Q1:

Is injection moulding easy?

A1:

Plastic injection moulding is a complex manufacturing process commonly used to create plastic components. The ability of injection moulding to produce thousands of complex parts quickly makes it the perfect process for the mass production of plastic components.

Q2: What are the basics of molding?

A2: The basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold

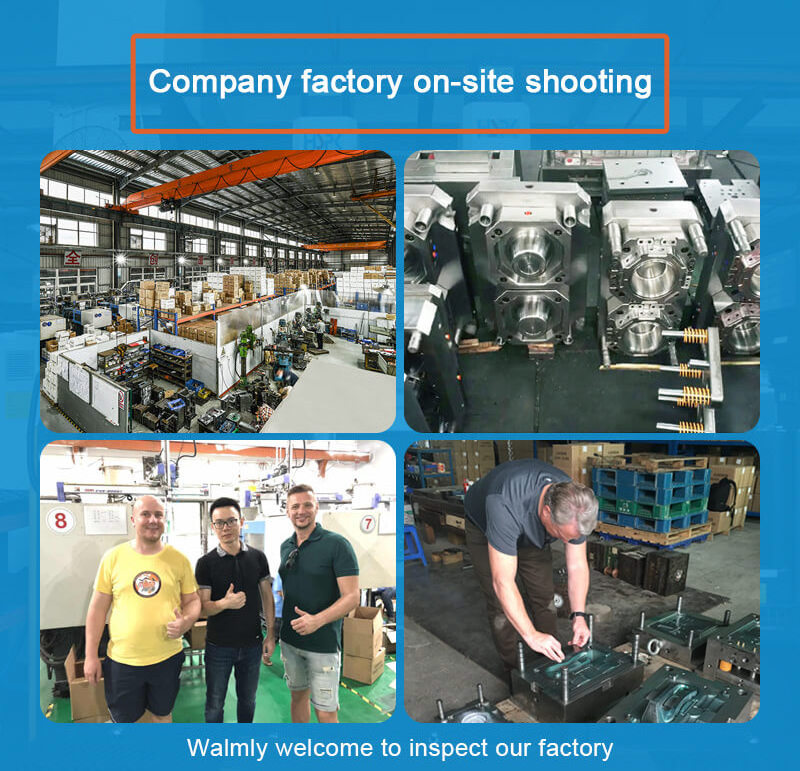

Q3: Are you an injection mold factory?

A3: Yes, We can provide one-stop service for mold making and plastic parts production and assembly

Q4:

How much does it cost to injection mold plastic?

A4.:

A small and simple single-cavity plastic injection mold usually costs between $1,000 and $5,000. Very large or complex molds may cost as much as $80,000 or more. On average, a typical mold that produces a relatively simple part small enough to hold in your hand costs around $12,000.

Q5.

Why does injection molding cost so much?

A5.

Injection molding includes high-precision molds whose design is time-consuming and labor-intensive. After having the 3D structure data of the product, it still needs to be fully analyzed sub-molded, and split 2D parts drawing. The choice of mold material has a great impact on the cost.

Q6.

What is tool in injection molding?

A6.

The mold is often referred to as tooling. Mold and tooling are relatively interchangeable terms for the metal mold at the heart of the injection molding process. Mold tooling may also be used to describe the process of machining the mold out of a block of metal.

Q7:

What is the most common material for injection molding?

A7:

These are the most common plastic materials for injection molding: acrylic (PMMA) acrylonitrile butadiene styrene (ABS) nylon(polyamide, PA)