- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless steel/Carbon steel/Alloy steel/Aluminium

-

Length:

-

1000mm, 1000mm

-

Place of Origin:

-

Suhzou, China

-

Brand Name:

-

WF

-

Product name:

-

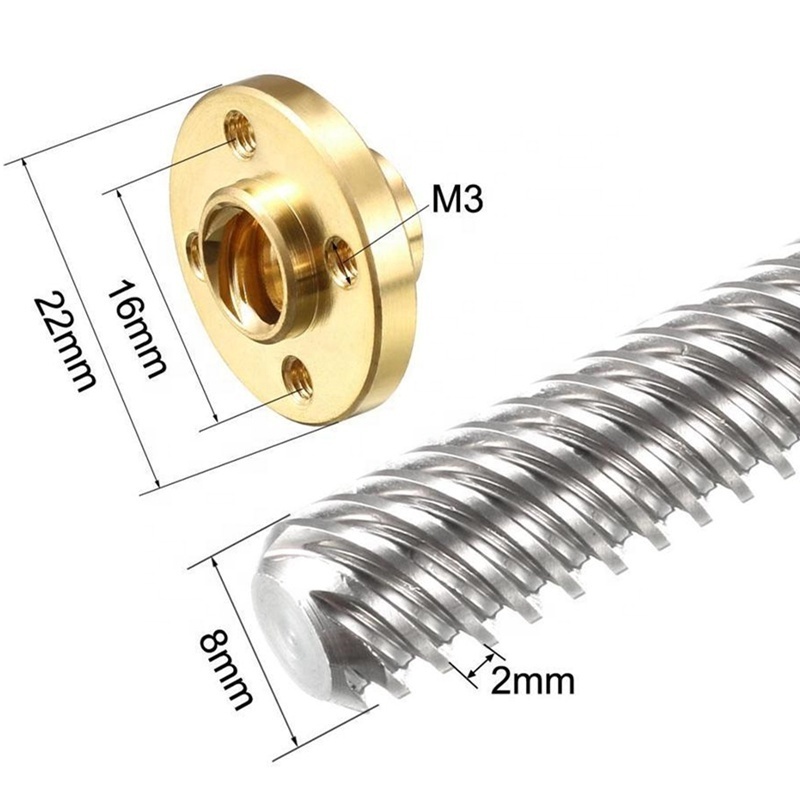

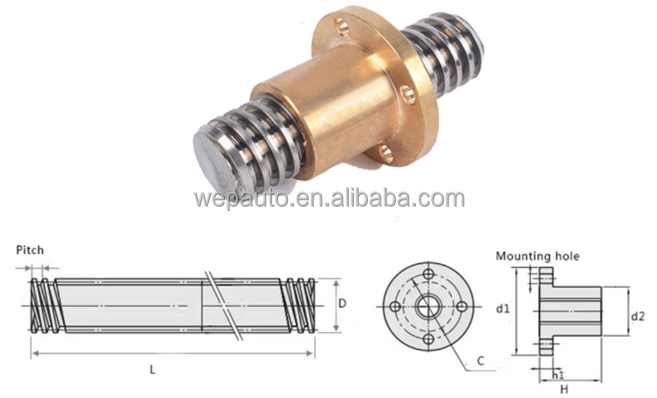

Tr10 Trapezoidal Screw

-

Pitch:

-

2mm

-

Lead:

-

2mm 4mm 8mm 10mm 12mm 14mm 16mm 20mm

-

Precision:

-

7e

-

Straightness:

-

0.15mm/meter

-

Process type:

-

Rolled thread/Milled Thread

-

Structure:

-

Trapezoidal Screw+Screw Nut

-

Nut type:

-

Single Nut

-

Nut Shape:

-

Round/Flange/Square

Quick Details

-

Weight (KG):

-

0.6

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

Screw Nut, Trapezoidal screw

-

Material:

-

Stainless steel/Carbon steel/Alloy steel/Aluminium

-

Length:

-

1000mm, 1000mm

-

Place of Origin:

-

Suhzou, China

-

Brand Name:

-

WF

-

Product name:

-

Tr10 Trapezoidal Screw

-

Pitch:

-

2mm

-

Lead:

-

2mm 4mm 8mm 10mm 12mm 14mm 16mm 20mm

-

Precision:

-

7e

-

Straightness:

-

0.15mm/meter

-

Process type:

-

Rolled thread/Milled Thread

-

Structure:

-

Trapezoidal Screw+Screw Nut

-

Nut type:

-

Single Nut

-

Nut Shape:

