- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UBT

-

Service life:

-

Than15 Years

-

Operate way:

-

automatically

-

service:

-

after- sale service

-

Certification:

-

ISO CE

-

Name:

-

cooling system

Quick Details

-

Core Components:

-

PAD

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UBT

-

Model Number:

-

UBT

-

Service life:

-

Than15 Years

-

Operate way:

-

automatically

-

service:

-

after- sale service

-

Certification:

-

ISO CE

-

Name:

-

cooling system

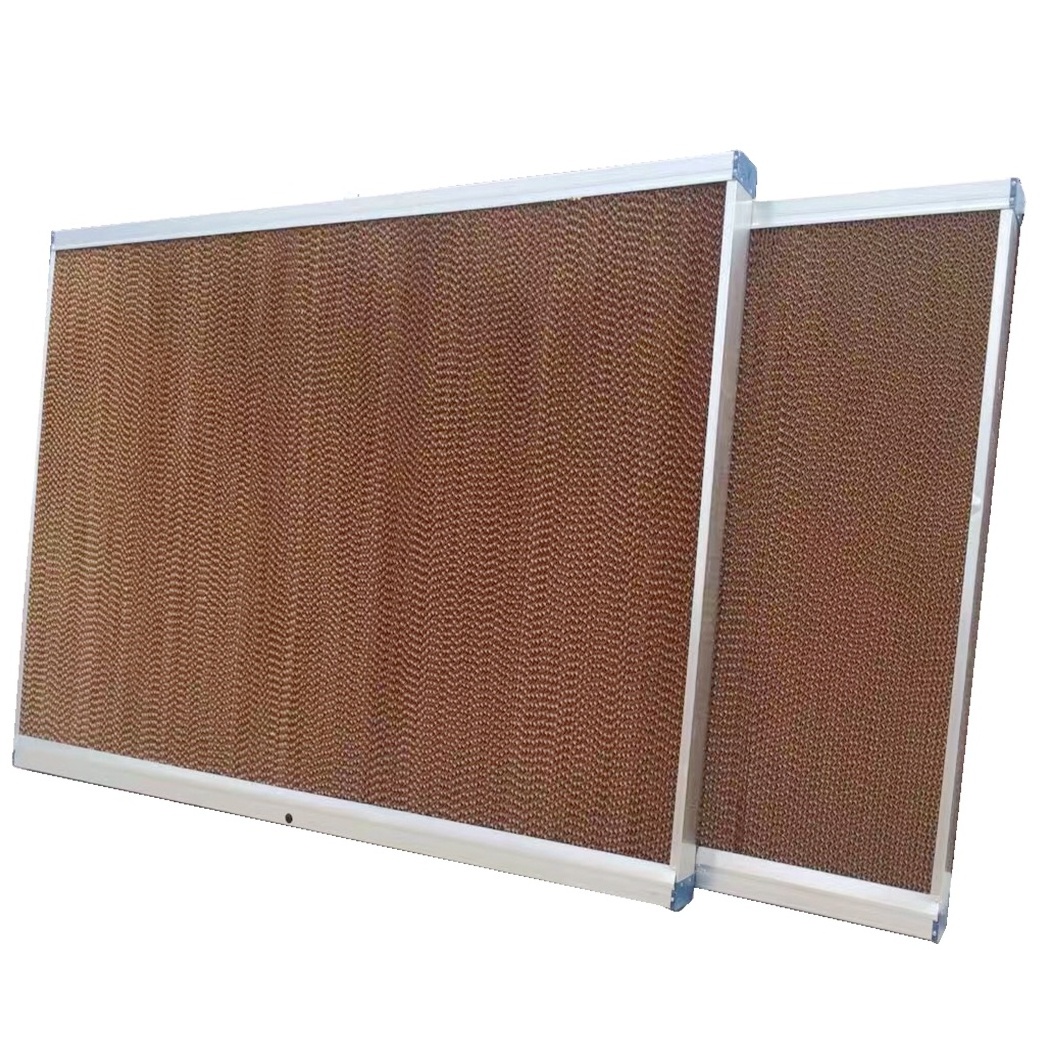

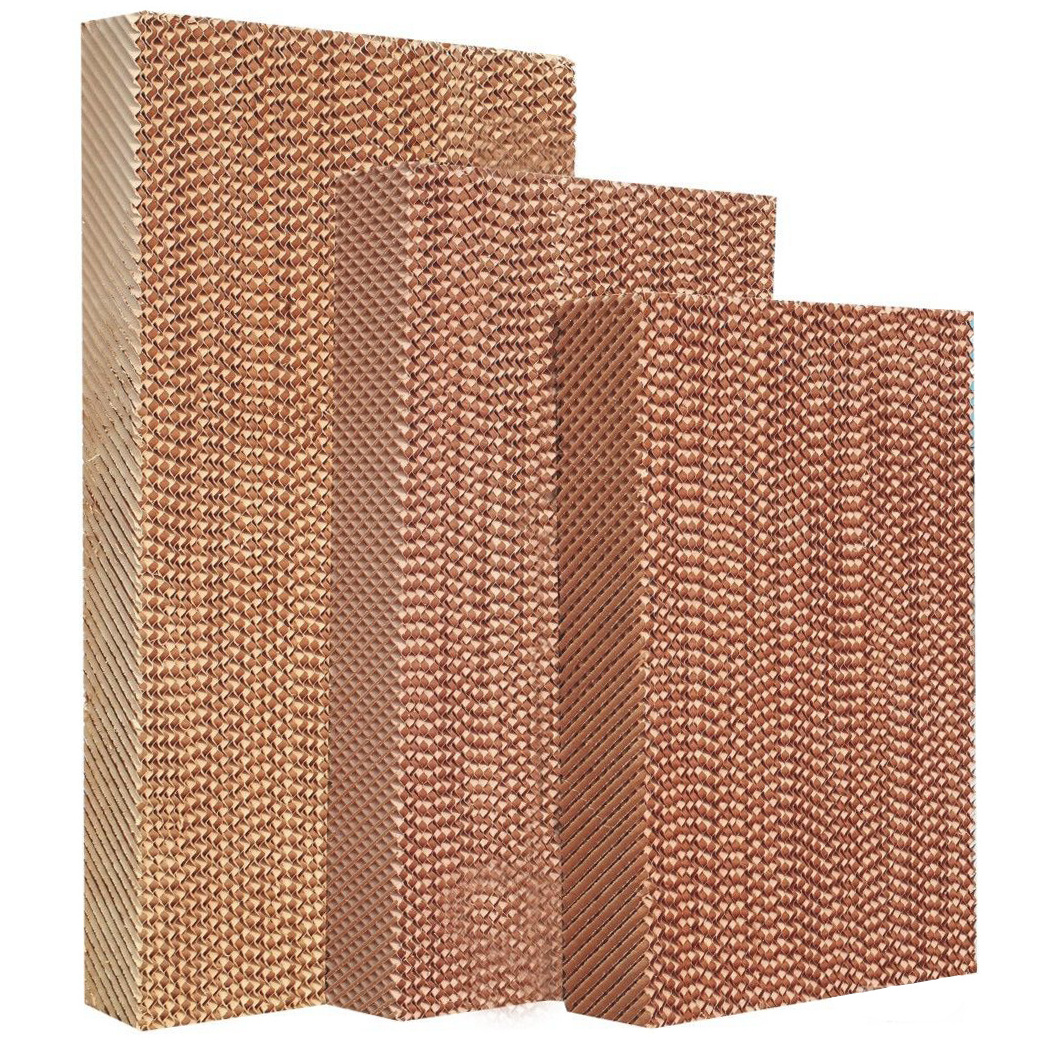

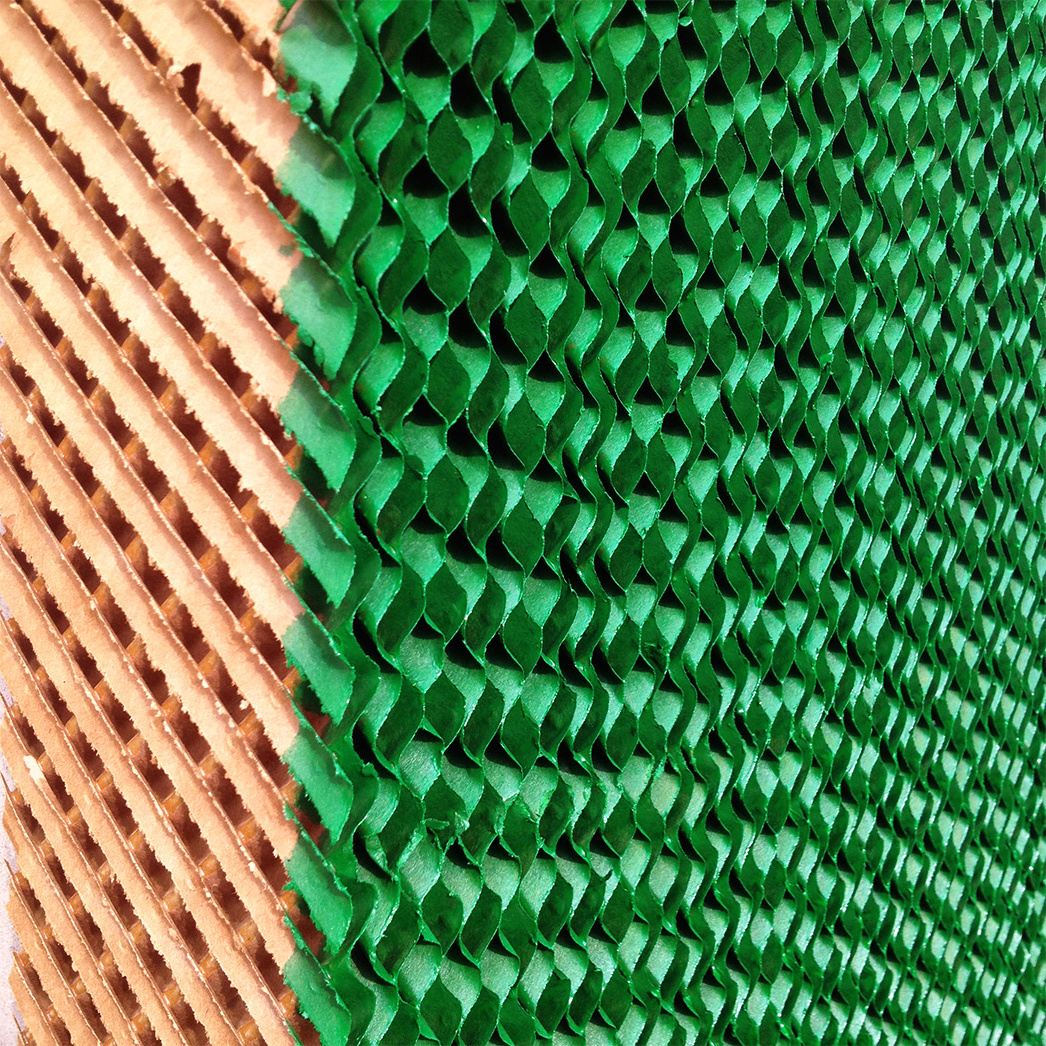

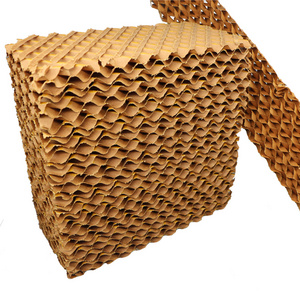

