- Product Details

- {{item.text}}

Quick Details

-

Size:

-

1220*2440mm

-

Glue:

-

MR,WBP,Melamine

-

Core:

-

recycled plywood,poplar core

-

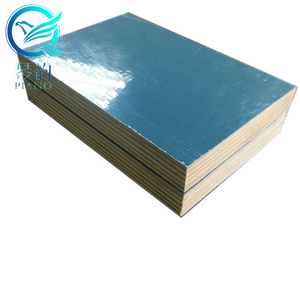

Color:

-

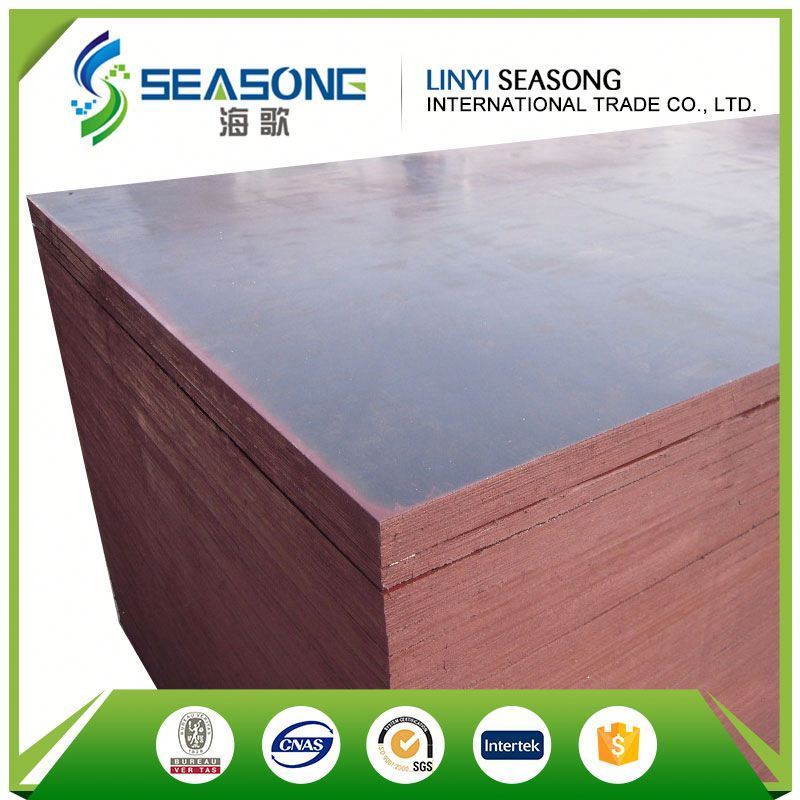

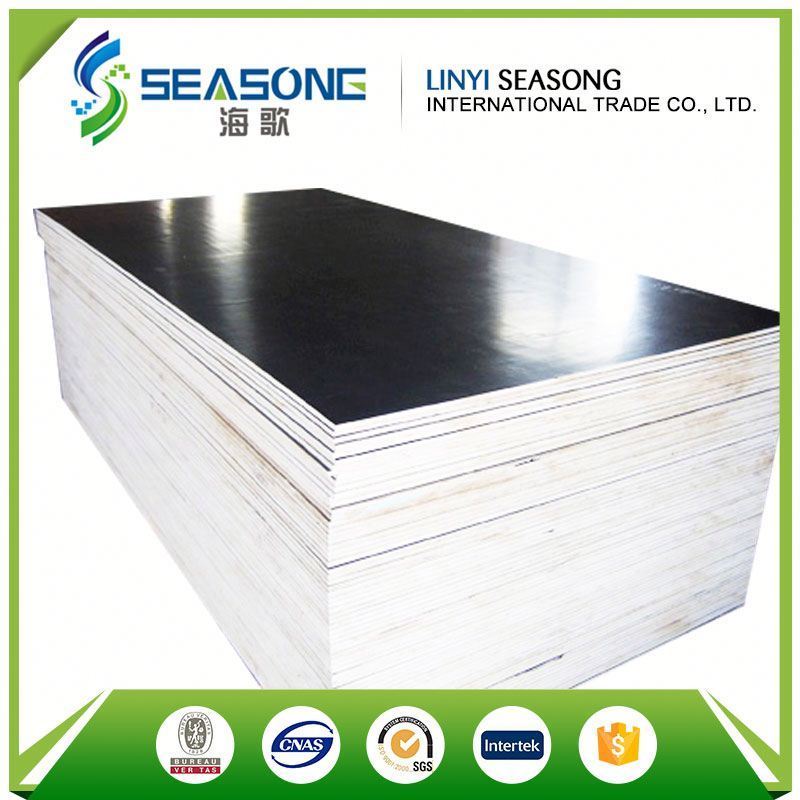

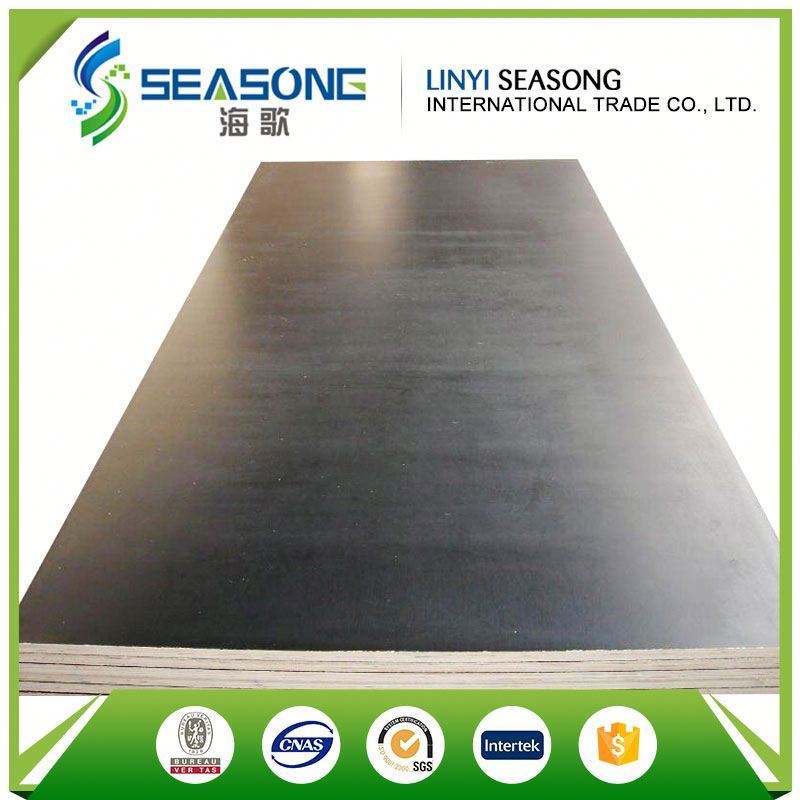

brown, black, red film, or with logo,word faced

-

Thickness:

-

12mm-21mm

-

Density:

-

500-510kg/cbm

-

Hot press:

-

1-2 times

-

Lead time:

-

within 10-15 days after your deposit

-

Certificate:

-

SGS, Intertek,BV

Quick Details

-

Formaldehyde Emission Standards:

-

E2

-

Place of Origin:

-

Shandong, China

-

Product:

-

finger joint film faced plywood

-

Size:

-

1220*2440mm

-

Glue:

-

MR,WBP,Melamine

-

Core:

-

recycled plywood,poplar core

-

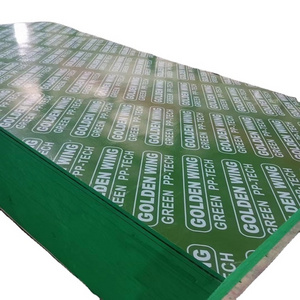

Color:

-

brown, black, red film, or with logo,word faced

-

Thickness:

-

12mm-21mm

-

Density:

-

500-510kg/cbm

-

Hot press:

-

1-2 times

-

Lead time:

-

within 10-15 days after your deposit

-

Certificate:

-

SGS, Intertek,BV

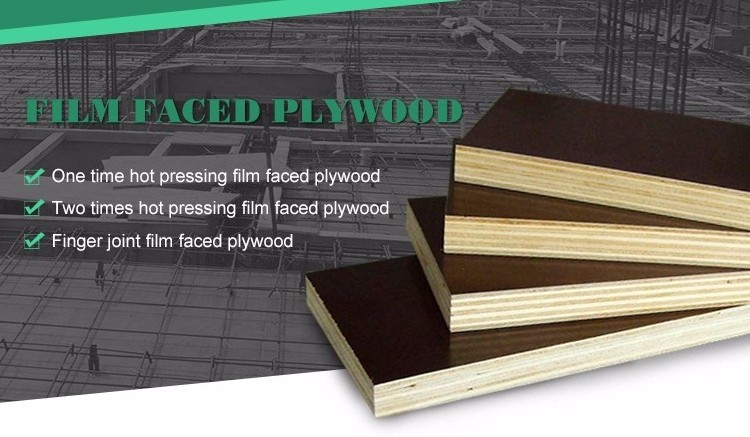

Waterproof PVC Plastic Coated Plywood Sheet for Formwork

The film faced plywood is a kind of temporary model structure to ensure concrete forming,which must bear the horizontal load and vertical load during the construction of concrete structure.Our company produces one time hot pressing film faced plywood,two times hot pressing film faced plywood