- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.01

-

Voltage:

-

220v

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dongtai

-

Dimension(L*W*H):

-

2100*1800*2300

-

Weight:

-

1300 KG

-

Product name:

-

piston bottle cooking oil/peanut oil/vegetable oil filling machine

-

Machine size:

-

2100*1800*2300

-

Measurement:

-

0.01

-

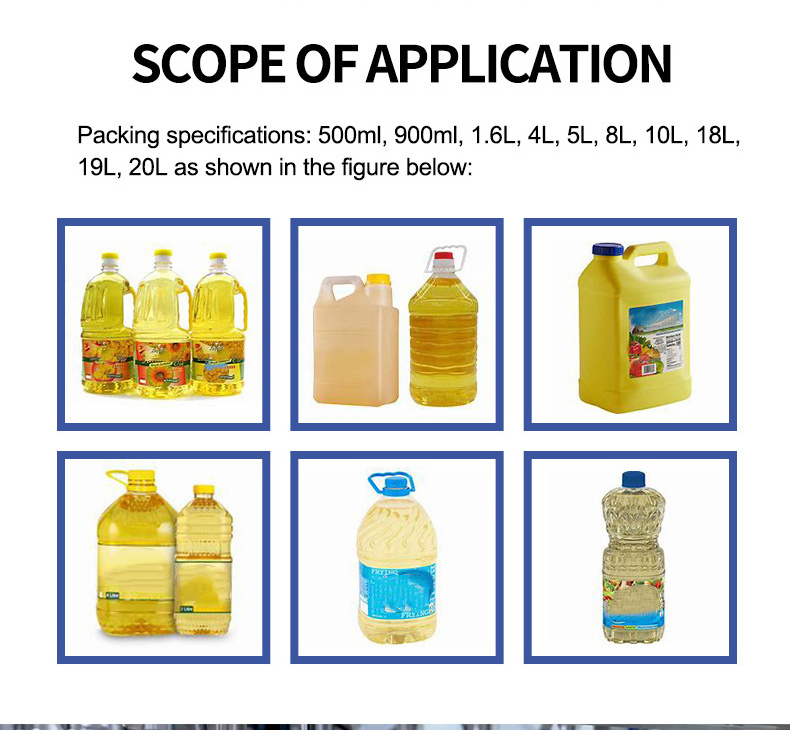

Packing specification:

-

10ml-30l

-

Equipped with power supply:

-

380V 50/60Hz

-

Host power:

-

2.5kw

-

Air pressure:

-

0.6-0.8MPa

-

Function:

-

Automatic Filler

-

Number of filling heads:

-

Support customization

Quick Details

-

Machinery Capacity:

-

20000BPH, 16000BPH, 500BPH, 2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Oil

-

Filling Accuracy:

-

0.01

-

Voltage:

-

220v

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dongtai

-

Dimension(L*W*H):

-

2100*1800*2300

-

Weight:

-

1300 KG

-

Product name:

-

piston bottle cooking oil/peanut oil/vegetable oil filling machine

-

Machine size:

-

2100*1800*2300

-

Measurement:

-

0.01

-

Packing specification:

-

10ml-30l

-

Equipped with power supply:

-

380V 50/60Hz

-

Host power:

-

2.5kw

-

Air pressure:

-

0.6-0.8MPa

-

Function:

-

Automatic Filler

-

Number of filling heads:

