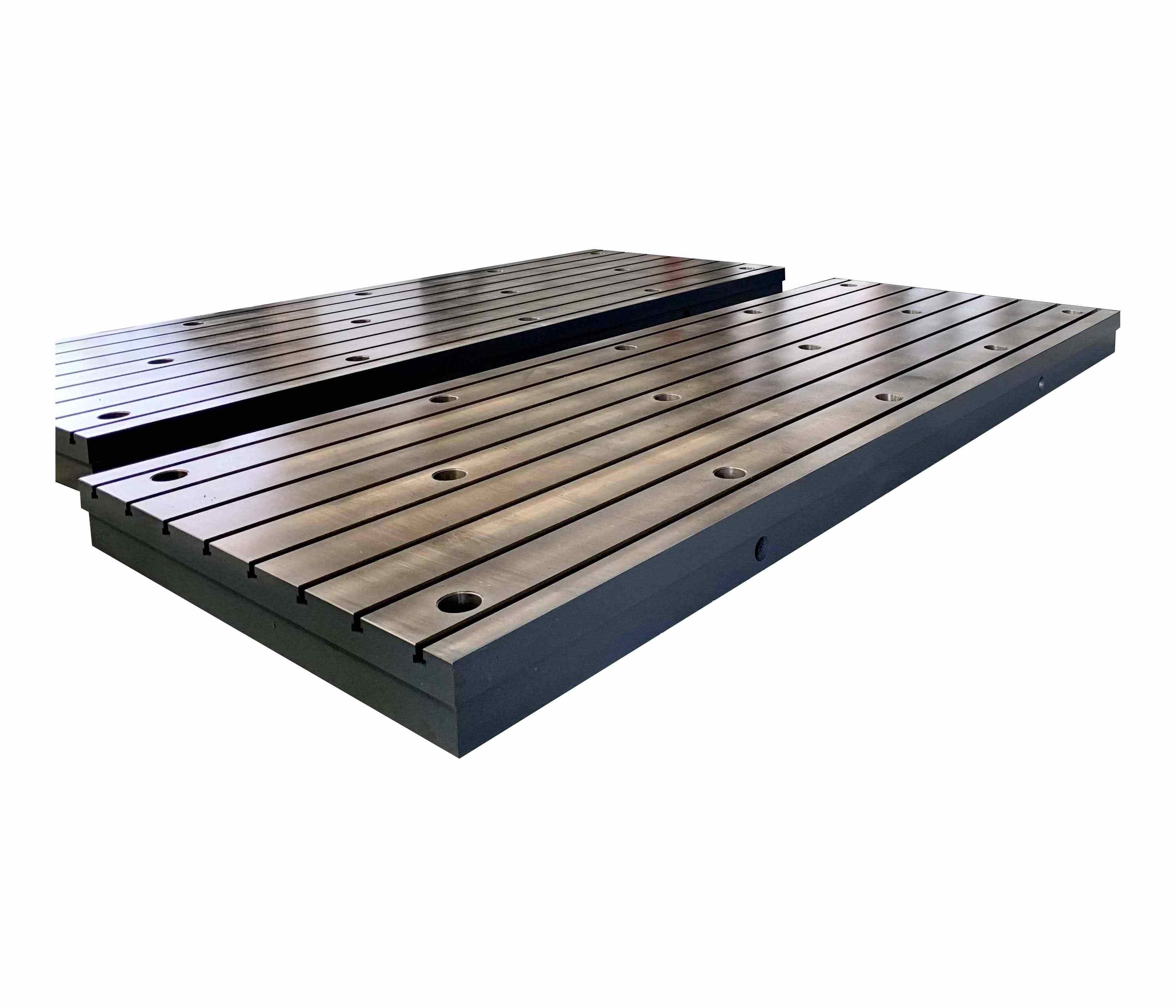

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

steel

-

Process:

-

casing&machining

-

Type:

-

OEM Casting Parts

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Usage:

-

Industrial

-

Certification:

-

ISO9001/ISO14001

-

Design Process:

-

MAGMA simulation software

-

Size:

-

Customer's 3D Drawing(oversized)

-

Quality Control:

-

100%

-

Molding pattern:

-

Wood pattern,lost foam pattern

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

OEM/ODM

-

Material:

-

steel

-

Process:

-

casing&machining

-

Type:

-

OEM Casting Parts

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Usage:

-

Industrial

-

Certification:

-

ISO9001/ISO14001

-

Design Process:

-

MAGMA simulation software

-

Size:

-

Customer's 3D Drawing(oversized)

-

Quality Control:

-

100%

-

Molding pattern:

-

Wood pattern,lost foam pattern

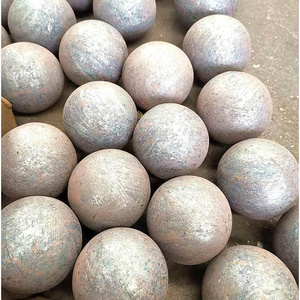

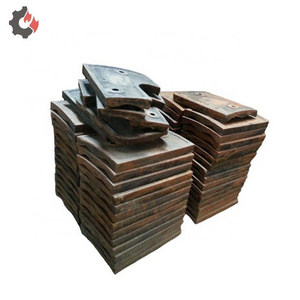

Main Cast Iron Material

Main Cast Steel Material

Carbon Steel -

(WCB,WCC,LCC,etc)

Martensitic Stainless Steel -(CA15,CA6NM,etc.)

