- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

Nadun

-

Power (kW):

-

22 kW

-

Weight (KG):

-

15000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

3440mm*2300mm*2500mm

-

Year:

-

2023

-

Color:

-

Customer Requirement

-

Stroke Times:

-

8 times/min

-

Material Strength:

-

≤450 kn/cm

-

Application:

-

Industrial Metal Cutting

-

Product name:

-

Hydraulic Cnc Shearing Machine

-

Name:

-

Mechanical Shearing Machine

-

Type:

-

QC12Y/QC12K-20*2500

-

Keyword:

-

Hydrualic Shearing Machine

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

20 mm

-

Shearing Angle:

-

3°

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

250 mm

-

Brand Name:

-

Nadun

-

Power (kW):

-

22 kW

-

Weight (KG):

-

15000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V-440V

-

Dimension(L*W*H):

-

3440mm*2300mm*2500mm

-

Year:

-

2023

-

Color:

-

Customer Requirement

-

Stroke Times:

-

8 times/min

-

Material Strength:

-

≤450 kn/cm

-

Application:

-

Industrial Metal Cutting

-

Product name:

-

Hydraulic Cnc Shearing Machine

-

Name:

-

Mechanical Shearing Machine

-

Type:

-

QC12Y/QC12K-20*2500

-

Keyword:

-

Hydrualic Shearing Machine

Product Description

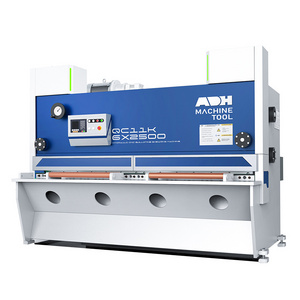

The Nadun`s shearing machine

The Nadun 20mmx2500mm CNC pendulum shearing machine model is QC12K-20mmX2500, the whole frame welding strong and durable; Use accumulator cylinder return, smooth and fast; Adjust the edge clearance of the upper and lower blades through the handle; With DAC360 CNC system, DAC360 CNC system and built-in encoder to form a closed-loop control system, fast speed, high precision, good stability.

Details Images

Frame Rigidity Enhancement Treatment

The frame components are processed by high-precision large gantry machining center, and the automatic welding improves the welding uniformity. In addition, vibration aging technology is used to eliminate the residual stress after welding to ensure the durability and ability of the frame.

MACHINE FEATURES

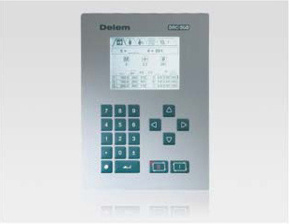

DELEM DAC360

High definition LCD display, 128×64 pixels

Control of rear stopper

Control of edge clearance

Shear stroke control

The actual position of the rear stopper is displayed synchronously with the programming value

Shear counting

100 program steps

Panel mounting

Servo control/frequency control/two speed AC

Motor control

BACKGAUGE

Accuracy ball screw,to ensure the stop position precision;Synchronous transmission construction of unique design,stable and reliable;Optional servomotor.

HYDRAULIC SYSTEM

Hydraulic drive,smooth,reliable,effectively reducing the problems caused by hydraulic oil leakage.

SPECIFICATION

Related Products

Packing & Delivery

Internal plastic moisture-proof anti-rust packaging,

External wooden packaging,

Exclusive container transport.

Hot Searches