- Product Details

- {{item.text}}

Quick Details

-

Type Spacification:

-

≤50mm

-

Substrate Size:

-

≥0.03mm

-

Copper Content of Substrate:

-

≥99.95%

-

Substrate Resistivity:

-

≤0.01724Ω.mm2 /m

-

Fusion Point:

-

186℃

-

Coating:

-

Sn60/Pb40

-

Single-sided Coating:

-

5±2μm

-

Thickness Tolerance:

-

±0.002mm

-

Width Tolerance:

-

±0.05mm

-

Elongation:

-

≥10%

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

NUUKO

-

Model Number:

-

NUKB01

-

Type Spacification:

-

≤50mm

-

Substrate Size:

-

≥0.03mm

-

Copper Content of Substrate:

-

≥99.95%

-

Substrate Resistivity:

-

≤0.01724Ω.mm2 /m

-

Fusion Point:

-

186℃

-

Coating:

-

Sn60/Pb40

-

Single-sided Coating:

-

5±2μm

-

Thickness Tolerance:

-

±0.002mm

-

Width Tolerance:

-

±0.05mm

-

Elongation:

-

≥10%

Product Description

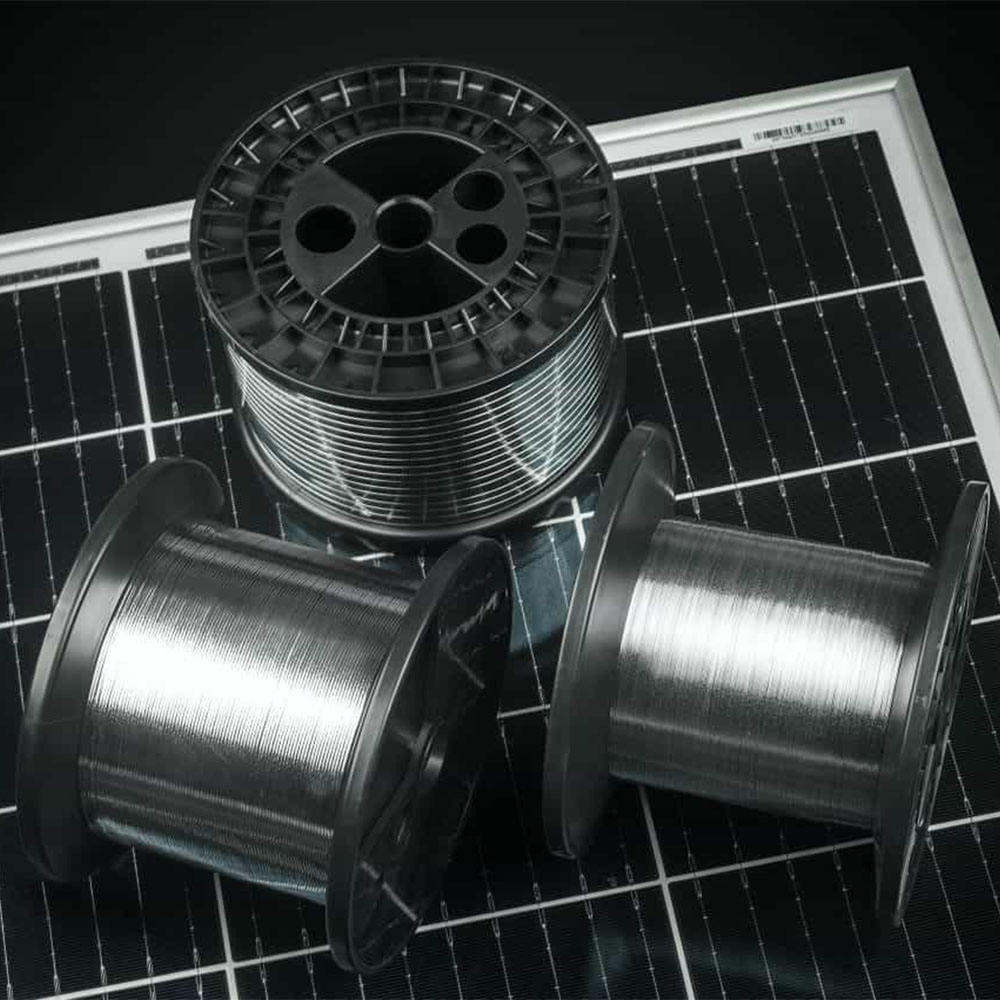

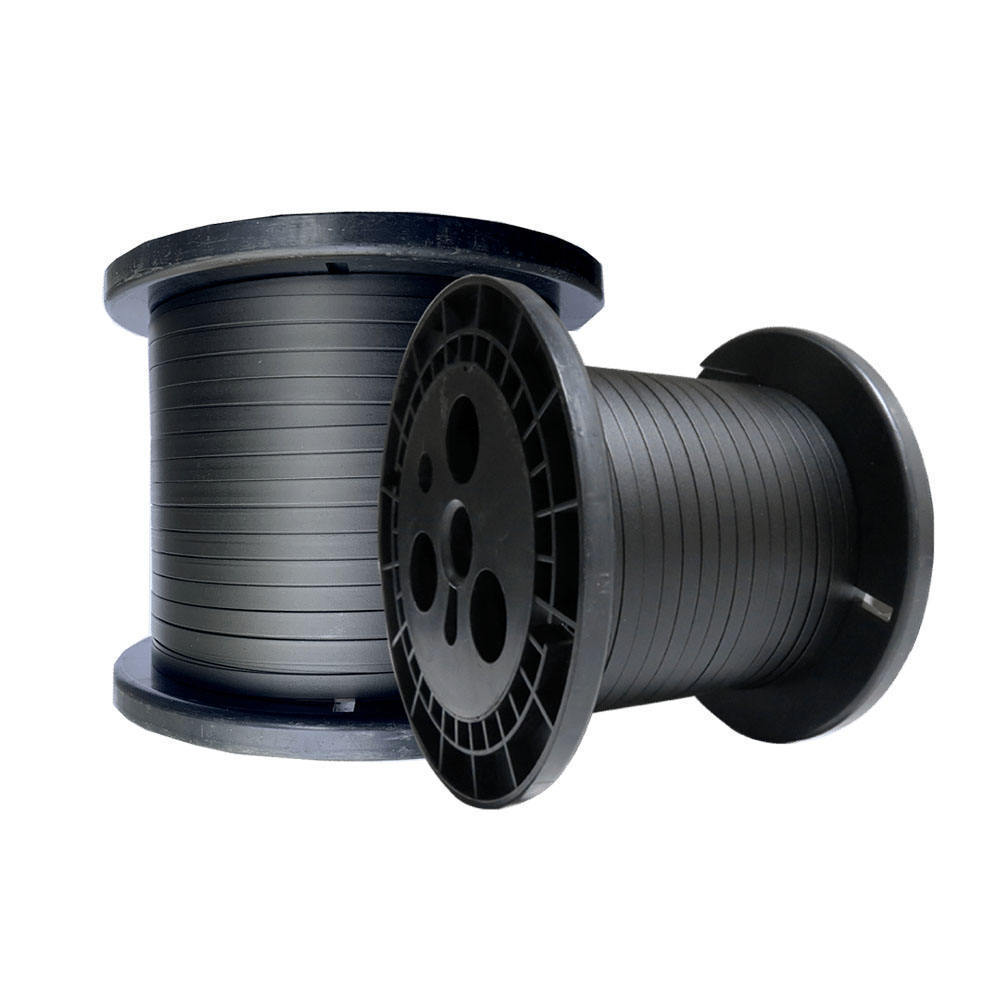

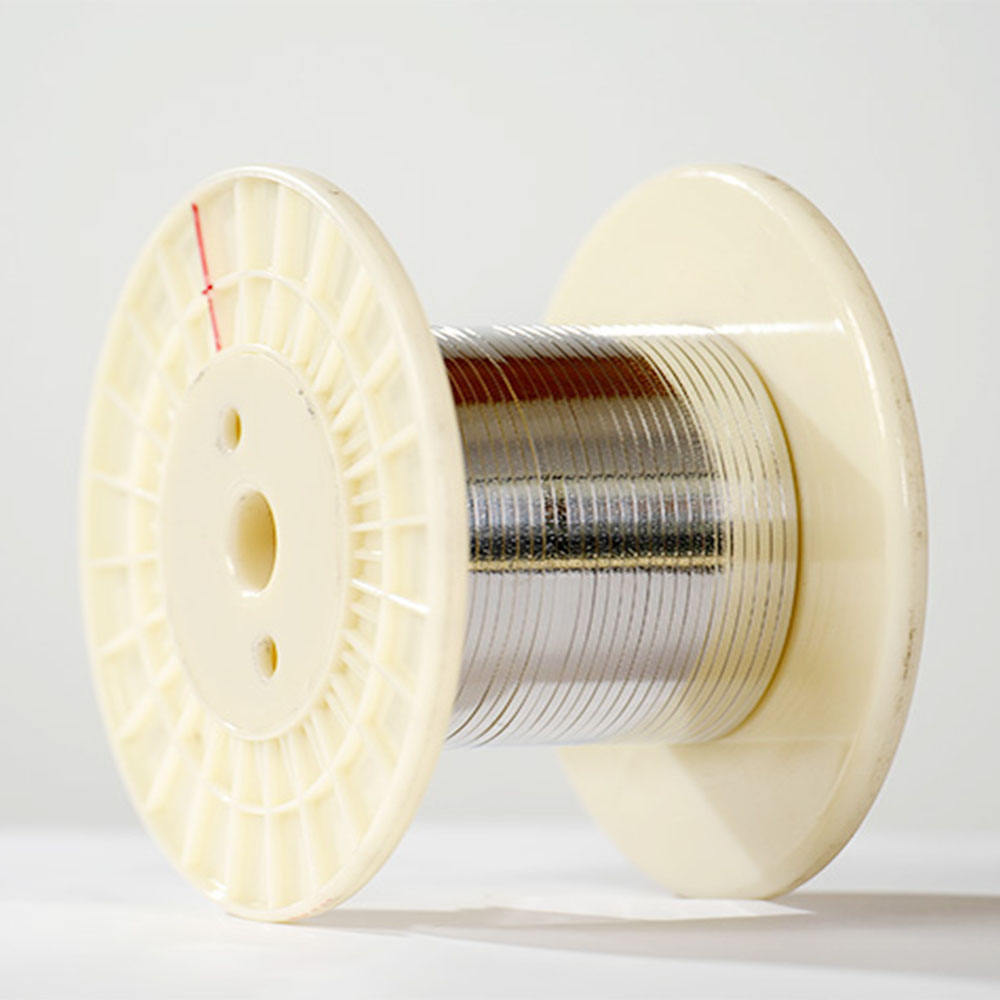

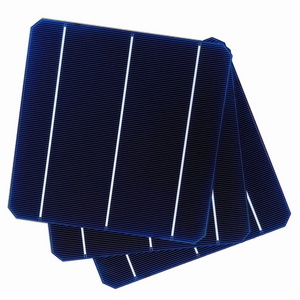

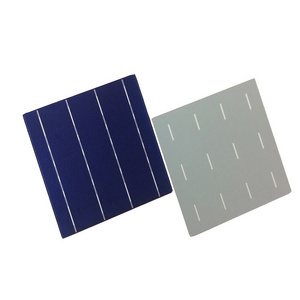

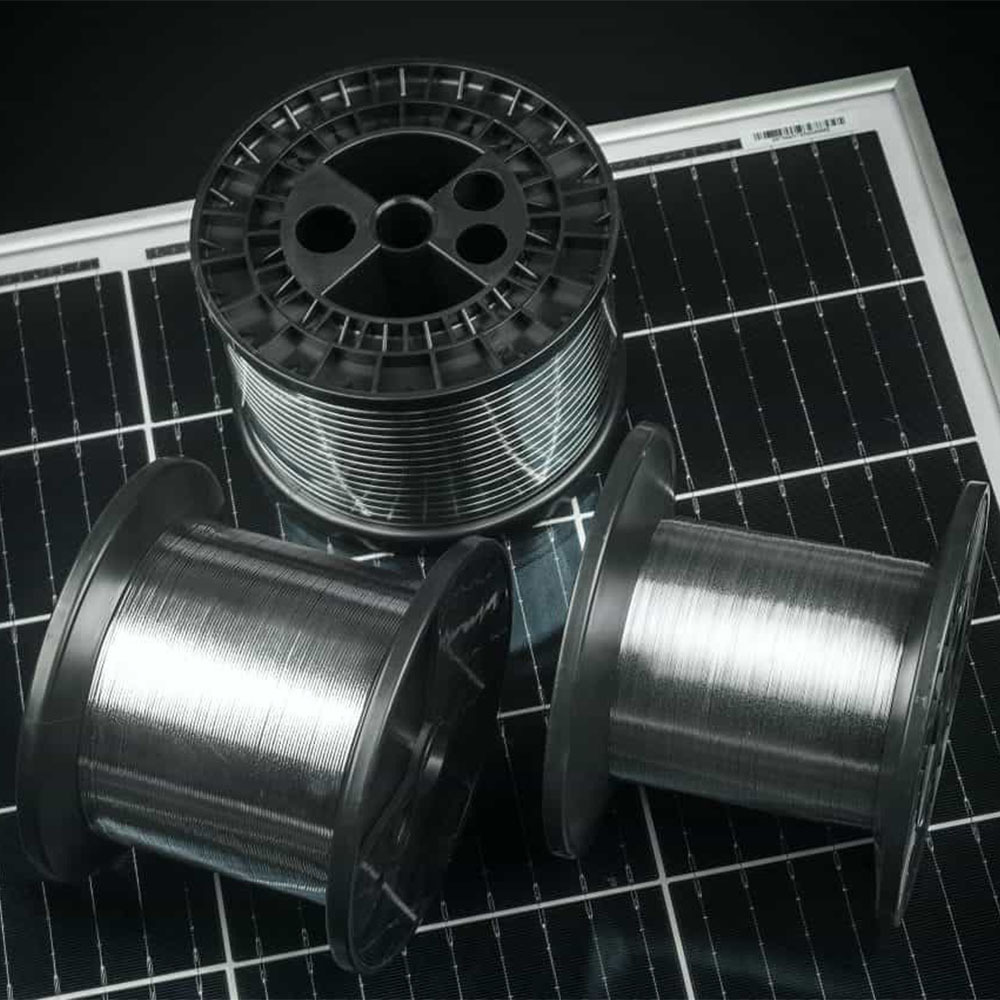

Photovoltaic soldering strips, also known as tinned copper strips or tin-coated copper strips, are divided into bus strips and interconnecting strips. They are used to connect photovoltaic modules and cells and play an important role in conducting electricity and collecting electricity.