Austenitic Stainless Steel -(CF8,CF3,CF8M,CF3M,etc.)

Duplex Steel&Super Duplex Steel -(1A, 1B, 1C, 2A,3A,4A,5A,6A,etc.)

High Temperature alloy Steel -(904,904L,20#,etc.)

Hastelloy -(B,C)

【Pouring Efficiency】

- Electric Furnace, Capacity: 15ton--2 sets & Capacity: 25ton--2 sets.

【MAGMA】

- The most advanced simulation assisting process design software.

【Casting process】

- Wooden pattern - lost foam pattern - aluminium pattern

【Machining process 】

- High quality CNC machining

【Quality Assurance 】

- Full set of testing equipment.

【Price Advantage】

- Offering the best casting services at the most competitive prices our priority.

【Export Status 】

- Our products had exported to over 30 countries, our customers are mainly in the field of Wind power, Mining machinery, Shipbuilding industry,Valves, Pumps, Blowers,Compressors and Machine tools etc.

*If you need a quick quotation,

please provide detailed drawings of your product directly

Please also attach materials, dimensions, tolerances, surface treatment, and quantity to improve the speed and accuracy of our quotation.

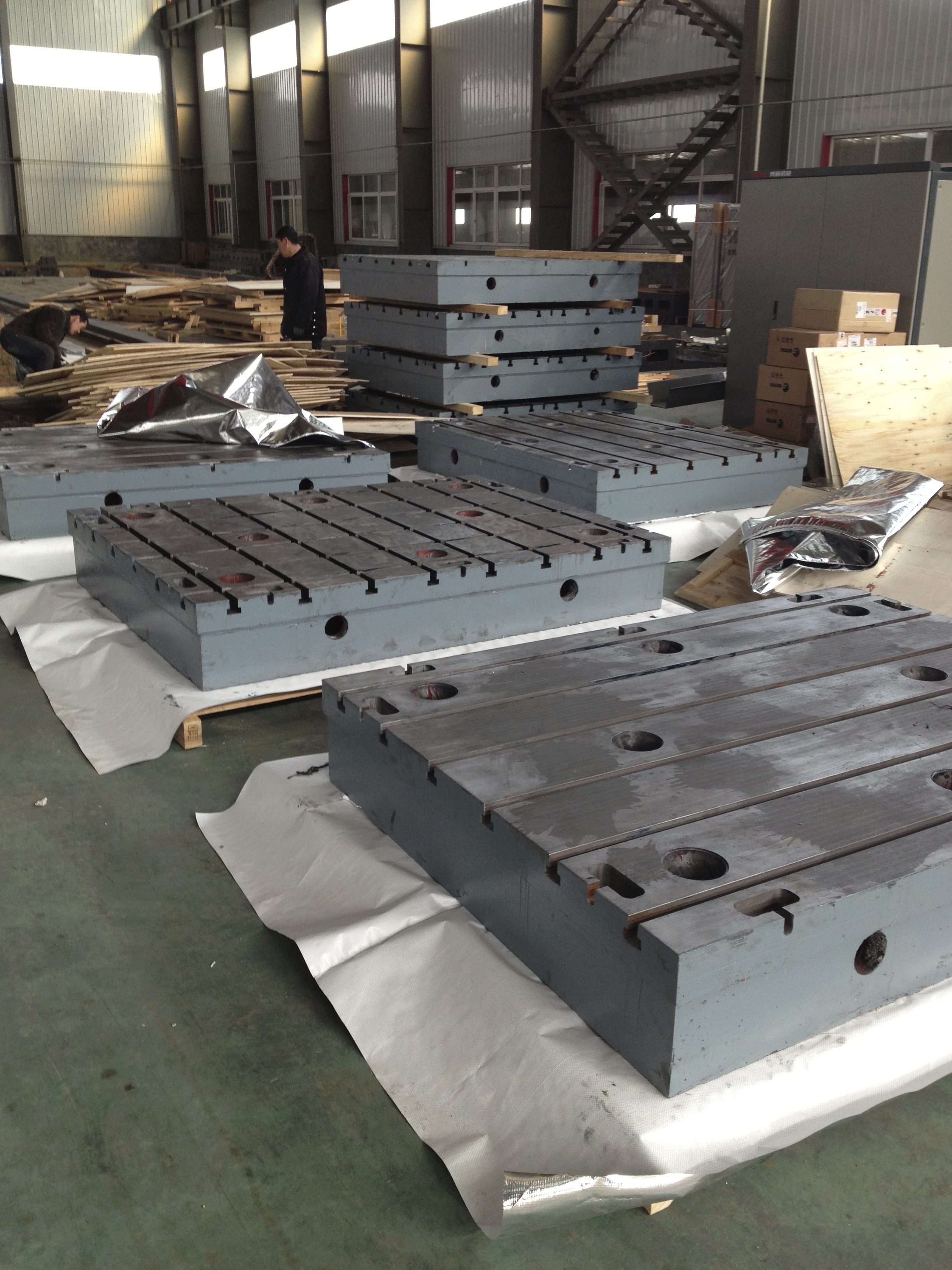

Main Equipment

|

L

ist-Casting

|

ITEM

|

SPECIFICATION

|

Q'ty

|

|

|

Furnace

|

Medium Frequency

Induction Furnace

|

15Ton

|

2Sets

|

|

|

|

Medium Frequency

Induction Furnace

|

25Ton

|

2Sets

|

|

|

Low pressure Casting Machine

|

|

3Ton

|

1Set

|

|

|

|

|

0.5Ton

|

1Set

|

|

|

Sand Mixer

|

Continuous Sand Mixer

|

20Ton/Hr

|

6Sets

|

|

|

Crane

|

O/H Crane

|

80Ton

|

3Sets

|

|

|

|

O/H Crane

|

10-50Ton

|

10Sets

|

|

|

|

Crane

|

10Ton

|

10Sets

|

|

|

Post Treatment

|

Shot Blasting

|

8*6*5.5m

|

1set

|

|

|

|

Coating & Drying Machine

|

8*6.2*6.5m

|

1set

|

|

|

|

Heat treatment

|

20T

|

1set

|

|

|

List-Machining

|

SPECIFICATION

|

Q'ty

|

Q'ty

|

|

|

CNC vertical lathe

|

DVT500×31/32Q-NC

|

1

|

6

|

|

|

|

CK5280. 45/150

|

4

|

6

|

|

|

Low pressure Casting Machine

|

CK5280×50

|

1

|

|

|

|

CNC Boring- Milling Machine

|

TJK6916

|

9

|

11

|