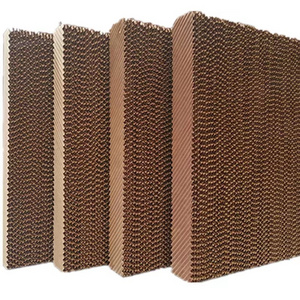

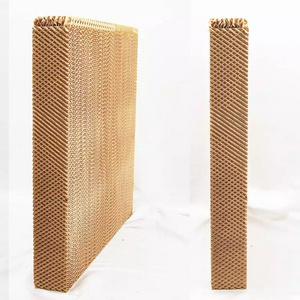

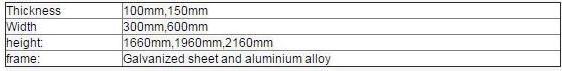

the cooling pad paper is bonding by corrugated fiber,the paper pulp is imported

the raw material of paper is added special chemical component by special craft technology

It isanti-corrosion, and long service life.

the corrugated fiber structure with some angle , it can provide enough surface area for air and water heat exchange,and purify the purify the air from outside , hai the natural filter performance.

1). Hygroscopicity: Though with the special craft processing crossing linking technology, corrugated paper

has high absorbality, high water resistant, anti-midew and long service life.

2). Dry solution: When water stop flowing on the cooling pad surface, the protective coating will dry quickly,

so it could prevent parasitic microbes survive on the surface, thus inhibiting the algae and other organic matter from breeding in the surface.

3). Non-porous surfaces: Prevent the alage and mineral substance from residing in the deep, and drying off the surface.

best combination

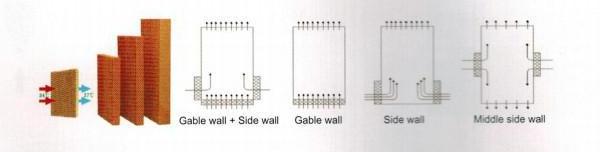

The longitudinal way of cooling-fan ventilation way is the most economical and effective and effective way to reduce temperature of chicken house in summer.

