- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3640x1550/1850mm

-

Power (kW):

-

3kw

-

Weight (KG):

-

2200 KG

-

Product Name:

-

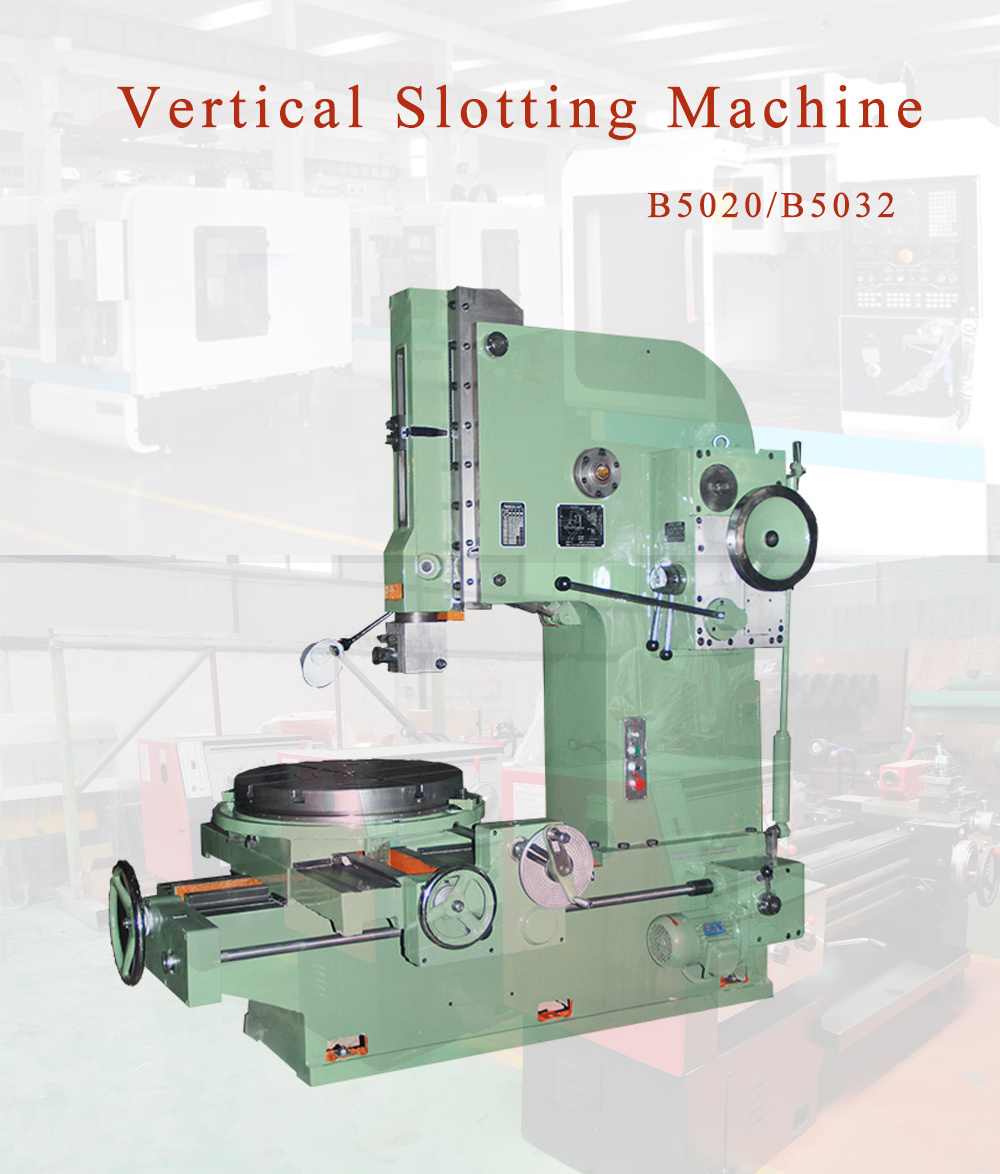

Vertical Slotting Machine

-

Model:

-

B5020 / B5032 / B5050 / B5063

-

Processing Types:

-

Mechanical Shaper Machine

-

Function:

-

Cutting Metal

-

Precision:

-

High Precision High Performance

-

Maximum Shaping Length:

-

660mm

-

Travel of tool head:

-

120/160mm

-

Number of ram strokes per minute:

-

80 Times/min

-

Max Slotting Length:

-

200/320/400/500

-

Table horizontal travel:

-

600 mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

Customer Requireme

-

Dimension(L*W*H):

-

3640x1550/1850mm

-

Power (kW):

-

3kw

-

Weight (KG):

-

2200 KG

-

Product Name:

-

Vertical Slotting Machine

-

Model:

-

B5020 / B5032 / B5050 / B5063

-

Processing Types:

-

Mechanical Shaper Machine

-

Function:

-

Cutting Metal

-

Precision:

-

High Precision High Performance

-

Maximum Shaping Length:

-

660mm

-

Travel of tool head:

-

120/160mm

-

Number of ram strokes per minute:

-

80 Times/min

-

Max Slotting Length:

-

200/320/400/500

-

Table horizontal travel:

-

600 mm

Product Overview

Slotting machine

Metal cutting machine tools are used to process groove features. During processing, the workpiece on the worktable performs longitudinal, lateral or rotational movement, and the inserting tool reciprocates up and down to cut the workpiece. A linear motion machine tool that uses the vertical reciprocating motion of the slotting tool to slot the keyway and the hole. The slotting machine, like the planer, also uses a single-edged tool (slotting tool) to cut the workpiece, but the planer is a horizontal layout, and the slotting machine is a vertical layout. Slotting machines have low productivity and accuracy. They are mostly used to process internal keyways or spline holes in single or small batch production. They can also process flat, square or polygonal holes, etc.

Product Specification

|

Specification

|

Unit

|

B5020

|

B5032

|

B5050

|

B5063

|

|

Max. Slotting length

|

mm

|

220

|

320

|

500

|

630

|

|

Worktable size

|

mm

|

500*500

|

630*560

|

1000*660

|

1120*700

|

|

Ram vertical adjustment distance

|

mm

|

230

|

315

|

430

|

500

|

|

Table Diameter

|

mm

|

500

|

630

|

1000

|

1120

|

|

Vertical and horizontal table power feed range

|

mm

|

0.08-1.21

|

0.08-1.21

|

0.1-1.2

|

0.1-1.2

|

|

Table rotary feed range

|

mm

|

0.052-0.783

|

0.052-0.783

|

0.052-0.783

|

0.052-0.783

|

|

Motor power

|

kw

|

3

|

4

|

7.5

|

10

|

|

Machine weight

|

kg

|

2200

|

3000

|

10000

|

10500

|

|

Outline dimension

|

mm

|

1916*1305*1995

|

2261*1495*2245

|

3480x2085x3307

|

3580x2390x3660

|

Type 1

Type 2

Type 3

Type 4

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary),therefore work object go through once clamping, Several surfaces in the machine tool machining

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer,

2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table.

3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously.

4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer,

5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

Details Images

Hot Searches