|

|

Sand Mixer

|

W160HC

|

2

|

|

|

|

CNC Boring Machine

|

W250HCNC

|

2

|

7

|

|

|

|

W200HBNC

|

2

|

10Sets

|

|

|

|

FCW150

|

3

|

10Sets

|

|

|

CNC gantry machining center

|

TK4225-600

|

1

|

2

|

|

|

|

THA57400-800

|

1

|

1set

|

|

|

3×8 Gantry Milling Machine

|

XK2530/8

|

2

|

2

|

|

|

List-Testing

|

Origin

|

Q'ty

|

|

Spectrum Analysis Tester

|

France

|

1

|

|

Brinell hardness Tester

|

China

|

4

|

|

Metallographic Microscope

|

Japan

|

1

|

|

Intelligent sand strength machine

|

China

|

9

|

|

Universal impact test machine

|

China

|

2

|

|

Sulfur Analysis tester

|

Germany

|

2

|

|

Tensile Tester

|

Japan

|

2

|

|

UT Flaw Detector

|

USA

|

3

|

|

MT Flaw Detector

|

USA

|

3

|

Technical information

Laser tracker measuring

Three-Dimension Coordinate Surveying Machine

Laser tracker measuring

MAGMA simulatuion software

The technical design and development capability of ductile iron and aluminum alloy castings is in the high-level in the

largecasting field. Adopting advanced MAGMA simulation software in assisting process design, process of all the products in KSK

aresimulated before production.

largecasting field. Adopting advanced MAGMA simulation software in assisting process design, process of all the products in KSK

aresimulated before production.

3D Scanning

There are 21 R&D and technical engineers, i.e. 5 master degree in technology, 4 senior engineers,(including 1 getting national

allowance) KSK is capable of process design for iron castings of different materials with various complexity.

allowance) KSK is capable of process design for iron castings of different materials with various complexity.

Molding Capacity

SK have various pouring pits 8 and the maximum size is 20m×7.5m×4.5m, more than 3000 ton moulding flasks in various sizes .Equiped with 20 t/h sand mixer 6 sets. Using furan resin process.

machine castings by wood pattern

Molding-Assembling-Sealing-Pouring

machine castings by lost foam pattern

Molding-Assembling-Sealing-Pouring

Hot Searches