and finger joint film faced plywood.With the poplar as the basic material,high surface smoothness,has sufficient affordability and stability,light weight,not easy to deformation, can be reused and save production costs.

|

Type |

Film Faced Plywood |

|

Model Number |

4*8 |

|

Grade |

First-Class |

|

Main Material |

Poplar |

|

Formaldehyde Emission Standards |

E1 |

|

Size |

1240*2440mm, 1250*2500mm |

|

Thickness |

9-21mm |

|

Thick tolerance |

± 0.2-0.5mm |

|

Core |

poplar core, hardwood core |

|

Density |

500-550kg/cbm |

|

Film |

brown, black, red film with words or logo |

|

Glue |

MR,WBP Glue(Melamine,Phenolic) |

Light weight : More suitable for constructing in the skyscraper and bridge.

The breadth is big:The biggest breadth is 2500*1250mm,reduces the quantity of seam,improves the efficiency.

1,No warping, no fracture, no out of shape, it can stay 24 hours in boiling water.

2,Good performance and more turnover use time.

3,Make the surface of concrete more smooth and beautiful,So it can be easy to make decoration and it also deduct the processing of plastering.

4,This can moderate and contract 30% time for a project.

5,Corrosion-resistance and it will not pollute the surface of concrete.

6,It is good to keep performance warm,is favorable to make construction in winter.

7,Products can be made into warping plywood.

8,It is better to nail,saw, drill than bamboo and steel mould,and it can be processed into different types.