- Product Details

- {{item.text}}

Quick Details

-

Transformer:

-

400-6000kva

-

Melting time:

-

DEPEND ON

-

Melting metal:

-

All metal

-

Type:

-

Melting/CASTING

-

Color:

-

RED/BULE/OTHERS

-

Output:

-

DEPEND ON

Quick Details

-

Place of Origin:

-

CHINA

-

Product name:

-

Billet making continuous casting machine

-

Usage:

-

continuous casting machine.

-

Transformer:

-

400-6000kva

-

Melting time:

-

DEPEND ON

-

Melting metal:

-

All metal

-

Type:

-

Melting/CASTING

-

Color:

-

RED/BULE/OTHERS

-

Output:

-

DEPEND ON

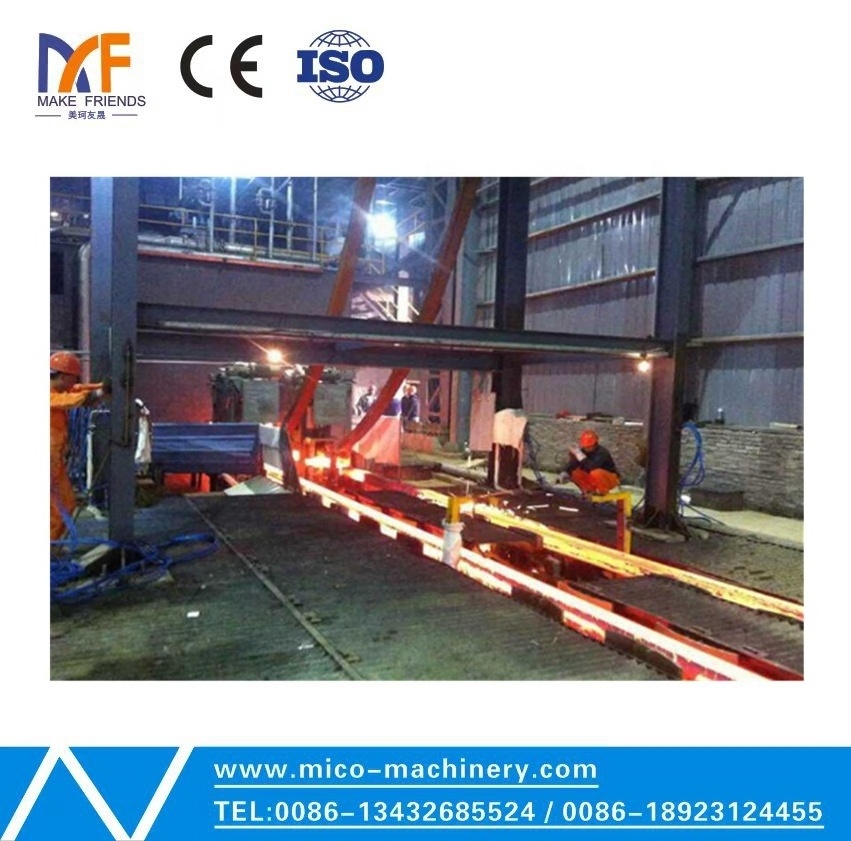

Billet making continuous casting machine

Production Description

Main Features

1) Based on customers project requirement and factory condition, provide the suitable capacity type.

2) Adopting advanced world famous brand components in main parts ,electric parts and operation parts.

3) Experienced overseas project successfully.

4) Running in a high automatization and intellectualization, high productivity and less maintenance.

5) Provide the integrated design from melting furnace to CCM and hot rolling mill .

