CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts, more commonly used to create cylindrical parts, such as custom hollow tubing and shafts.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

xmanchor

-

Service:

-

Customized OEM CNC Machining

-

Size:

-

Customized Size

-

Surface treatment:

-

sandblasting/anodizing/polish/brushed / etc.

-

Process:

-

Cnc Machining+deburrs

-

QC Control:

-

100% inspection

-

Logo:

-

Accept Custom Logo

-

Keyword:

-

CNC Brass Accessory

-

Tolerance:

-

+/-0.01mm

-

MOQ:

-

1 Piece

Quick Details

-

Material:

-

Carbide, HIGH SPEED STEEL, Tungsten Cobalt Alloy

-

Type:

-

End Mill, Convex Mill, Face Mill

-

Finish:

-

Bright(Uncoated), Longer Life TiCN, Steam Oxide Nitride, Super Life TiAlN

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

xmanchor

-

Service:

-

Customized OEM CNC Machining

-

Size:

-

Customized Size

-

Surface treatment:

-

sandblasting/anodizing/polish/brushed / etc.

-

Process:

-

Cnc Machining+deburrs

-

QC Control:

-

100% inspection

-

Logo:

-

Accept Custom Logo

-

Keyword:

-

CNC Brass Accessory

-

Tolerance:

-

+/-0.01mm

-

MOQ:

-

1 Piece

- CNC SERVICE -

CNC Turning

CNC Milling

Milling is the cutting of a material such as wood,metal,or plastic using a rotating tool.The controls in CNC milling dictate everything from the sequence of tools used and the toolpath of each cutter,to the spindle RPM and feed rate.

|

Product Details:

|

|

|

|

|

||||

|

Name

|

Customized cnc machining parts, cnc aluminum parts, cnc turning milling parts

|

|

|

|

||||

|

Machining Equipment

|

DMG 5 axis cnc machining center /DMG composite cnc machine/Machining Center/ CNC Lathes/Grinding Machines/Milling Machines/Lathes/Wire-cuts/Laser Cuts/ CNC Shearing Macines/CNC Bending Machines/etc.

|

|

|

|

||||

|

Materials

|

1. Aluminum Alloy: 5052/ 6061/ 6063/ 2017/ 7075/ ADC12/ 518 etc.

|

|

|

|

||||

|

|

2. Brass Alloy: 3602 /2604 /H59 /H62 etc.

|

|

|

|

||||

|

|

3. Steel Alloy: Carbon Steel /Die Steel /Spring Steel etc.

|

|

|

|

||||

|

|

4. Other Special Materials: Lucite /Nylon /Bakelite /POM /ABS /PP /PC /PE /PEEK /Titanium etc.

|

|

|

|

||||

|

Surface Treatment

|

Blacking, polishing, sandblasting, anodize, chrome plating, zinc plating, pickling & passivation, vibration, nickel plating, tinting

|

|

|

|

||||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

|

|

||||

|

File Formats

|

Solid Works, Pro/Engineer, AutoCAD (DXF,DWG), PDF, TIF, IGS, STP etc.

|

|

|

|

||||

|

Quality Assurance

|

ISO9001:2008 Certified

|

|

|

|

||||

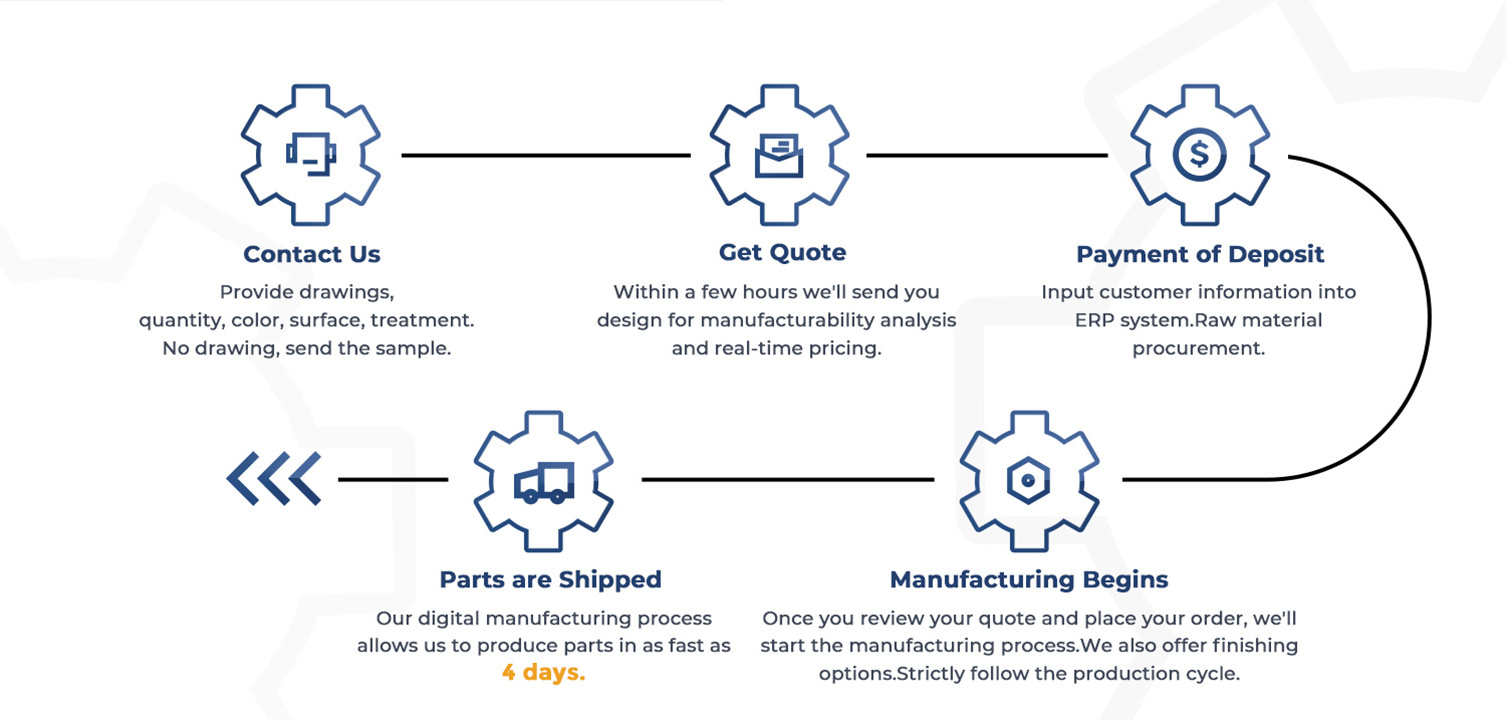

- HOW TO WORK WITH US -

- SURFACE FINISHING SERVICES -

Beyond corrosion protection, anodizing enhances the overall appearance of metal parts.Our anodizing processes are RoHS compliant.

Plating is commonly used to prevent corrosion, increase durability, alter surface friction, and improve appearance.

Brushing is used to deburr and remove surface defects from sheet metal parts.

Chromate plating is a conversion coating, which adds a protective layer over aluminum, titanium, and other metals.

Sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface,roughen a smooth surface,shape a surface or remove surface contaminants.

It uses polishing tools and abrasive grains or other polishing media to modify the surface of metal parts.

- About Us -

- FAQ -

Hot Searches