- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Product name:

-

Plastic PP Bath Tub

-

Application:

-

plastic tray, panel, pallet

-

Process:

-

Vacuum forming, thermoforming

-

Design & size:

-

customized

-

Material:

-

Plastic ABS, PS or customized

-

Material thickness:

-

1-12mm

-

Color:

-

White, black or customized

-

Certification:

-

ISO9001:2008

-

MOQ:

-

150 pcs

-

Business type:

-

Factory, Manufacture

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Hongwei

-

Model Number:

-

Customized

-

Product name:

-

Plastic PP Bath Tub

-

Application:

-

plastic tray, panel, pallet

-

Process:

-

Vacuum forming, thermoforming

-

Design & size:

-

customized

-

Material:

-

Plastic ABS, PS or customized

-

Material thickness:

-

1-12mm

-

Color:

-

White, black or customized

-

Certification:

-

ISO9001:2008

-

MOQ:

-

150 pcs

-

Business type:

-

Factory, Manufacture

Related Products

|

|

|

|

Product description

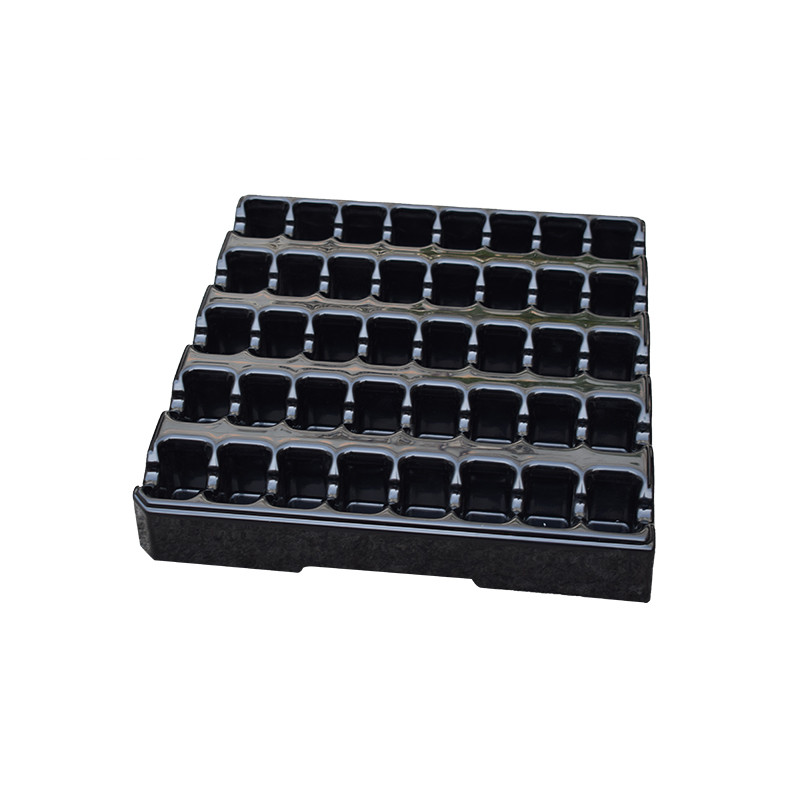

| Product name | Hot Sell Thick Thermoforming Tubs Hydroponic ABS Vacuum Forming Trays |

| Application | plastic parts, storage tray |

| Process | vacuum forming, thermofoming, thermoformed, vacuum formed |

| Design & size | Customized (2D or 3D drawing provided by client, within size 4000x2000x800mm) |

| Material | ABS, HIPS, PE, PET, PETG, PP, PVC, PC, PMMA etc |

| Logo | Sticker, spray, printing, embossed, etc |

| Color | White, black or customized |

| Surface finishing | Mat, gross, mirror, texture |

| Package | polybag + export carton, or wooden case, or customized |

| Lead time |

5-7 days for tooling 10-12 days for samples 15-20 days for mass production |

| Shipping method | Sea, air or express |

| Payment term | 50% deposit + 50% before shipment |

| Company qualification | ISO9001:2008 |

| Business type | Manufacture, factory |

Application

Certification

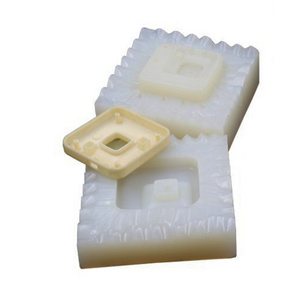

What is vacuum forming

Vacuum forming is a process in which a thermo plastic sheet is heated to the appropriate temperature, stretched around or into a mold or pattern, and conformed to the mold by applying vacuum pressure between the mold surface and the plastic sheet. Because heating of the material to be formed is required, vacuum forming is considered a thermoforming progress. The vacuum forming process can be used to make most packaging products and industrial fields like:

1. Auto & vehicle: auto bumper, truck & vehicle dashboard, ATV cart cover, plastic body, ATV side panel golf cart housing, car door, car accessories, auto parts, truck bumper, radiator grille, auto sapare parts

2. Hotel: plastic space capsule hotels hotel, hotel bunk bed, theme hotel

3. Machine & appliance: large machine cover, equipment shell, ABS large plastic products, medical device housing, large products, large parts

4. Boat & surfboard: fishing boat hull, surfboard shell, body, cover

5. Tray & pannel: plastic hydroponic tray, seedling growing tray, large thick plastic tray, inner 3D wall pannels, refrigerator TV covers, washing machine covers etc.

6. Display & advertising: large display box, signboard, gauge plastic parts, storage pannels, outdoor signboards, large size promotion bottle sign, exhibition display, advertising bottle, display bottle , cosmetic display, display stand, make up stand,

7. Others: Distortion printing: distortion maps, distortion silk screen printing, embossed signs holding plate, large plastic trays, luggage box, suitcase cover, electric car body, housing, shell

Vacuum forming and production progress

How to order

1) Clients send inquiry to us & provide 3D or 2D draqing or sufficient information (length x width x thickness, quantity, material, colors etc.

2) We offer quotation in time

3) Once price confired, we prepare PI or contract

4) After PI & contract confirmed, client transfer 50% deposit to us. We as factory, prepare for tooling & mold

5) We release tooling & mold after deposit received

6) We produce samples & send to client for confirmation

7) We arrange mass production after samples approved. If any modification or change asked by clients, we will modify mold & re-make samples and send to client for approval again till confrimation.

8) Packing & delivery preparation. On the other hand clients transfer balance 50% payment.

9) On-time delivery after balance payment received.

10) B/L & other related documents send to clients once available.

1,ABS vacuum forming ,Acrylic vacuum forming,ASA vacuum forming,PMMA vacuum forming,PVC vacuum forming,PS vacuum forming,

PET vacuum forming,PP vacuum forming PC vacuum forming,PE vacuum forming etc.

2,ABS thick sheets vacuum forming,thick panel vacuum forming manufacturers selection material:ABS Vacuum forming,PS(HIPS)vacuum formed,

PP vacuum forming,PE(HDPE) vacuum formed ,PC vacuum forming ,PETG vacuum forming ,PVC vacuum formed,ABS/PMMA vacuum formed etc.

3,ABS thick sheets vacuum forming,,Thick panel vacuum forming supplier mainly products:thick vacuum formming,thick panel vacuum formed,Specail thick

vacuum formed,thick sheets vacuum formed,large vacuum forming,large thick vacuum forming etc.

4,ABS thick sheets vacuum forming,thick panel vacuum forming manufacturers,Application range:vacuum forming machine cover,vacuum forming display shelf,