According to many years of practice, even in the hottest summer , with reasonable designed and installed ventilation system, it still can control the temperature of chicken house under 30 degree, then make the effect of hot temperature on the growth of poultry to minimum

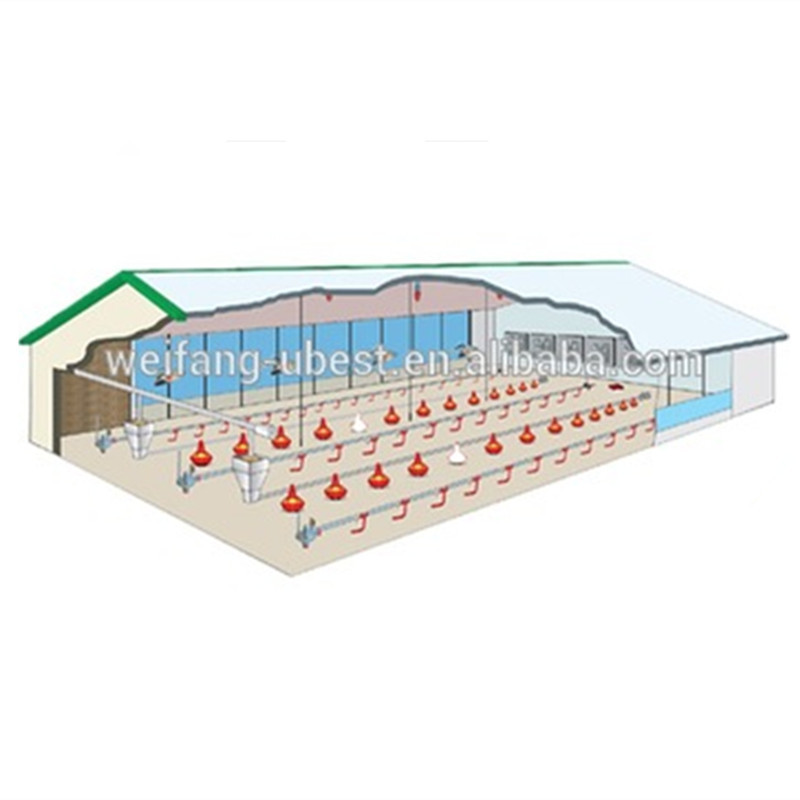

Main system equipment for chicken farm farm

| 1.Main feed line system: |

Silo /manpower hopper is the beginning of main feed line.There is a feed sensor at the end of main feed line which controls motor on and off to achieve automatic feed delivery. |

| 2.Automatic pan feeding line system: |

There is a feed sensor at the end of each feeding line which controls motor one and off to achieve automatic feed delivery to each feed pan. |

| 3.Automatic Nipple drinking line system: |

supply clean water to each nipple steady, chicken can drink water from 360 degree, freely |

| 4.Ventilation system: |

make chicken shed keep suitable temperature for different stage chicken |

| 5.cooling pad system: | The longitudinal way of cooling-fan ventilation way is the most economical and effective way to reduce temperature of chicken house in summer. |

| 6.Environment control system: | A variety of environment controllers are customized from Israel,it can reach a most advanced control leave in poultry house control. |

| 7.Fogging system: | It is effectively tools for cooling,damping,dedusting and disinfecting the house. |

| 8.Heating system: | In winter or chicks,it make chicken house has a suitable temperature. |

Main Feed line System

silo/manpower hopper is the beginning of main feed line. There is a feed sensor at the end of main feed line which controls motor on and off to achieve automatic feed delivery from silo or manpower hopper/feed bin to vice hopper in each feeding line.

silo with standard ladder and guard railing is safe and reliable.

solid connection and good sealing pr\erformance

manpower

Volume:

600kg 800kg 1200kg

driving motor

:

power

:

0.75kw/1.1kw/1.5kw voltage:0.75kw/1.1kw/1.5kw Frequency:50hz/60hz, 3phase/1phase

Feed sensor:

IFM brand from Germany.

.

Automatic Pan Feeding Line System

The feed in the silo is transported to the hopper of the feed line,And the transmission closure of the driving motor is controlled by the feed level sensor

.