Soldering ribbon is an important raw material in the welding process of photovoltaic modules. The quality of the soldering ribbon will directly affect the current collection efficiency of the photovoltaic module and has a great impact on the power of the photovoltaic module.

Application

Specification

|

Item

|

Value

|

|

Type Spacification

|

≤50mm

|

|

Substrate Size

|

≥0.03mm

|

|

Copper Content of Substrate

|

≥99.95%

|

|

Substrate Resistivity

|

≤0.01724Ω·mm² /m

|

|

Fusion Point

|

186℃

|

|

Coating

|

Sn60/Pb40

|

|

Single-sided Coating

|

5±2μm

|

|

Thickness Tolerance

|

±0.002mm

|

|

Width Tolerance

|

±0.05mm

|

|

Elongation

|

≥10%

|

|

Tensile Strength

|

≥100MPa

|

|

Sickle Bending

|

≤0.3%

|

|

Tabbing Ribbon Resistivity

|

≤0.023Ω·mm²/m

|

|

Storage Temperature

|

5-35℃

|

|

Storage Relative Humidity

|

≤60%

|

|

Warranty Period

|

6 months

|

|

Spool

|

Φ152-122-Φ20(φ16)mm -6kg

|

Packing & Delivery

At present, the most ideal metal element for developing low-temperature solder is bismuth, which can match various high-efficiency cells such as PERC, HJT, and IBC. Use solder with a melting point temperature lower than 180°C as raw material. Low-temperature welding can be achieved, which is beneficial to reducing the battery fragmentation rate. Other raw materials, product results and main production processes are consistent with conventional welding ribbons.

Hot Searches