- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

400

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Philippines, Saudi Arabia, Malaysia, Morocco, Algeria

-

Raw Material:

-

PIPE

-

Extra Services:

-

Slotting & Notching

-

name:

-

cnc auto bending machine

-

Material height:

-

25mm-150mm

-

Material thickness:

-

0.4--1.0mm

-

Width of flange:

-

6mm-14mm

-

Max bending angle:

-

120

-

Min radius for circle:

-

R10

-

Letter range:

-

80mm and more

-

Voltage:

-

AC 220V

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ledio

-

Year:

-

2020

-

Weight (KG):

-

400

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Philippines, Saudi Arabia, Malaysia, Morocco, Algeria

-

Raw Material:

-

PIPE

-

Extra Services:

-

Slotting & Notching

-

name:

-

cnc auto bending machine

-

Material height:

-

25mm-150mm

-

Material thickness:

-

0.4--1.0mm

-

Width of flange:

-

6mm-14mm

-

Max bending angle:

-

120

-

Min radius for circle:

-

R10

-

Letter range:

-

80mm and more

-

Voltage:

-

AC 220V

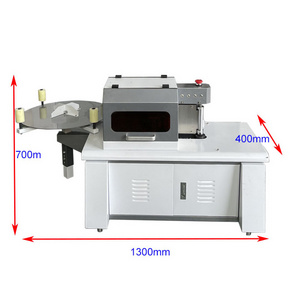

guangzhou automatic flange channel letter bending machine/auto bender

LEDIO BENDER is with full functions for the channelletters fabrication: auto notching, auto flanging, auto bending and auto cutting. It can be used to produce the returns of the channelletters with Aluminum, Stainless steel and Galvanized steel. Besides all the functions of the EZ BENDER C, it also has the flanging and notching functions especially for the Aluminum.

ATC

All the actions are controlled by the computer automatically.

Features

1.The interface of the software is very friendly.It can accept all kinds of DXF files such as created by ILLUSTRATOR, CASMATE, TYPE3,ARTCAM, FLEXISIGN, ENROUTER, CORELDAW etc.

2.The times and the depth of the slotting can be adjusted in the software. It’s very easy to use.

3.Hydraulic station controls the notching and flanging function. It’s very powerful and fast and the cutting surface is very smooth without any burrs.

4.Servo system controls the bending and slotting functions with high speed and high precision.

SPECIFICATION

| Material height | 25mm-150mm | |||||

| Material thickness | 0.4--1.0mm | |||||

| Width of flange | 6mm-14mm | |||||

| Max bending angle | 120 | |||||

| Min radius for circle | R10 | |||||

| Air | 90psi(6bar)at 1cfm | |||||

| Power | 220V/380V,3Phase 50 or 60 HZ,15Amp | |||||

| Package size | 1880(L)x940(W)x1760(H) mm | |||||

| Physical layout | 3350(L)x1000(W)x1500(H) mm | |||||

| Net weight | 550kg | |||||

| Gross weight | 650kg | |||||

Sample