Tube

Φ45mm diameter

material

:

hot-dip galvanized steel pipe with the zinc coating amount of more than 275/m2

Auger

:

Helical spring auger imported from

South Africa,

Feeding ability

:

450kg/h

Pan Feeder

4 pans/3 meters, 3 pans/3 meters.

Feed Sensor

:

IFM from

Germany

, time delay range 0 to 2 hours.

when feed sensor is installed inside the feed pan(connect to open),driving motor starts work to convey feed , when feed sensor dose not touch feed,and it shops conveying feed when feed sensor touchs feed (for main feed line and pan feeding line use)

feed pan

feedpan slide switch could adjust feed flow until it is filled.

pan bottom can be disassembled on the ground,working for day-old chicken.

Vpan place design can reduce feed storage on bottom, so birds can always eat fresh feed. the design can also prevent birds from staying too long on the plate.

the edge of pan plate tilt towords the center, which can avoid waste of food.

thesmooth edge can prevent the craw of birds from hurting and make sure safety and comfort feeding.

feed pan installation has fixed type or swing type.

.

Automatic Nipple Drinking system

This system can provide fresh and clean water for poultry which is crucial for the growth of poultry.

main part the system:filter, purssure regulater , nipple drinking line , lifeing and suspension system, electric shock system etc.

Ventilation System

This system controls climate conditions, fresh air, humidity and temperature in poultry shed. It is vital for growing chicken, including air inlets and ventilation fan.

Fan

horizontal fan

Remove harmful gases and ensure the indoor air is fresh.

longitudinal fan

cooperation cooling pad ,Cool down

ventilation fan

Remove harmful gases and ensure the indoor air is fresh.

cooling pad system

the cooling pad paper is bonding by corrugated fiber,the paper pulp is imported

the raw material of paper is added special chemical component by special craft technology

It isanti-corrosion, and long service life.

the corrugated fiber structure with some angle , it can provide enough surface area for air and water heat exchange,and purify the purify the air from outside , hai the natural filter performance.

1).

Hygroscopicity

: Though with the special craft processing crossing linking technology, corrugated paper

has high absorbality, high water resistant, anti-midew and long service life.

2).

Dry solution:

When water stop flowing on the cooling pad surface, the protective coating will dry quickly,

so it could prevent parasitic microbes survive on the surface, thus inhibiting the algae and other organic matter from

breeding in the surface.

3).

Non-porous surfaces:

Prevent the alage and mineral substance from residing in the deep, and drying off the

surface.

best combination

According to many years of practice, even in the hottest summer , with reasonable designed and installed ventilation system, it still can control the temperature of chicken house under 30 degree, then make the effect of hot temperature on the growth of poultry to minimum

Environment Control System

Environment control system saves labors and resources under the condition of assuring a optimum growth environment for poultry chickens.

A variety of environment controllers are customized are customized from Israel, it can reach a most advanced control level in poultry house control.

Environment controller is designed to control poultry breeding equipment automatically and intelligently according to local climate and equipment requirements.

Fogger system

This system effectively cools, humidifies, remove dusts and disinfects poultry house.

Fogging system outfit

Copper nozzle

Main engine water absorbing capacity:20-38/min

Water filter though 4 groups entered pumping system to ensure fogging system quality.

Install 3 fogging lines in standard chicken house , double-hole nozzle interval of 3 meters to ensure that no spray dead corners

In chicken house , branched passages are high pressure nylon tube , which resist from corrosion. the main passages is High pressure purple copper pipe, which enter into the sprating line by two passages.

To ensure same thoughout the spray pressure, spray enenly 25-30 micron aerosol particles.

plastic nozzle

Main engine water absorbing capacity:901/min

Water filter though 4 groups entered pumping system to ensure fogging system quality.

Install 3 fogging lines in standard chicken house,five-hole nozzles , nozzle interval of 4 maters to ensure that ni spray dead corners

In chicken house , passages are high quality PVC pipe, which resist from corrosion . 45-55micron aerosol particles.

Heating system

Function:Warm poultry shed to satisfy the temperature demand of baby chicks or whole chicken house.

Optional heaters:

1).Hot blast heater of coal or diesel: heat the whole chicken house,

2).Gas brooder: heat the day old chick.

3). Gas heater: heat whole chicken house, quantity needed are based on chicken shed area.

PACKAGING: Automatic chicken feeding machine for export sale is Standard Export Package in container

SHIPPING:15 Days

Our vision:To be standardized, competitive and internationalized.

Our mission:To provide world-class technology, world-class product quality and world-class customer

service

Our values:To insist on being people-oriented, upholding absolutely honest operation and

achieving continues advancements