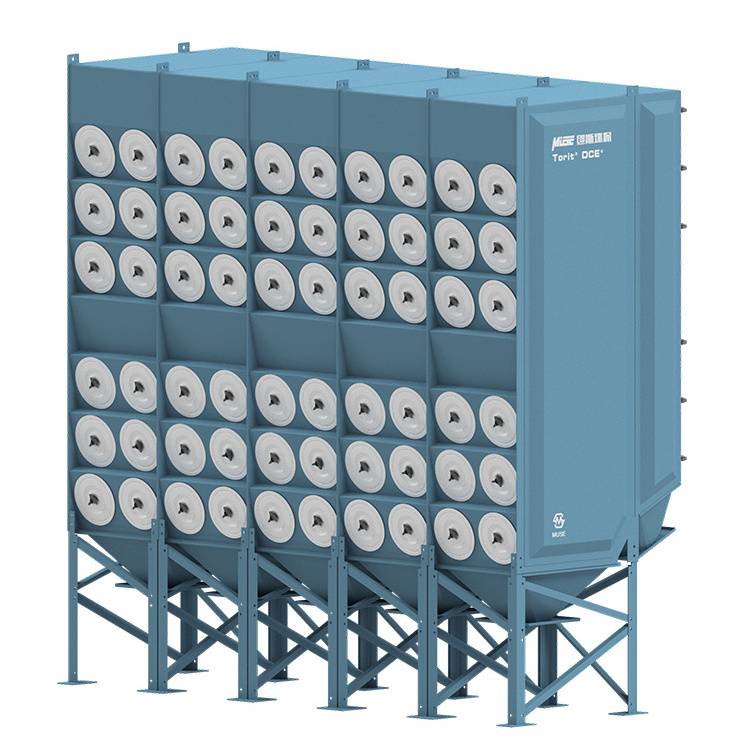

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1000 kg

-

Condition:

-

NEW

-

Colour:

-

Customizable

Quick Details

-

Marketing Type:

-

New Product 2023, New Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MUSE, MUSE

-

Weight:

-

1000 kg

-

Condition:

-

NEW

-

Colour:

-

Customizable

Hot Searches