- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WOBO

-

Model Number:

-

WO-001

-

Type:

-

Insulation Material

-

Material:

-

Rubber-plastic, Diolefin polymers

-

Item name:

-

Low Temperature Rubber Foam Insulation Sheet

-

Color:

-

Black,Blue

-

Density:

-

65-85kg/m3

-

Thickness:

-

6-50mm

-

Applicable Temperature:

-

-200°C~+125°C

-

Thermal Conductivity:

-

0.030-0.038 W/m.k

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WOBO

-

Model Number:

-

WO-001

-

Type:

-

Insulation Material

-

Material:

-

Rubber-plastic, Diolefin polymers

-

Item name:

-

Low Temperature Rubber Foam Insulation Sheet

-

Color:

-

Black,Blue

-

Density:

-

65-85kg/m3

-

Thickness:

-

6-50mm

-

Applicable Temperature:

-

-200°C~+125°C

-

Thermal Conductivity:

-

0.030-0.038 W/m.k

-196℃ Ultra Low Temperature Insulation Sheet /Multi layer composite cryogenic foam insulation / Low temperature pipeline insulation materials

Product Description

Rubber-plastic thermal insulation material

is a soft high-grade thermal insulation and energy-saving material, which is made of nitrile rubber and polyvinyl chloride with excellent performance as the main raw materials, with various high-quality auxiliary materials and foamed by a special process, and does not contain chlorofluorocarbons. This product has excellent properties such as softness, bending resistance, cold resistance, heat resistance, flame retardant, waterproof, low thermal conductivity, shock absorption and sound absorption. It can be widely used in central air conditioning, construction, chemical industry, medicine,textile and other industries.

Performance Index

Note:

1.

The above specifications are common specifications. If you need special specifications, you can make them according to your requirements.

2.

The sheets and pipes are black. If you need special colors, we can make them according to your requirements.

3.

It is recommended to use plates when the pipe outer diameter exceeds 89mm.

4

. The thickness of thermal insulation material needs to be more than 25mm, and it should be packed in multiple layers until the required thickness.

Product Features

No need for built-in expansion joints

WOBO flexible ultra-low temperature insulation system does not need to use fiber materials as fillers for expansion and contraction. On the contrary, it is only necessary to install each layer of low temperature elastomer materials with pressure ,according to the recommended reserved length to solve the expansion joint problem required by the traditional system.

Temperature range -200℃ to +125℃

The most economical and reliable cold insulation system, multi-layer composite structure, overcomes the stress at low temperature and provides maximum mechanical properties. It has low thermal conductivity and good insulation effect under the condition of low temperature and deep cooling, and the oxygen index is as high as 32 or more. Used for cold insulation with temperature as low as -200℃.

It can still keep elasticity at ultra-low temperature.

WOBO ultra-low temperature cold insulation products have the characteristics of low thermal conductivity, light weight and elasticity at low temperature. The unique color of this product is easy to identify and install. In some occasions, it can be constructed with cold without stopping, greatly reducing joints to ensure the air tightness of the system and improve the construction speed. There is no fiber and dust.

No need of built-in moisture-proof and steam-proof layer

WOBO low temperature insulation system does not need to install moisture barrier. Thanks to the unique closed-cell structure and polymer mixed formula, NBR elastic foam material has a high water vapor permeability resistance. This foaming material can make the product have continuous water vapor permeation resistance in the whole thickness direction.

Other Advantages and features

* Excellent thermal insulation performance-very low thermal conductivity

*

Seismic resistance-the ability to absorb pipeline vibration and external impact.

* Lower temperature variability than traditional rigid insulation

* More durable and low maintenance rate.

* Non-corrosive and durable

*

Good deformation resistance.

* ASTM/SGS/BS476/UL/GB certification

.

