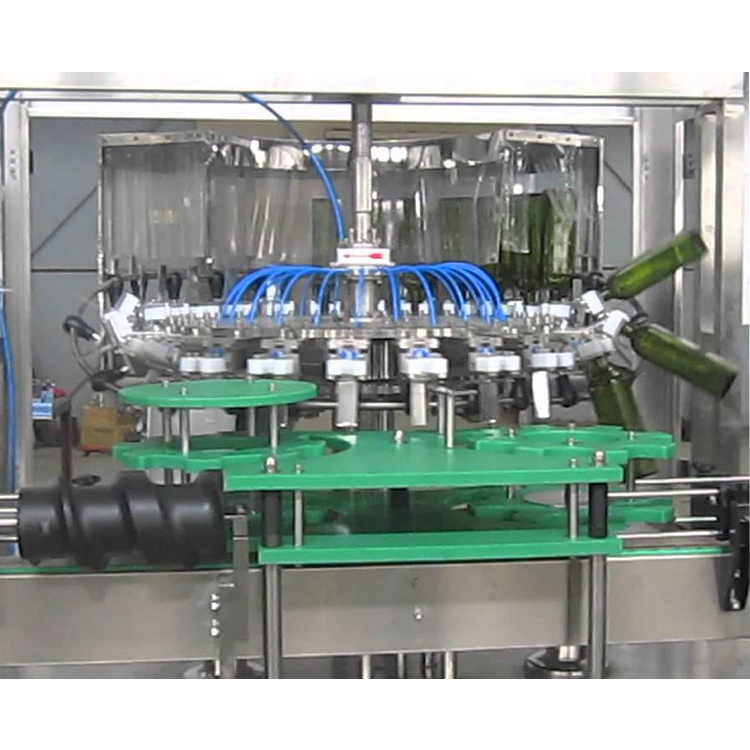

2.) Continuous tracking bottle - punching, bottle - punching force, long time.The washing effect is good. Each clamping hand part is equipped with a control sprinkler device, no bottle does not flush, saving water economy.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110v/220v/380v

-

Power:

-

1.2kw

-

Weight:

-

360 KG

-

Dimension(L*W*H):

-

L1100*W1100*H1700mm

-

Processing Types:

-

Bottle, Rotary rinsing

-

Product Name:

-

Bottle washing machine

-

Capacity:

-

1000-3000bottles/hour

-

Function:

-

Bottle rinsing

-

Bottle size:

-

10ml-1500ml

-

Bottle type:

-

PET Plastic Bottle, Glass Bottle

-

Cleaning medium:

-

Water or clean air

-

Material:

-

SUS304

-

Control:

-

Button

-

Advantage:

-

20 Years Experiences

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Drinks

-

Voltage:

-

110v/220v/380v

-

Power:

-

1.2kw

-

Weight:

-

360 KG

-

Dimension(L*W*H):

-

L1100*W1100*H1700mm

-

Processing Types:

-

Bottle, Rotary rinsing

-

Product Name:

-

Bottle washing machine

-

Capacity:

-

1000-3000bottles/hour

-

Function:

-

Bottle rinsing

-

Bottle size:

-

10ml-1500ml

-

Bottle type:

-

PET Plastic Bottle, Glass Bottle

-

Cleaning medium:

-

Water or clean air

-

Material:

-

SUS304

-

Control:

-

Button

-

Advantage:

-

20 Years Experiences

Glass Bottle Cleaning / Washing / Rinsing Machine

|

Model

|

XPJ-12

|

XPJ-18

|

XPJ-24

|

XPJ-32

|

|

Power

|

1.2kw

|

1.5kw

|

1.8kw

|

2.5kw

|

|

Size

|

L1100*W1100*H1700mm

|

L1600*W1600*H1850mm

|

L1800*W1800*H2000mm

|

L2000*W2000*H2200mm

|

|

Weight

|

360kg

|

600kg

|

950kg

|

1500kg

|

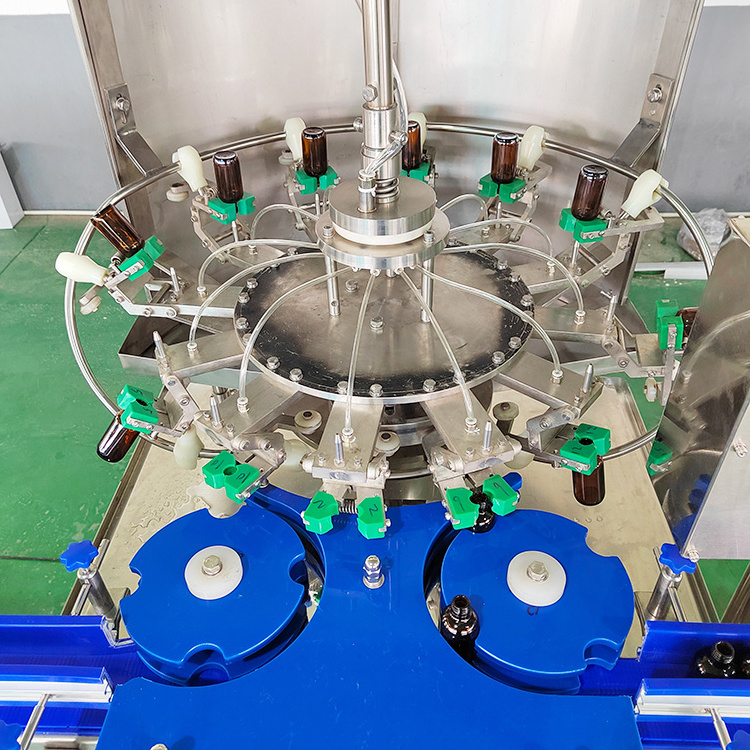

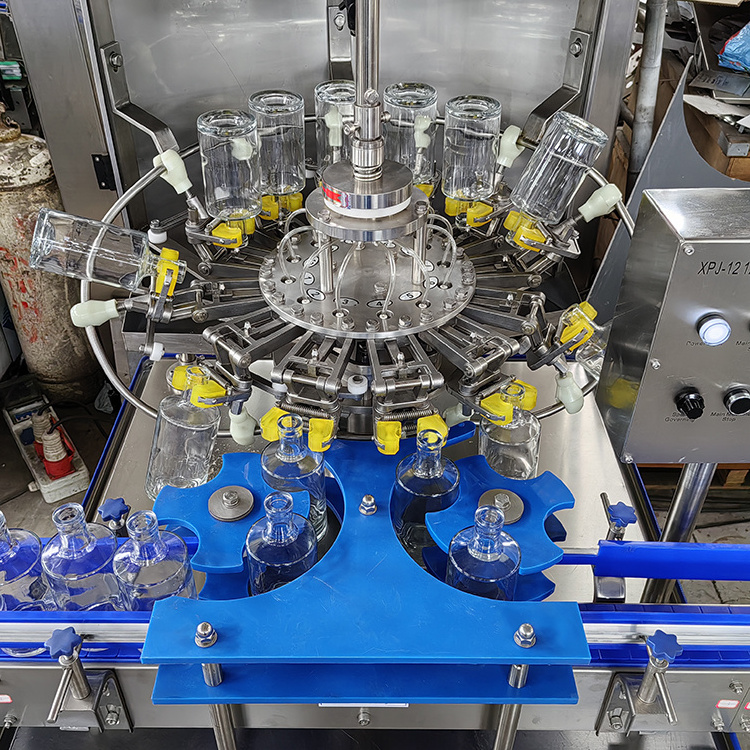

Detail picture display

1.) 18 Rinsing nozzles, each hour can be rinsed 1000-4000 bottles of production, high efficiency, saving.

3.) The mechanical hand stamping parts and casting materials are all made of national standard 304 material, which ensures the corrosion resistance of the material.The manipulator has the characteristics of accurate positioning and easy turnover of the bottle.

4.)The key is clear and clear, and the operation is easy to understand.

(1) The power switch. (2) The water pump switch. (3) The water pump switch.

(4) The abrupt stop switch. (5) Automatic, manual switch. (6) Adjustable speed switch.

5.)The power control equipment of ac motor is controlled by changing the working power frequency of the motor.

Transport Port : Shanghai Port.

Transportation: By van ,by train, by plane.

Packaging Details :Machine will be packed by PVC film+ standard wooden case or carton.

Wooden case suitable for long distance ocean shipping.

Q1: Are you factory or trading company?

A: We are direct factory and manufacture.

Q2: What kind of product you supply?

A:Beverage filling machine for water,juice,carbonated beverage and etc;packing system;water treatment system;PET bottle blowing machine,etc.

Q3: Where is your factory located? How can I visit your factory?

A: We are located in Zhangjiagang city, it is near to Shanghai and Wuxi. You can fly to Shanghai airport or Wuxi airport,we can pick you up from the airport or your hotel.

Q4: About installation?

A: We will send one-two engineers to your factory, to install the machines and train your staff how to operate the machines,it usually take 10 days to 25 days.

Q .5 Which country do you export your machines already?

A; J&D have exported bottling and associated equipment to the USA,UK,Ireland,Canada,Australia,Mexico,Russia,Africa.