- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fante

-

Voltage:

-

380V/50Hz/3Phase or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

Plastic Shredder Grinder Crusher Machine

-

Usage:

-

Rubber Shredding Waste Plastic Shredding

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic Crusher

-

Final product:

-

1-10 Cm

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Keyword:

-

Double Shaft Shredder

Quick Details

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

100 - 1000 kg/h

-

Brand Name:

-

Fante

-

Voltage:

-

380V/50Hz/3Phase or customized

-

Dimension(L*W*H):

-

See technical parameter

-

Power (kW):

-

3

-

Weight (T):

-

0.5

-

Application:

-

Recycle Waste Plastic

-

Name:

-

Plastic Shredder Grinder Crusher Machine

-

Usage:

-

Rubber Shredding Waste Plastic Shredding

-

Crushing material:

-

Types Waste Plastic

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Other name:

-

Double Shaft Plastic Crusher

-

Final product:

-

1-10 Cm

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Keyword:

-

Double Shaft Shredder

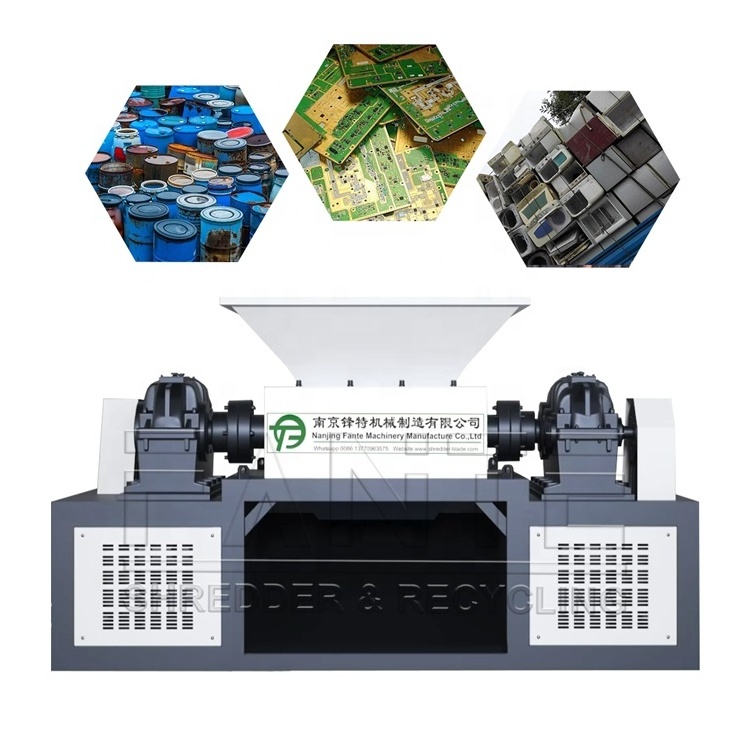

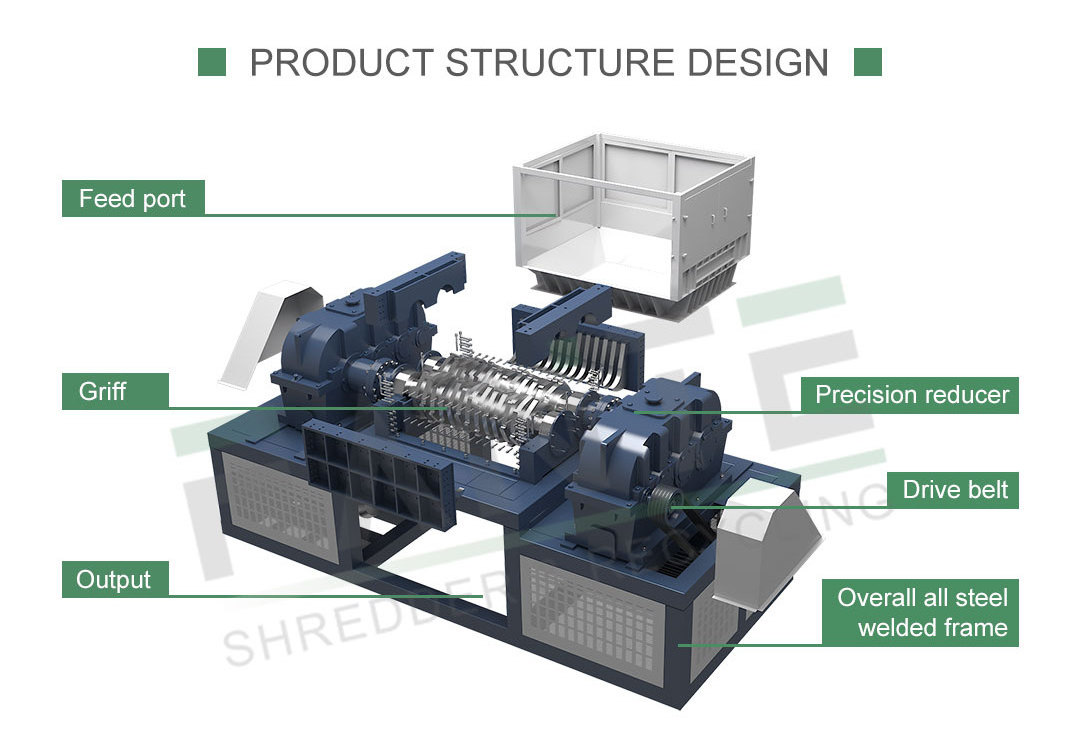

Our factory specializes in the production of heavy-duty industrial shredders and offers one-stop solutions for solid waste management. Our heavy-duty industrial shredders are designed to efficiently and effectively shred various types of materials, including but not limited to, plastics, rubber, wood, metal, and solid waste. With robust construction and powerful motors, our shredders can handle large volumes of waste and provide reliable performance.

Equipped with advanced shredding technology, our heavy-duty shredders ensure precise and consistent shredding results. The shredding process is controlled and optimized to achieve the desired output size and minimize the energy consumption. Our shredders are built to withstand the demands of heavy-duty applications and offer long-lasting durability.

In addition to their shredding capabilities, our heavy-duty industrial shredders also prioritize safety. They incorporate various safety features, such as emergency stop buttons, safety locks, and protective shields, to protect operators and prevent accidents.

With our one-stop solution for solid waste management, we provide customized system designs that integrate the shredders into the waste processing line. This includes feeding systems, sorting equipment, and waste conveyors, ensuring seamless integration and efficient operation.

