- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9300*900*1600mm

-

Power (kW):

-

31.3

-

Weight (KG):

-

3000 kg

-

Panel Feed Speed(m/min):

-

18m/min

-

Machine name:

-

woodworking automatic edge banding machine

-

Min Panel length:

-

≥160mm

-

Inclined Panel thickness:

-

15-25mm

-

Straight panel thickness:

-

10-60mm

-

Inclined degree:

-

45°

-

Inclined feeding speed:

-

15m/min

-

Straight feeding speed:

-

18m/min

-

Working pressure:

-

0.65mpa

-

Weight:

-

3000kg

-

Belt material:

-

PVC, ABS, WOOD etc.

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HUAHUA

-

Voltage:

-

380V/415V/220V

-

Dimension(L*W*H):

-

9300*900*1600mm

-

Power (kW):

-

31.3

-

Weight (KG):

-

3000 kg

-

Panel Feed Speed(m/min):

-

18m/min

-

Machine name:

-

woodworking automatic edge banding machine

-

Min Panel length:

-

≥160mm

-

Inclined Panel thickness:

-

15-25mm

-

Straight panel thickness:

-

10-60mm

-

Inclined degree:

-

45°

-

Inclined feeding speed:

-

15m/min

-

Straight feeding speed:

-

18m/min

-

Working pressure:

-

0.65mpa

-

Weight:

-

3000kg

-

Belt material:

-

PVC, ABS, WOOD etc.

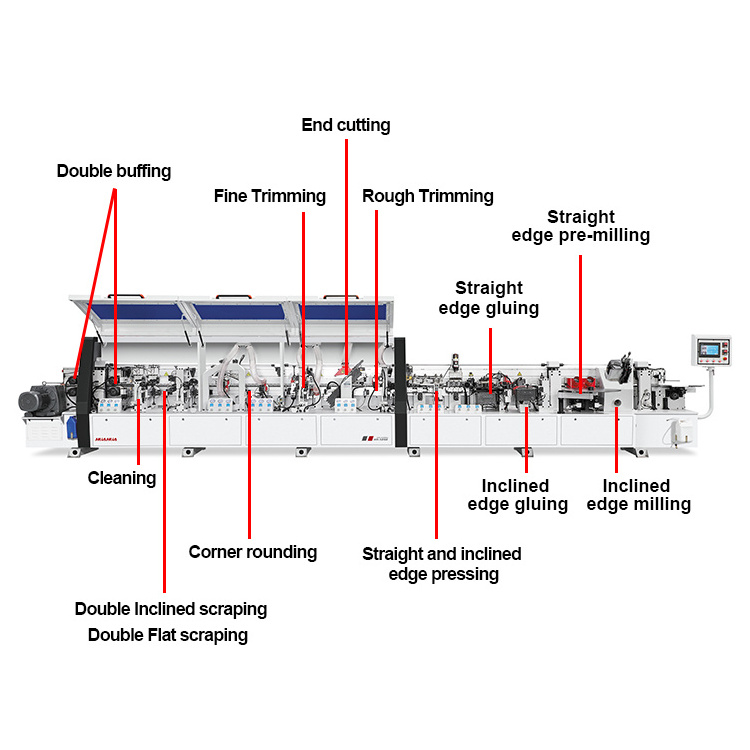

Products Description

Product Detail

bevel edge milling

The milling cutter mills the edge of the board into a beveled edge,

Adjustable tilt angle,

The hypotenuse is formed at a time.

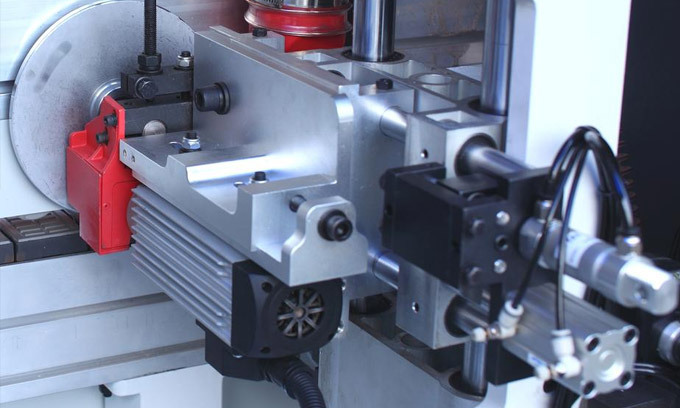

pre milling

Configure two 2.2KW motors,

It consists of two milling cutters before and after.