-

Support customization

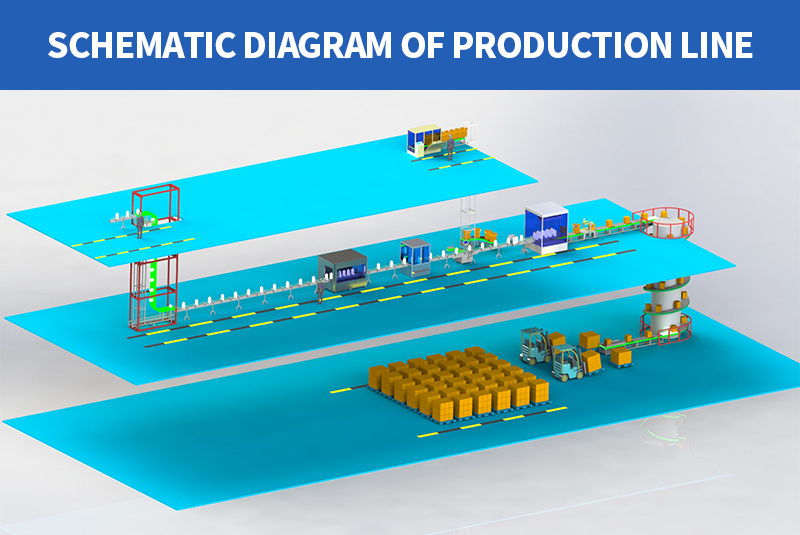

High-quality fast speed piston bottle cooking oil/peanut oil/vegetable oil filling machine

Product Description

The oil filling machine is suitable for quantitative small packaging filling, linear filling, electric and equipment control of various viscous, non-viscous, and corrosive liquids in the vegetable oil chemical, liquid, and daily chemical industries.

|

Filling head

|

2 heads

|

4-6 heads

|

8-10 heads

|

12 heads

|

|||

|

Filling efficiency (2L/hour)

|

500 bottles

|

600-800 bottles

|

1800-2500 bottles

|

3000-3500 bottles

|

|||

|

Quantitative error

|

±2 grams (when 500g)

|

|

|

10 Years Experiences

|

|||

|

Operating Voltage

|

380/220v (customizable) 50hz

|

|

|

|

|||

|

working pressure

|

0.6-0.8Mpa

|

|

|

|

|||

|

Capacity range

|

10-500ml 500ml-5L 5L-30L

|

|

|

3A

|

|||

|

Dimensions

|

800*1500*1600

|

1600*1600*2200

|

2100*1800*2300

|

2600*1800*2300

|

|||

Details Images

Single head single pump single frequency control, volume and quality two metering methods free conversion, convenient filling adjustment。

The filling machine adopts a configurable output system. You can set the output of each product in a single batch. For example, filling 1.6L cooking oil 1000 bottles. The filling machine can calculate the number of bottles by itself, and can realize the automatic shutdown after reaching the output. Realize real-time tracking of output

The capping machine is mainly suitable for pharmaceutical, food, chemical, daily chemical and other industries, is the ideal supporting equipment in the automatic production line. Especially for the bottle caps that require no wear, such as the printed caps that need to be produced or packaged in the next step, this equipment can also effectively reduce wear; Automatic capping, easy to operate; Bottle straight into, continuous capping, efficient and fast (capping speed is 2-3 times faster than general capping); It is suitable for automatic capping of various specifications of edible oil bottles.

Mainly applicable to food, grain, oil, industrial and other industries in the square, round bottle material fast automatic labeling requirements. (such as: flat bottle labeling, square bottle labeling, and production site matching edible oil labeling). It has the advantages of good universality, high stability and durability.

Powerful function, a machine can realize a variety of products of single-side and double-sided labeling (round bottle, flat bottle, square bottle) and integrate the circular surface labeling round bottle;

Equipment design and production in line with the production line process and layout requirements, beautiful appearance, good manufacturing technology; Low electricity and water consumption, simple and convenient operation, adjustment and maintenance; The machine has good self-safety protection functions, such as overload protection and safety door; There is no cardboard box alarm function; Storage mechanism: About 50 unformed cartons can be placed at one time (depending on carton thickness) and can be replenished at any time.

Recommended Products

Packing and shipping

Conventional raw material packaging

1. The surface is treated with rust prevention,

2. Inner plastic waterproof packaging,

3. Fix the outer layer with thick wood or steel frame, and then pack it with synthetic board. Combined container transportation, or separate container transportation.

transport:

1. The standard plywood box body has better compressive strength and bearing quality.

2. The board area is small, the soil structure is good, and the leakage and water resistance are good.

3. When imported, the plywood box is free of fumigation, and the operation is simple.

company certification

All of our filling machine is made of superior spare parts,the processing line assembled strictly according to ISO9001 regulation,so our equipment fully in accordance with the GMP&ISO standard production and passed CE certification.

Hot Searches