Overall, our heavy-duty industrial shredders are the solution for businesses in need of effective and reliable waste management. Trust our expertise in providing high-quality shredding solutions that meet your specific requirements.

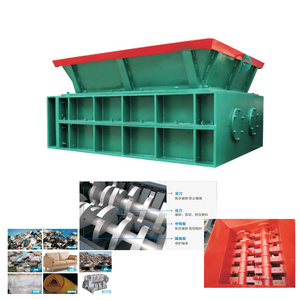

◼︎

The equipment is made up of two blades on two shafts that cut each other to meet the requirements of shredding materials. The size of the shredded material is related to the thickness and number of teeth of the shredded blade. The thinner the blade, the smaller the size of the shredded material. The more teeth the blade has, the shorter the length of the shredded material.

◼︎

The device adopts a low speed and high torque design, which has the characteristics of high shear force, good tearing effect, low noise, and good stability.

◼︎

Generally used for crushing soft materials, such as household waste, fabric scraps, household waste, fruit and vegetable waste, paper mill waste, medical waste, RDF fuel, etc.

|

Model

|

FTHS-600

|

FTHS-1000

|

FTHS-1200

|

FTHS-1600

|

FTHS-1800

|

FTHS-2000

|

|||||

|

power(kw)

|

11-15

|

30-75

|

37-150

|

150-264

|

150-220

|

150-500

|

|||||

|

Breaking chamber length(mm)

|

600

|

1000

|

1200

|

1600

|

1800

|

2000

|

|||||

|

Blade Size(mm)

|

⌀300-⌀800

|

|

|

|

|

|

|||||

|

Reducer

|

ZSY Or Planetary reducer

|

|

|

|

|

|

|||||

The chamber is processed as a whole, with small error, high accuracy, and reduced vibration and strain. Arc baffles are installed on both sides of the case to ensure smooth discharge and improve output.

It is made by multiple heat treatment and low temperature freezing heat treatment processes, with good overall toughness and hardness, ensuring cutting performance and service life. The fixed tool is installed by hook to optimize the tool replacement efficiency.

The bearing pedestal adopts the method of assembling and disassem-bling, which is convenient to remove the moving knife, fixed knife, bearing and other parts, easy to maintain and replace the tool, and the sealing structure is used to block the broken material, grease, liquid material, and protect the bearing and gear, etc. Self-aligning roller bearing is adopted.

PLC is programmed independently and equipped with start, stop, forward, reverse and overload protection functions. The overall automation ensures safety and stability and saves labor costs.

Hot Searches