- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Wood plastic profile machine

-

Voltage:

-

380KV

-

Dimension(L*W*H):

-

20m*2m*3m

-

Power (kW):

-

150

-

Weight:

-

15000 KG

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

156:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Wood plastic profile machine

-

Voltage:

-

380KV

-

Dimension(L*W*H):

-

20m*2m*3m

-

Power (kW):

-

150

-

Weight:

-

15000 KG

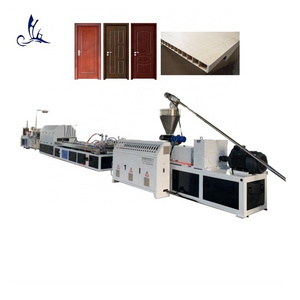

Wood plastic composite profile production machinery

I. OVERVIEW OF WOOD PLASTIC EXTRUSION LINE:

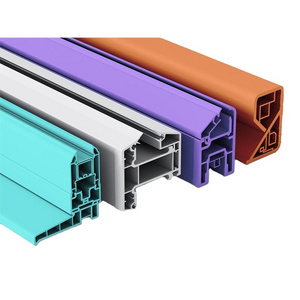

1.1 This extrusion line is suitable to produce PVC and Wood door profile for construction application.

1.2 power supply: 380 V/3 PHASE/50 HZ

1.3 Material: PVC powder

1.4 Extrusion capacity: 100 -500Kg/H

II.MACHINE SERIES OF WOOD PLASTIC EXTRUSION LINE:

| Extruder model | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Main motor power (kw) | 22 | 37 | 56 | 110 | ||

| Down-stream equipment model | YF240S | YF240A | YF300A | YF600 | YF900 | YF1200 |

| Product width (Max. mm) | 240 | 240 | 300 | 600 | 900 | 1200 |

| Vacuum pump (kw) | 2*5.5 | 4*5.5 | 4*5.5 | 4*5.5 | 1*7.5, 2*11 | 1*7.5, 2*11 |

| Water pump (kw) | 1.5 | 4 | 4 | 7.5 | 7.5 | 7.5 |

| Haul-off speed | 0-5 | 0-5 | 0-5 | 0-3 | 0-2.5 | 0-2.5 |

| Down-stream equipment power | 22 | 35 | 35 | 44 | 52 | 62 |

| Output (kg/h) | 70 | 120 | 120 | 180 | 400 | 400 |

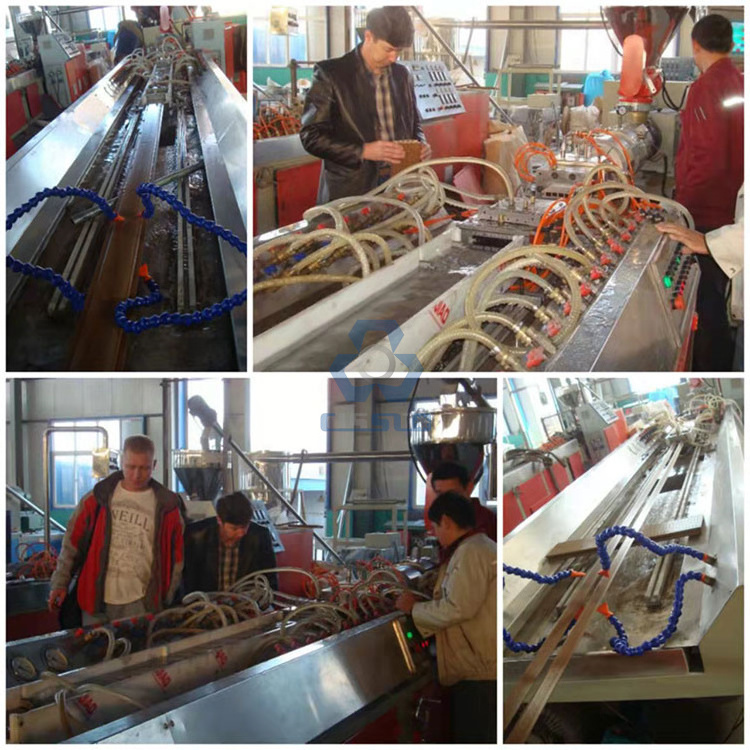

III. MACHINE LIST OF WOOD PLASTIC EXTRUSION LINE :

| No. | Name | Qty. | Remark |

| 1 | Extruder | 1set | Control by RKC meter |

| 2 | Die head and calibrating device | 1set | Make by customer’s requirement |

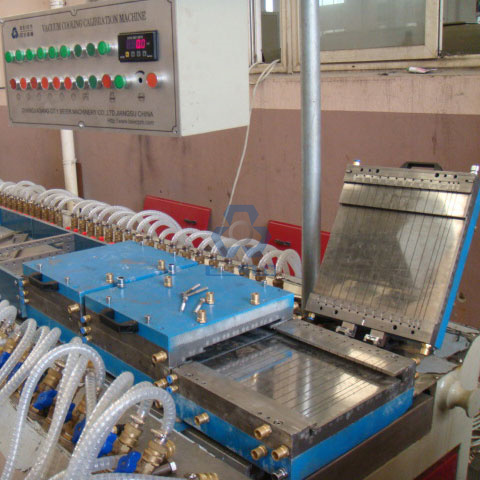

| 3 | Vacuum sizing table | 1set | |

| 4 | Haul-off unit | 1set | |

| 5 | Cutting unit | 1set | |

| 6 | S Tilter | 1set | |

| 7 | Loader device | 1set |

IV. PICTURES OF WOOD PLASTIC EXTRUSION LINE

• We design, engineer and manufacture and customized the extrusion line.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.