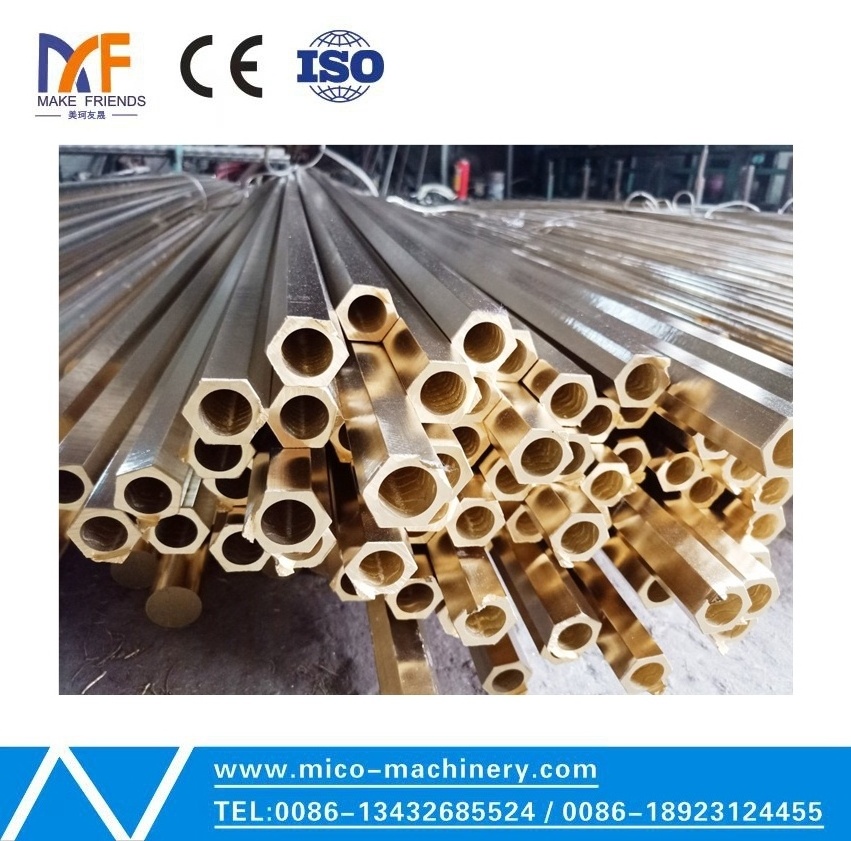

Major Volumes and Technical Parameters

|

Item No. |

Item |

Unit |

Specification |

|

1 |

CCM strands |

|

1-6 |

|

2 |

CCM type |

|

Rigid arc R6x1~6strand |

|

3 |

CCM arc radium |

m |

R6 |

|

4 |

Space of strands |

mm |

900-1200 if install the second line |

|

5 |

Crystallizer copper length |

mm |

812~900 |

|

6 |

Tundish capacity |

t |

based on design |

|

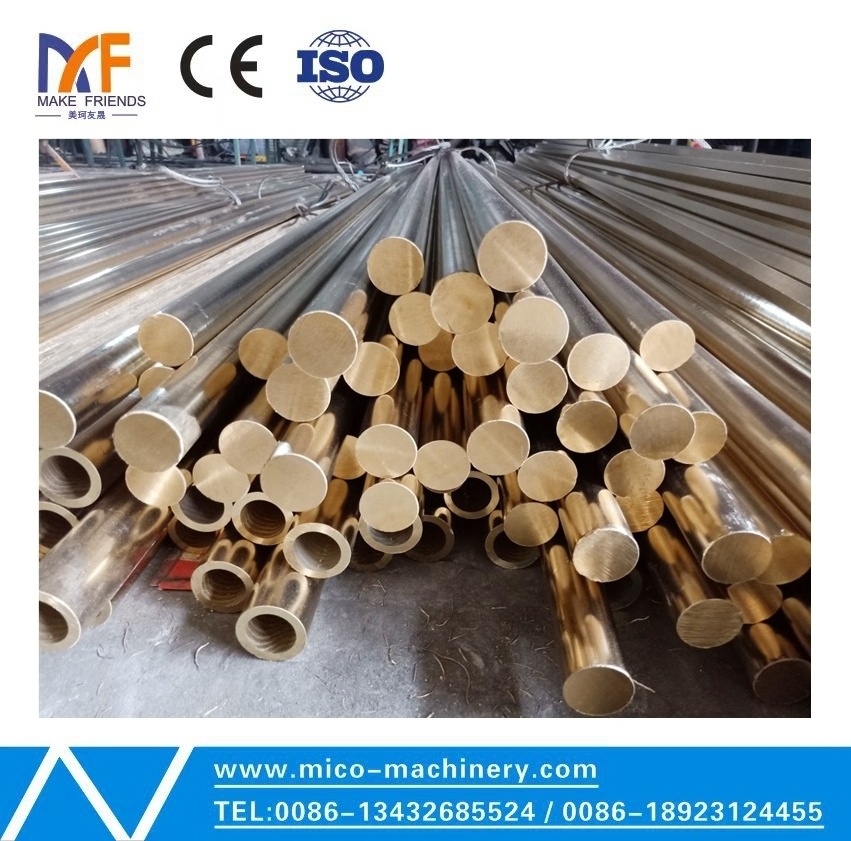

7 |

Billets section size |

mm |

120mm*120mm or reqiured |

|

8 |

Billets length rated |

m |

6.0 or reqiured |

|

9 |

D-S drawing velocity |

m/min |

0~5.0 |

|

10 |

D-S working drawing velocity |

m/min |

2~3.5 for 120mm2 sectionbillets |

|

11 |

Ladle molten steel |

t |

15~30/strand |

|

12 |

Qualified billets rate |

% |

99 |

|

13 |

CCM effective working time rate |

% |

~95 |

|

14 |

CCM productivity |

t/a |

50000~100000/strand |

Packing & Delivery

Our Company

About Us- After-sale Service

We provide not only excellent equipments, but also perfect after-sale service. Please submit the operation examination report of equipment regularly; we will put forward suggestions after analyzing the data. Safety use, stable operation and cost saving are common purposes that we work for together.

1.Answer customer technical enquiries, providing our customers with good circumspect service.

2.Provide customer floor plan and hydropower open cable after sign a contract within a week.

3. After design equipment programme, please user participation scheme review.

4. A period of product manufacturing, the user can at any time according to need to supervise the production schedule and quality inspection.

5. Provide to the customer complete,accurate,detailed technical information.

6.To the users? equipment installation technical guidance and equipment debugging

7.Provide the customer technology, maintenance, operation personnel theory and operation of training.

8.The warranty time a one year after buy equipment,lifetime service.

9. For all the use of equipment and follow up service and establish perfect after-sale service quality file.

10. All the preferential price to provide various spare parts, wearing parts.

11. Equipment malfunction, provide 24 hours service, help on time expel the

breakdown