- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KaiYe

-

Model Number:

-

KY-FRQ-2500

-

Weight (KG):

-

15000

-

Power (kW):

-

5.5

-

HS Code:

-

8515219900

-

welded wire materials:

-

Low carbon steel wire,Galvanized wire, black wire.

-

Line Wire Spacing:

-

50-300 mm

-

Cross Wire Spacing:

-

50-300 mm

-

Fence mesh length:

-

75-2500 mm

-

Fence mesh width:

-

Max. 2500 mm

-

Welding Speed:

-

40-60 Times/min

-

Transformer:

-

150kva*6

-

Voltage:

-

220V/380V/415V/440V (Customized)

-

Mesh stacking type:

-

automatic robot

Quick Details

-

Wire Diameter (mm):

-

3 - 5 mm

-

Marketing Type:

-

Hot Product 2022

-

Production Capacity:

-

260-320 square meter/hour

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KaiYe

-

Model Number:

-

KY-FRQ-2500

-

Weight (KG):

-

15000

-

Power (kW):

-

5.5

-

HS Code:

-

8515219900

-

welded wire materials:

-

Low carbon steel wire,Galvanized wire, black wire.

-

Line Wire Spacing:

-

50-300 mm

-

Cross Wire Spacing:

-

50-300 mm

-

Fence mesh length:

-

75-2500 mm

-

Fence mesh width:

-

Max. 2500 mm

-

Welding Speed:

-

40-60 Times/min

-

Transformer:

-

150kva*6

-

Voltage:

-

220V/380V/415V/440V (Customized)

-

Mesh stacking type:

-

automatic robot

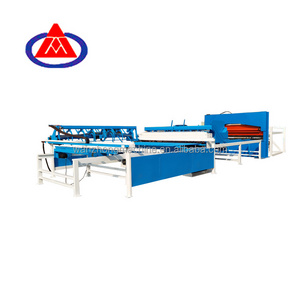

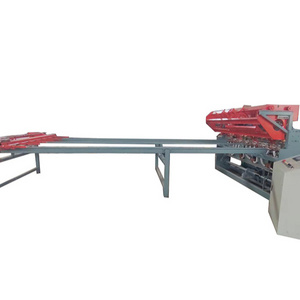

Automatic bending 3D fence panel pneumatic mesh welding machine

(1)Core advantage about our machine:

➀

This machine adopts pneumatic welding system, which can more conveniently adjust the mesh size and change the wire diameter range more simply and flexibly.

➁

This 3D fence mesh welding machine production line is developed and produced by the Chinese technical team and European engineers combined with the use experience of customers. The whole production line is very advanced and each system has been greatly improved.

➂

The line wire feeding system is very precise, and the length range can be 75-2500 mm, the pull mesh system, mesh conveying system and mesh bending system are controlled by different servo motors, it can greatly improve the production speed.

(2)About the bending system

The bending system adopts high-speed bending machine, and the upper and lower molds move at the same time for high-efficiency production. The mesh stacking system adopts intelligent robot stacking system. Its advantage is that it can accurately and quickly place the mesh in order, reduce labor and save cost.

Mechanical advantages:

|

Model

|

KY-FRQ-2500

|

KY-FRQ-3000

|

|

Mesh width

|

Max.2500 mm

|

Max.3000 mm

|

|

Mesh hole size

|

50-300 mm

|

50-300 mm

|

|

Wire diameter

|

3.0-5.0 mm

|

3.0-5.0 mm

|

|

Welding speed

|

40-80 Times/min

|

40-80 Times/min

|

|

Transformer

|

150KVA*6 (water-cooling)

|

150KVA*8 (water-cooling)

|

|

Dimensions

|

12 X 2.5 X 1.85 m

|

12 X 3.0 X 1.85 m

|

|

Weight

|

13500 KG

|

16000 KG

|

Line wire putting trolley system

Line wire pushing system

Line wire positioning system

Cross wire dithering device

Connecting copper block

Electrode and copper base

Welding cylinder

Cylinder switch

Q: How is your factory?

A:

We are factory specializing in the manufacture and export of machines for more than 20 years, all of the production we sale are at a very best price and high quality.

Q: What is your terms of payment?

A:

T/T 30% as deposit, and 70% balance against BL copy.

Q: Warranty and After-sale service?

A:

12 months warranty, man-made destroy will be exception.

B:

After the warranty time, we can supply materials or teach support to you for reducing the cost of you.

Q: Can your company send your engineers to my country for machine installation, worker training?

A:

Yes, our engineers went more than 60 countries before. They are very experienced.

Q: Can you export and supply the customs clearance documents we need?

A:

We have much experience for exporting. And we can supply the CE certificate, Form E, passport etc, your customs clearance will be no problem.

Q: Can you still offer me the best after-sale service?

A:

As we all know, the after-sale service is very important for buying machines, if you have any problem, please feel free to call me and email me.

. Our engineer can also go to your country to help you install and train works for you.

If you have any interest in wire mesh fence panel welding machine or other wire mesh machine products,please feel free to contact with us.

I hope we can provide you with the best machines and services.