Maximum pre-milling height 40mm (optional 65mm),

Corrugation and expansion edge of milled plate surface,

Make the edge band and the plate fit more closely,

Integrity and aesthetics are better.

bevel edge gluing

Melt the glue after high temperature

Coated on the beveled side of the panel,

Perfectly fit the shape of the hypotenuse,

Even glue application guarantees the fit effect.

straight edge gluing

Melt the glue after high temperature

Apply to the straight side of the board,

Even glue application guarantees the fit effect.

Straight edge pressing

tape bonded to the panel

Pressurized by 4 straight pressing wheels,

Make the panel and tape fit more firmly

bevel edge pressing

Pressing through 4 oblique pressing wheels and 2 straight pressing wheels,

Make the panel and tape more firmly.

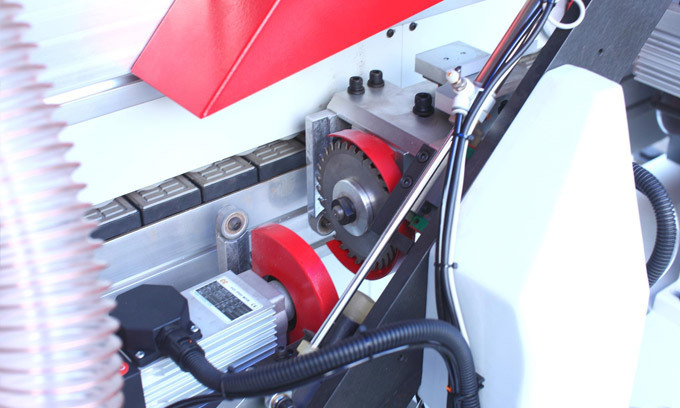

rough trimming

Automatic disc tracking

High-frequency high-speed motor structure,

Trimming the tape bonded to the oblique edges of the panel,

Repair the excess tape,

Make it milled into an edge with R arc.

End trimming unit with two high frequency motors

Through precise linear guide motion,

Adopting automatic tracking of the master and high-speed high-speed motor cutting structure,Edge band protruding from the front of the plateTrimming with the edge bands protruding from the back of the panel,

Make it flush with the front and back of the panel,Ensure that the cut surface is smooth and smooth.

Fine trimming

Adopt large and small disc automatic tracking

High-frequency high-speed motor structure,

Trimming the edge bands with straight edges bonded,

Repair and process the excess edge banding material on the upper and lower edges of the plate,

Make it milled into an edge with R arc.

Corner rounding

Adopt profile wheel rounding device for left and right movable profile,

Mill the four corners of the edge banding strip bonded to the panel into an R arc shape,

Make the 4 corners of the panel more smooth and beautiful.

R1 and R2 scrapping

Scrapping knife on both sides of the panel

Scrape the wavy knife marks on the tape due to rotation,

The modified R angle is the same size as the refined R angle,

Make the upper and lower parts of the panel more smooth and neat.

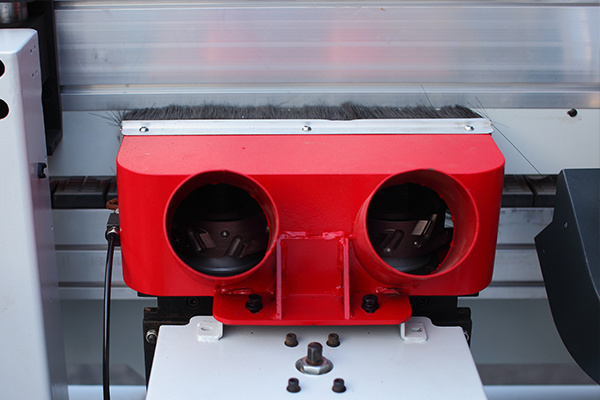

Double buffing

Through the two cloth wheels in rotation,

Clean the processed board,

Make the end face of edge banding more smooth and beautiful,

And keep the polishing wheel wear evenly.

|

Min. Panel length

|

≥160mm

|

Inclined feeding speed

|

15m/min

|

|

Min. Panel width

|

≥160mm

|

Straight feeding speed

|

18m/min

|

|

Inclined panel thickness

|

15-25mm

|

Total power

|

31.3kw

|

|

Straight panel thickness

|

10-60mm

|

Working Pressure

|

0.65mpa

|

|

Straight tape thickness

|

0.4-3mm

|

Size

|

9300*900*1600mm

|

|

Inclined tape thickness

|

0.4-1.5mm

|

Weight

|

3000kg

|

|

Inclined degree

|

45°

|

|

|

If you are interesed in our product,pls

click here

to contact us!

Packing&Delivery

Hot Searches