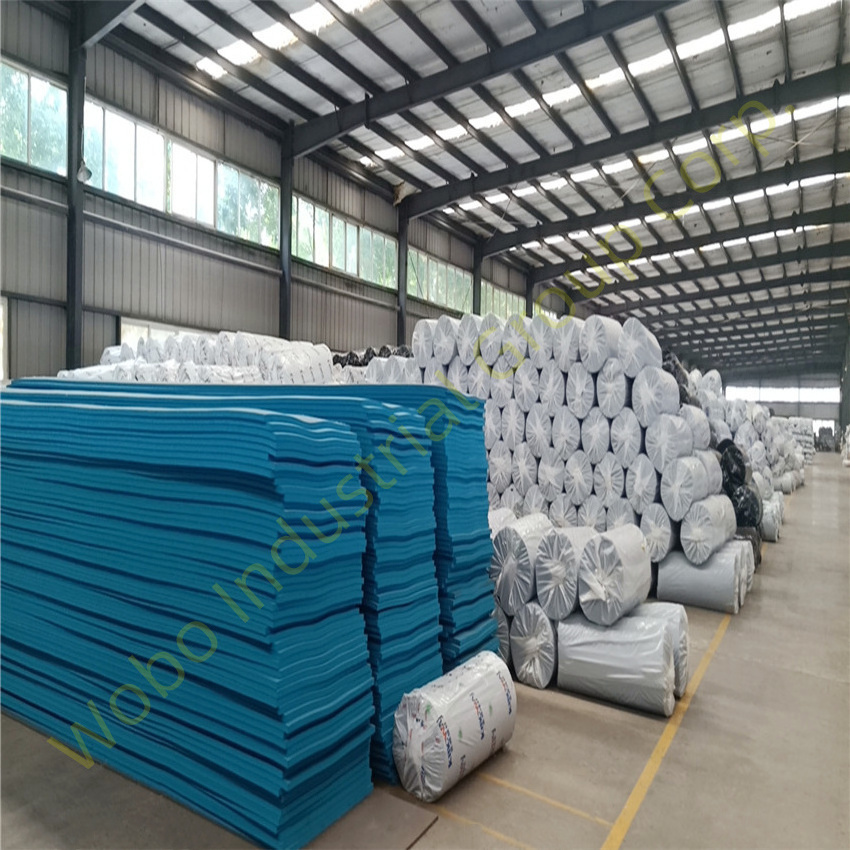

Product Show

Diolefins

,

Nitrile rubber

Ultra-low Temperature Insulation System is a high-performance diene elastic foam specially developed by

WOBO

for thermal insulation engineering under ultra-low temperature conditions. Our company's ultra-low temperature insulation system has the inherent characteristics of shock resistance, and its low temperature elastomer material can absorb he energy of external mechanical impact and vibration to protect the system structure. The impact force from any part can be widely dispersed and attenuated by the elastomer material, so as to avoid the cracking risk caused by stress concentration like the rigid foam insulation material. Reducing temperature stress is one of the important features of this cold insulation system,which is superior to traditional rigid foam insulation materials such as foam glass, polyurethane PIR and PUR. These traditional hard materials have no elasticity at normal temperature and low temperature, so there is a general phenomenon that the thermal insulation structure is damaged under external force and the thermal insulation performance is reduced due to extrusion cracking of the materials under temperature-varying stress.

Applications

The flexible ultra-low temperature insulation material is a closed-cell elastomer insulation material, which has excellent

properties such as softness, cold resistance, heat resistance, flame retardance, water resistance, low thermal conductivity, shock absorption and sound absorption. It can be widely used in various cold and hot medium pipelines and containers in industries and departments such as construction, chemical industry, medicine, metallurgy, ships, vehicles, etc., and can achieve the effect of reducing cold loss and heat loss. Because of its convenient construction, neat and beautiful appearance, and no pollution, it is a high-quality cross-century new generation thermal insulation material.

properties such as softness, cold resistance, heat resistance, flame retardance, water resistance, low thermal conductivity, shock absorption and sound absorption. It can be widely used in various cold and hot medium pipelines and containers in industries and departments such as construction, chemical industry, medicine, metallurgy, ships, vehicles, etc., and can achieve the effect of reducing cold loss and heat loss. Because of its convenient construction, neat and beautiful appearance, and no pollution, it is a high-quality cross-century new generation thermal insulation material.

Project Case

Hot Searches