- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

granule

-

Product name:

-

Butadiene Rubber

-

Material:

-

100%

-

DELIVERY TIME:

-

7-15days

-

MOQ:

-

10 Tons

-

Port:

-

Shanghai

-

Key word:

-

BR rubber

-

Purity:

-

99.99%

-

pack:

-

25kg

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

westvirginia

-

color:

-

white block

-

Shape:

-

granule

-

Product name:

-

Butadiene Rubber

-

Material:

-

100%

-

DELIVERY TIME:

-

7-15days

-

MOQ:

-

10 Tons

-

Port:

-

Shanghai

-

Key word:

-

BR rubber

-

Purity:

-

99.99%

-

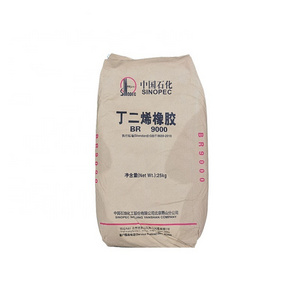

pack:

-

25kg

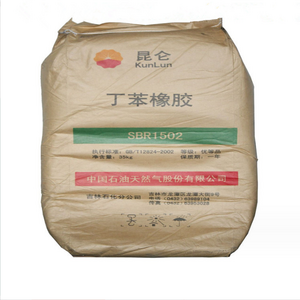

(BR) Butadiene Rubber - WVC-9000 WVC-9010 - Block

Product Introduction :

Butadiene Rubber (BR), also known as Polybutadiene, is a synthetic rubber primarily composed of 1,3-butadiene monomers.

It is one of the most common types of synthetic rubber and is known for its high resistance to wear and excellent elasticity. BR is particularly valued in tire manufacturing due to its ability to improve the abrasion resistance and low-temperature performance of tires.

Chemical Structure :

The polymer chain of BR is made up of repeating units of 1,3-butadiene, with the chemical formula (-CH2-CH=CH-CH2-)n, where 'n' denotes the number of repeating units.

The structure can vary in terms of the configuration of the butadiene units (cis, trans, or vinyl), which significantly affects the rubber's properties. The most common form used in tire manufacturing is the high-cis BR.

Product Features:

l Elasticity and Flexibility: Exhibits high elasticity and flexibility, especially at low temperatures.

l Abrasion Resistance: Offers excellent resistance to wear and tear, making it ideal for products that require durability.

l Low-Temperature Performance: Maintains good physical properties even at low temperatures.

l Resilience: High resilience, which is crucial for applications like tires where energy efficiency is important.

l Processing: Can be processed using conventional rubber processing techniques.

|

|

WVC 9000 |

WVC 9010 |

|

Appearance is Appearance |

White Block |

White Block |

|

Mooney viscosity ML(1+4) 100°C |

45 |

45 |

|

volatile matter%≤ |

0.5 |

0.75 |

|

The tensile strength is measured at MPa 35min |

≥13.2 |

≥14.5 |

|

Elongation% 35min |

≥330 |

≥365 |

Applications:

l Tire Manufacturing: Widely used in the production of tires for automobiles, trucks, and aircraft, particularly in the tread portion for its wear resistance and low-temperature performance.

l Golf Balls and Sporting Goods: Utilized in the cores of golf balls and other sporting goods for its elasticity and resilience.

l Footwear: Used in the production of shoe soles for its durability and comfort.

l Conveyor Belts and Hoses: Employed in industrial applications like conveyor belts and hoses for its strength and abrasion resistance.

l Automotive Parts: Utilized in various automotive parts, including under-the-hood components, due to its temperature and abrasion resistance.