-

Round/Flange/Square

Products Description

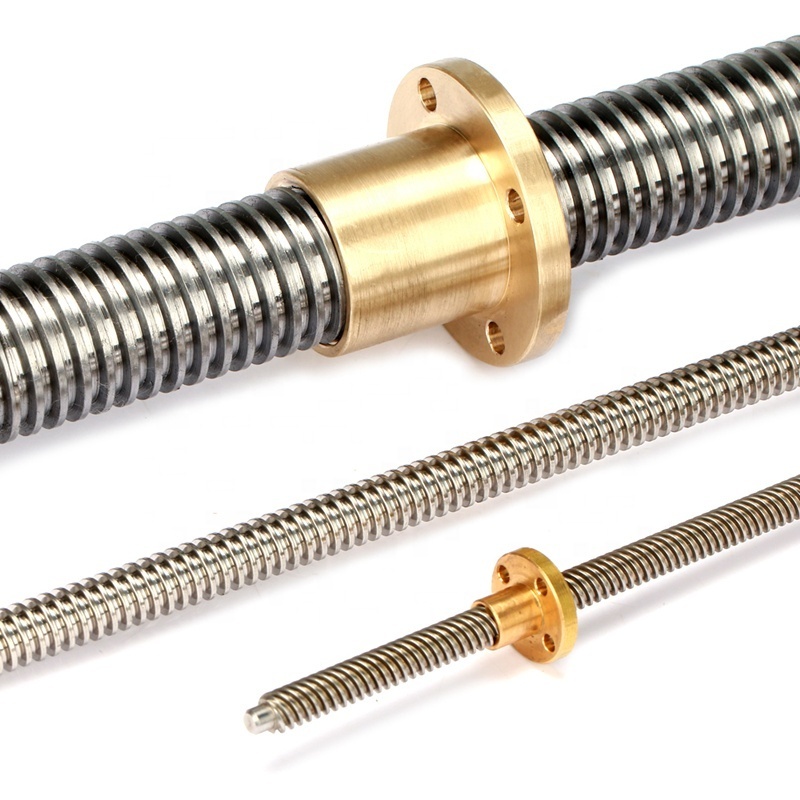

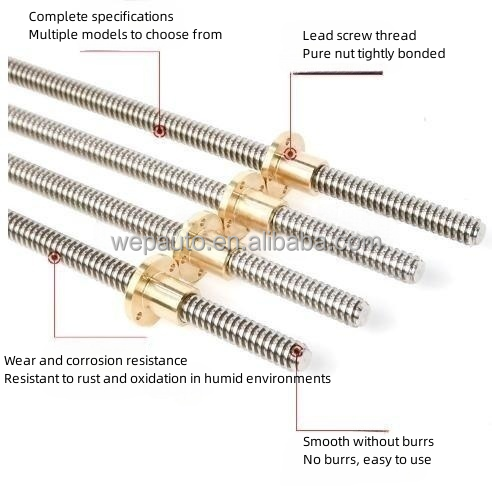

CNC T5 T6 T8 T10 T12 Stainless Steel Trapezoidal Threaded Rod Screw Self Reversing Lead Screw with Bronze Brass Nut

Trapezoidal lead screw is made of screw and T-nut. Its function is to turn the rotary motion into linear motion which is a future extension and development of ball screw. The significance of the development is to move into a rolling bearing from sliding action. With little frication, Trapezoidal Screws are widely used into various industrial equipment and precision instruments.

We produce all types of standard or non-standard trapezoidal lead screws and nuts according to customer's request.Detailed as following table:

|

Trapezoidal Screw Material

|

Stainless steel

|

Carbon steel

|

Alloy steel

|

Aluminium

|

|||

|

Screw Nuts Material

|

Stainless steel

|

Carbon steel

|

POM

|

Bronze/Brass/Copper

|

|||

|

Regular Size

|

TR5/6/8/10/12/14/16/18/20/22/25/28/30/32/36/40/45/50

|

|

|

|

|||

|

Thread Direction

|

Right

|

Left

|

Right and Left

|

|

|||

|

Manufacturing Process

|

Rolled Thread

|

Milled Thread

|

|

|

|||

|

Length

|

1000mm/Customized Length 100mm-3000mm

|

|

|

|

|||

|

End machining Customized

|

Provided

|

|

|

|

|||

|

Service

|

OEM Service

|

|

|

|

|||

Details Images

Product display

Product details and packing display

Recommend Products

Transaction History

Packing & Delivery

All products will be packde with standard export wooden case or cartons.Shafts packed with paper tube or plastic bag;Linear guideways or lead screws wrapped with film or plastic bag;guarantee well protected against dampness,moisture,rust and shock.

Shipping have many options:by sea or air or rail.A small amount can be sent by courier(DHL,FEDEX,TNT,UPS);Bulk quantities shipped by sea FCL or LCL.DDP also be accepted.

Workshop & Team & Customer

FAQ and Our Service

Q1:Are you a manufacturer?

Yes,we have been in manufacturing and providing excellent linear motion parts for customers more than 12 years.

Q2:How long could you prepare samples?

Ans:Normally 1 day if we have the sample onhand.If customized one.about a week aroud.

Q3:How about batch order production?

Ans:Normally 30 days or so for one container.

Q4:Do you inspect the finished products?

Ans:Yes,we will do inspection according to Ido standard and ruled by our QC staff.

Q5:How do you ship the goods?

Ans:By sea,by air by truck or by courier(UPSDHLFedexTNT etc.)

Q6:What advantage do you have?

1Ans:We have professional engineers,customers can expect the best possible advice and support.

2:Related responsible team to answer all your questions and follow-up process for you and do update in time.

3:Strict and standard process control according to Quality Management Syatem.

4:Documents support on products,we have strong technical data sheet to support our products,which could make you easier to know our products.

|

Service before sale

|

1.One-on-one exclusive customer service staff, 24 hours online.

2.Inquiry, email, message will be replied at first time. 3.Supply professional technical parameters, video picture sharing, project design. |

|

|

|

|||

|

Service on sale

|

1.Ensure customer payment security.

2.Ensure the customer's price is stable and reasonable. 3.Insist on quality first the production standard, every part before leave the factory we test it ensure the quality is good. |

|

|

|

|||

|

Service after sale

|

1.Arrange high-efficiency delivery and safe transport.

2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service. |

|

|

|

|||

Contact

Hot Searches