- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Application:

-

for making types of plastic shopping bags, garbage bags, fruit bags

-

Bag raw materials:

-

LDPE, HDPE roll film

-

Sealing and cutting type:

-

heat sealing, cold cutting

-

Machine structure:

-

2 layers, 4 feeding rollers

-

Sealing and cutting::

-

heat sealing, heat cutting

-

Max. Bag making width:

-

580mm to 1180mm, can be customized.

-

Bag making speed:

-

40-400pcs/min

-

Control system:

-

Micro computer control

-

Driving system:

-

step motor or servo motor, frequency inverter control

Quick Details

-

Machine Type:

-

SEALING MACHINE

-

Bag Type:

-

Shopping Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Application:

-

for making types of plastic shopping bags, garbage bags, fruit bags

-

Bag raw materials:

-

LDPE, HDPE roll film

-

Sealing and cutting type:

-

heat sealing, cold cutting

-

Machine structure:

-

2 layers, 4 feeding rollers

-

Sealing and cutting::

-

heat sealing, heat cutting

-

Max. Bag making width:

-

580mm to 1180mm, can be customized.

-

Bag making speed:

-

40-400pcs/min

-

Control system:

-

Micro computer control

-

Driving system:

-

step motor or servo motor, frequency inverter control

(1) Efficient and satisfied service

(2) Complete machines solution for the whole production line

(3) Various and multi solutions for different requirement

(4) More than 18-year professional experience

(5) Qualified product and strict quality control

(6) ODM,OEM is welcome

We had the honor to serve many customers from more than 100 countries and regions.

Welcome to be one of our top “VIP” customers.

We believe that “The quality is the soul of an enterprise”.

“With us your MONEY in SAFE; Your BUSINESS in SAFE”.

Main Features

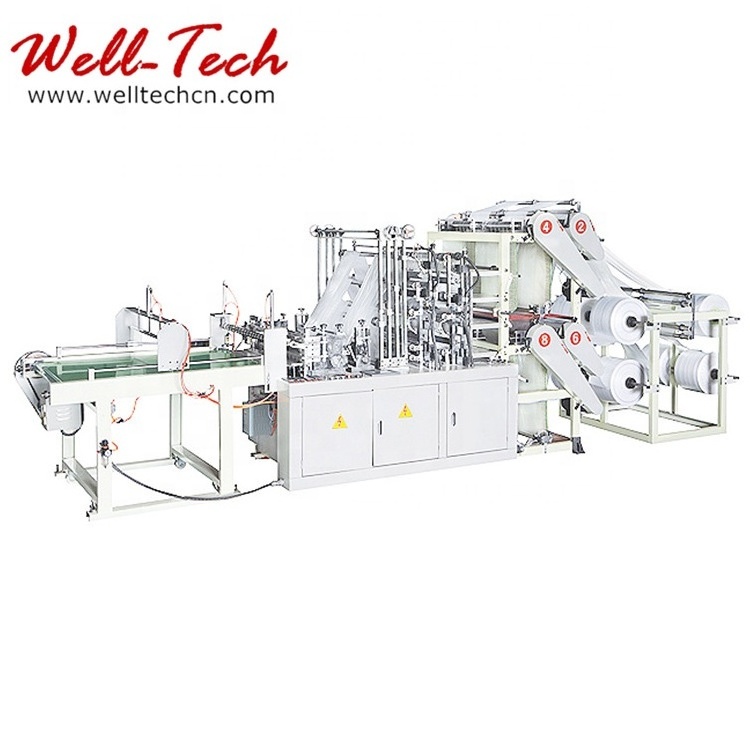

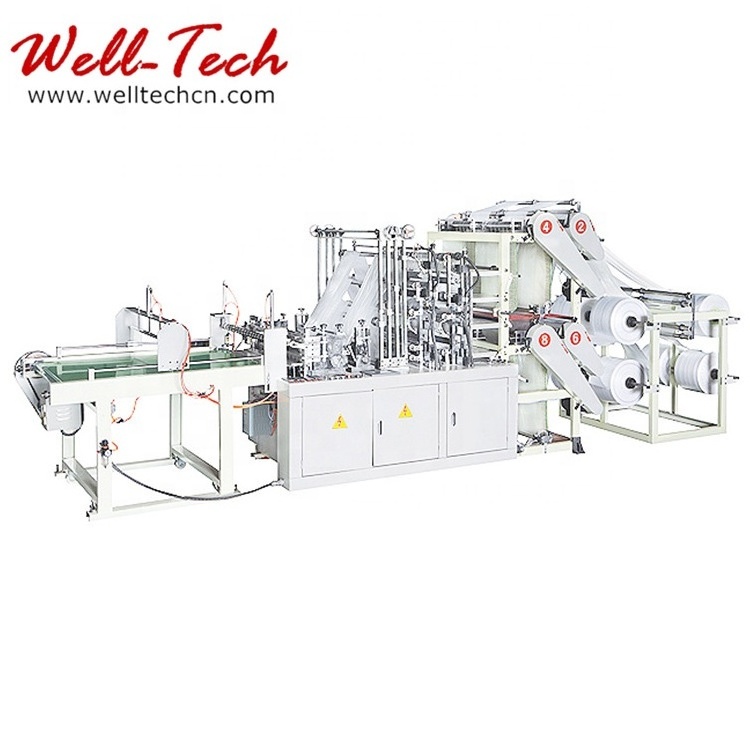

It is used for producing vest bags and flat-opening LDPE HDPE bags with printing. The main motor adopts frequency conversion motor to save more electricity and regulate speed more freely. The color code tracker with good performance makes the sealing and cutting length more accurate and the error smaller. It adopts advanced computer to adjust length more freely and accurately.

It can make one printed bag and three unprinted bags one time, or four unprinted bags one time in allowed width.

|

Model

|

WTLQ-2L600

|

WTLQ-2L700

|

WTLQ-2L800

|

WTLQ-2L1000

|

|||

|

Width of Sealing &Cutting(mm)

|

550

|

650

|

750

|

950

|

|||

|

Max. Length of Sealing & Cutting(mm)

|

1200

|

1500

|

2000

|

2000

|

|||

|

Speed of Bag-making (pc/min)

|

60-120 per line

|

|

|

|

|||

|

Number of Strip(pc)

|

2/4

|

|

|

|

|||

|

Power of Motor(kw)

|

1.1

|

1.5

|

1.5

|

3

|

|||

|

Weight(kg)

|

700

|

850

|

900

|

1100

|

|||

|

Overall Dimension(L x w x h)mm

|

3200×1200×1700

|

3500×1300×1850

|

3600×1500×1950

|

3800×1800×2100

|

|||

Complete Plastic Bag Production Line

The Complete Plastic Polythene Bags Production Line Machines including Film Blowing Machine, Printing Machine, Plastic Bag Making Machine, and Plastic Recycling Machines can be supplied. Multi solutions for the project of plastic bags production!