- Product Details

- {{item.text}}

Quick Details

Quick Details

A compressed wood pallet machine line is an automated production system designed to manufacture high-quality, eco-friendly pallets made from compressed wood. These pallets are commonly used in various industries for storage, transportation, and logistics. The compressed wood pallet machine line typically involves several stages to process raw materials into finished pallets, all while maximizing efficiency and sustainability. Here's an introduction to the components and process:

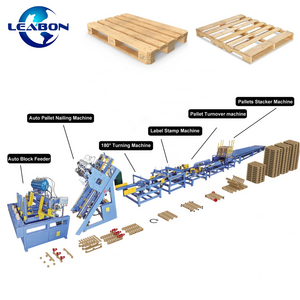

Key Components of a Compressed Wood Pallet Machine Line:

- Raw Material Preparation System:

- The raw material is usually wood waste, sawdust, wood chips, or wood shavings. These materials are first cleaned and prepared to ensure they are free from contaminants.

- The raw materials may be ground into smaller pieces (if necessary) before being fed into the machine.

- Mixing & Moisture Control:

- The raw wood particles are mixed with additives like resin or glue (in some cases) to bind the materials together.

- Moisture control is critical in this step to ensure the final product has optimal strength and durability. A proper moisture content also aids in the compaction process.

- Molding and Compression Machine:

- The heart of the machine line is the molding and compression unit. This machine takes the mixed material and compresses it into a pallet shape under high pressure and temperature.

- The compression process consolidates the wood particles into a dense, strong form that is suitable for use in pallet construction. The compressed pallets are shaped according to standard or custom specifications.

- Drying System (if needed):

- After compression, the pallets may still have a high moisture content. A drying system ensures that the pallets are dried to the correct level to prevent mold, mildew, and degradation over time.

- This could involve a drying chamber or an infrared dryer depending on the production scale.

- Cooling and Shaping:

- After the pallets are compressed and dried, they are cooled down to a stable temperature, after which they may undergo final shaping or trimming.

- The edges of the pallets are trimmed to give them a uniform appearance.

- Finishing and Quality Control:

- Pallets are inspected for quality, strength, and dimension accuracy.

- Some lines also offer options for branding or marking pallets (e.g., with logos or product information).

- Quality control ensures the pallets meet industry standards for load-bearing capacity, size, and durability.

- Pallet Stacking and Packaging:

- Once the pallets are finished, they are stacked and packaged for shipment. Some lines include automated systems to stack, wrap, and prepare the pallets for delivery.

Key Features and Benefits:

- Eco-Friendly: These pallets are made from recycled or waste wood, making them an environmentally friendly option for businesses. The use of compressed wood reduces deforestation and waste.

- Durability and Strength: Compressed wood pallets are strong and resistant to damage, offering a reliable solution for material handling.

- Customization: Pallets can be customized in terms of size, shape, and design to meet specific customer requirements.

- Cost-Effective: The process optimizes the use of raw materials and reduces production costs in comparison to traditional wooden pallets.

- Low Maintenance: Compressed wood pallets require less maintenance than standard wooden pallets, as they are less prone to splintering or damage.

- Lightweight: Compressed wood pallets can be lighter than conventional solid wood pallets, making them easier to handle and reducing shipping costs.

Applications:

- Logistics and Distribution: Compressed wood pallets are widely used in the transportation of goods due to their strength and ability to carry heavy loads.

- Warehousing: These pallets are often used for storing products in warehouses as they are reliable and can handle various types of products.

- Export and International Shipping: Since compressed wood pallets can be heat-treated or kiln-dried to meet international shipping standards (e.g., ISPM-15), they are ideal for global trade.

Conclusion:

A compressed wood pallet machine line is an innovative, efficient, and sustainable solution for producing high-quality pallets. It combines modern machinery and materials science to create a versatile and durable product that serves a wide range of industries. By using compressed wood, manufacturers can minimize waste, reduce environmental impact, and offer a cost-effective alternative to traditional wooden pallets.

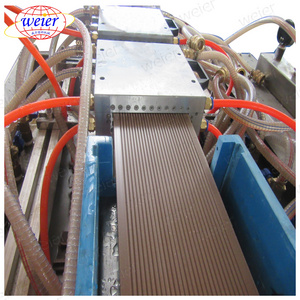

Material can be used in the production line

Manufacturing process:

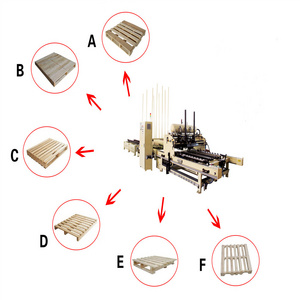

Various design of pallets available:

Hydraulic press machine available in different design.