- Product Details

- {{item.text}}

Quick Details

-

Printing material:

-

Plastic Film

-

Machine Type:

-

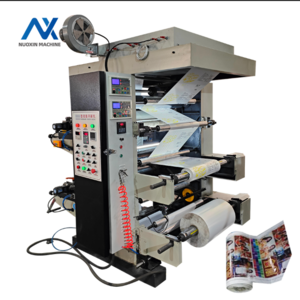

FlexoPrinting Machine

-

Color:

-

Accept Customized Color

-

Plate Thickness:

-

1-7mm

-

Printing colors:

-

1 - 6 Colors

-

Suitable material:

-

carton box

-

Related machine:

-

1.2.3.5 Colors Printing Machine

-

Printing speed:

-

1500-3500pcs/h

Quick Details

-

Place of Origin:

-

Hebei, China

-

Product name:

-

1 color flexo printing machine and slotter

-

Application:

-

Flexible Package Printing

-

Printing material:

-

Plastic Film

-

Machine Type:

-

FlexoPrinting Machine

-

Color:

-

Accept Customized Color

-

Plate Thickness:

-

1-7mm

-

Printing colors:

-

1 - 6 Colors

-

Suitable material:

-

carton box

-

Related machine:

-

1.2.3.5 Colors Printing Machine

-

Printing speed:

-

1500-3500pcs/h

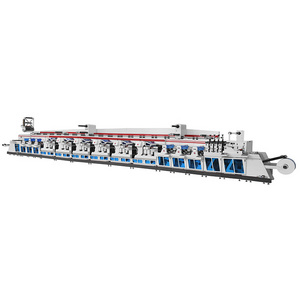

Huali hot sale 1 color flexo printing machine and slotter

1. The whole machine is adopted international famous brand appliances “Siemens, S chneider”.The quality is stable and reliable.

2. The machine shaft, roller are adopted high quality steel, grinding processing, high precision computer dynamic balancing correction and surface hard chromium plating.

3. The engine drive gear is adopted 4 0Cr , the shaving machining nitrogen treatment , tinted with high precision.

4. Machine transmission parts (shaft, gear joint) is adopted free key connection (LOCK-ALX),clears the connection gap.It is suitable for long-term high speed running with high torque.

5. The machine drive bearing ,important driving parts adopt three big domestic famous brand:Hava los,simple maintenance,long service life.

6. The engine lubrication system is adopted automatic spray type lubrication, equipped with auto oil level balance system.

7. It adopts Working gap adjustment, self-locking type worm wheel and worm gear device , quick performance and convenient adjustment.

8. The main motor is adopted frequency conversion control.It makes start, running more steadily and saves more energy .

9. Rotary die-cutting department and rotary slotting department is optional for you .

10.

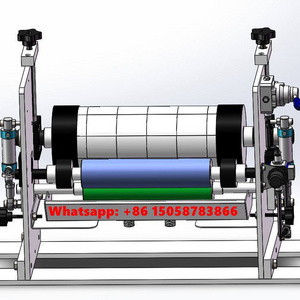

Option : ceramic anilox roller .stacking ,.

The Machine technical Parameter

|

1 |

Color group |

to be configured a ccording to user’ s needs |

||

|

2 |

Printing paper |

A,B,C,A/B,B/C and A/B/C type corrugated paperboard(the maximum interval 11mm) |

||

|

3 |

Width of machine inside |

2600 mm |

2800 mm |

3000mm |

|

4 |

max.paper size |

1200 × 2400 mm |

1400 × 2600 mm |

1600 × 2800mm |

|

5 |

Max.printing size |

1200 × 2300 mm |

1400 × 2500 mm |

1600 × 2600mm |

|

6 |

Skip feeding paper |

1400 × 2400 mm |

1600 × 2600 |

1800 × 2800 |

|

7 |

Min.paper size positive knife negative knife |

350 × 72 0 mm 350 × 7 4 0 mm |

400 × 72 0 mm 400 × 7 4 0 mm |

4 5 0 × 72 0 mm 4 5 0 × 7 4 0 mm |

|

8 |

Printing plate thickness |

7.2 mm |

7.2 mm |

7.2mm |

|

9 |

Design speed( piece/min) |

180pcs/min |

150pcs/min |

150pcs/min |

|

10 |

Economic speed(piece/min) |

80-1 6 0 pcs/min |

80-1 3 0 pcs/min |

80-100pcs/min |

|

11 |

Tinted precision |

4 ( color ) ± 0.5 mm |

4 ( color ) ± 0.5 mm |

4 ( color ) ± 0.5 mm |

|

12 |

Slotting precision |

± 1.5 mm |

± 1.5 mm |

± 1.5 mm |

|

13 |

Max.slotting depth |

7 × 300 mm |

7 × 350 mm |

7 × 40 0 mm |

|

|

|

increase the blade, increase the slot depth |

||

|

14 |

Min. Slot distance positive knife negative knife

|

1 7 0 × 1 7 0 × 1 7 0 × 1 7 0 mm 280 × 8 0 × 280 × 8 0 mm |

1 7 0 × 1 7 0 × 1 7 0 × 1 7 0 mm 280 × 8 0 × 280 × 8 0 mm |

1 7 0 × 1 7 0 × 1 7 0 × 1 7 0 mm 260 × 9 0 × 280 × 8 0 mm |

|

15 |

Max.die-cutting size |

1200 × 23 0 0 mmmm |

1400 × 25 0 0 mm |

1 6 00 × 2 70 0 mm |

|

16 |

Printing plate diameter(contain plate thickness) |

405 mm |

480 mm |

530mm |