- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor

-

Design Style:

-

Modern

-

Weight:

-

36kg

-

Chemical Composition:

-

iron

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Cowan

-

Model Number:

-

Steel grating

-

Product name:

-

Channel drain floor grating stainless steel tree grill grates cover

-

Name:

-

steel metal grating

-

Material:

-

Iron

-

Raw material:

-

Low Carbon Steel Q235

-

Surface treatment:

-

Galvanized

-

Usage:

-

Grating

-

Size:

-

Customization

-

Packing:

-

Metal pallet

-

MOQ:

-

28 tons

-

Certificate:

-

ISO:9001:2008

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Outdoor

-

Design Style:

-

Modern

-

Weight:

-

36kg

-

Chemical Composition:

-

iron

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Cowan

-

Model Number:

-

Steel grating

-

Product name:

-

Channel drain floor grating stainless steel tree grill grates cover

-

Name:

-

steel metal grating

-

Material:

-

Iron

-

Raw material:

-

Low Carbon Steel Q235

-

Surface treatment:

-

Galvanized

-

Usage:

-

Grating

-

Size:

-

Customization

-

Packing:

-

Metal pallet

-

MOQ:

-

28 tons

-

Certificate:

-

ISO:9001:2008

Product Description

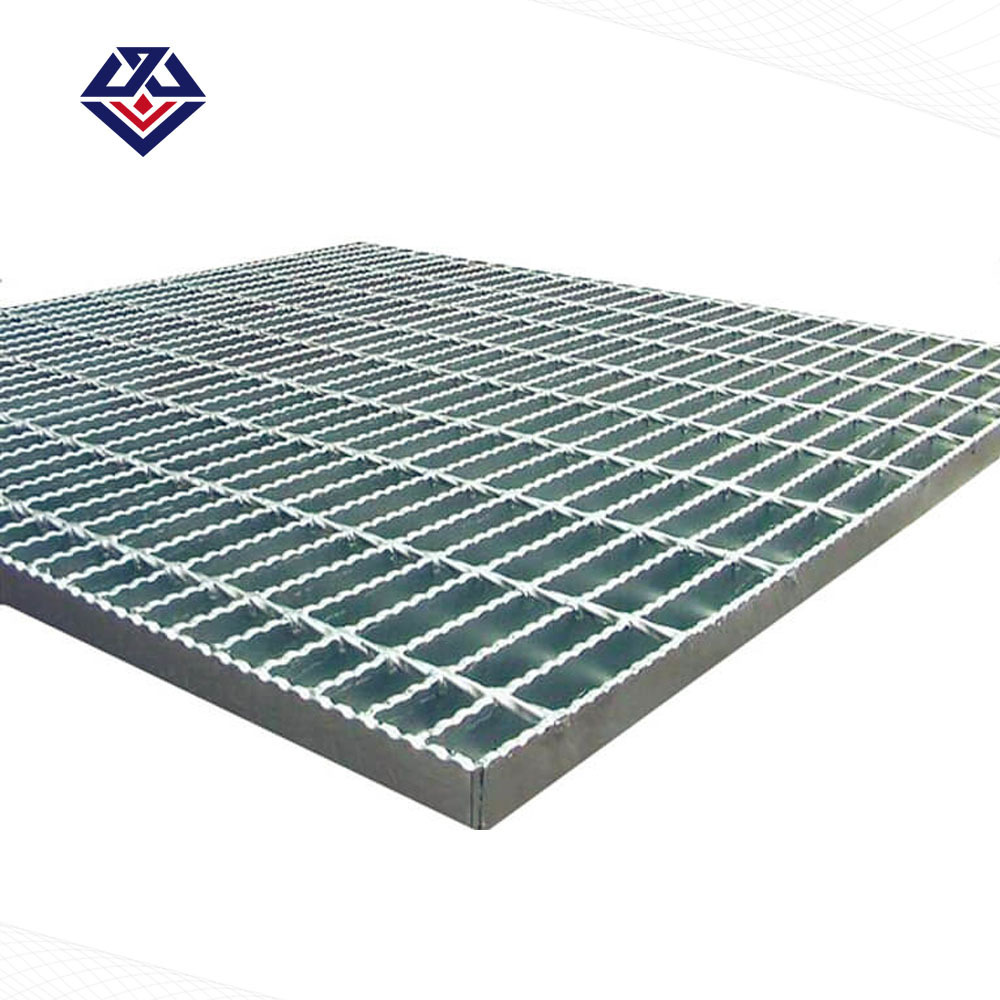

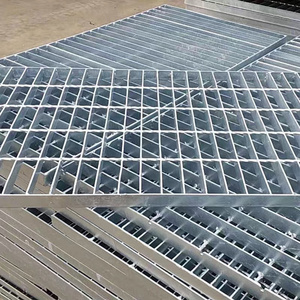

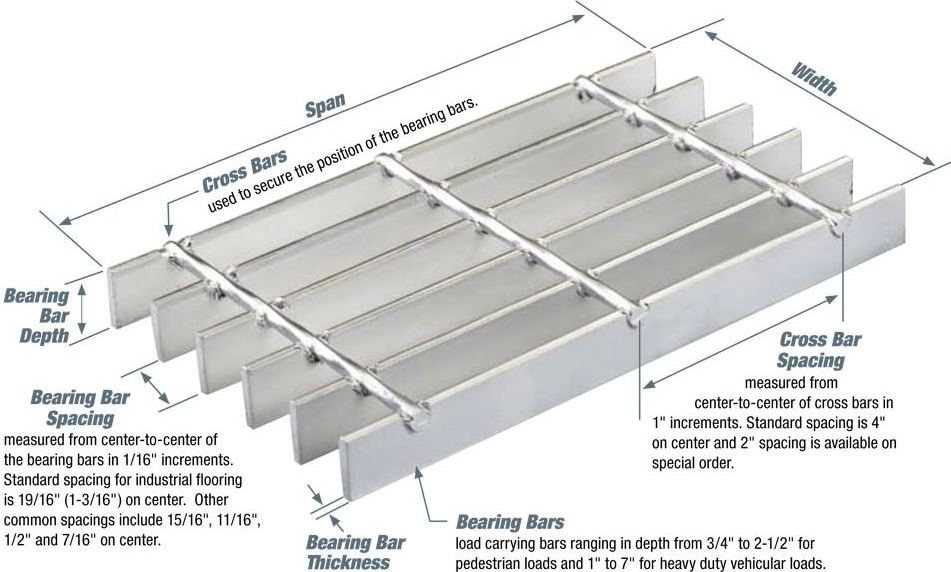

Steel grating

Steel grating typically consists of parallel and perpendicular steel bars, with the perpendicular bars welded or locked into place by various methods such as welding, riveting, or swaging. The design of the grating allows for the passage of air, light, and liquids while providing structural support.

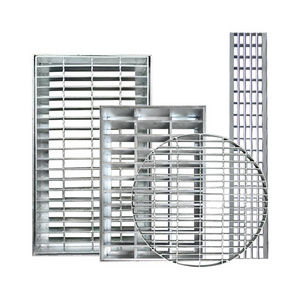

Specification

|

Production name

|

Steel grating

|

|

Material

|

Carbon steel, Stainless steel, Aluminum

|

|

Surface treatment

|

Hot dipped galvanized, Spray-painting, Polished and powder coated

|

|

Bearing Bar type

|

Flat bar, Serrated bar, I-bar, inserting steel grating etc

|

|

Beaing bar size

|

20*3mm, 25*3mm, 30*3mm, 32*3mm, 40*3mm, 50*3mm, 60*3mm, 70*3mm

20*4mm, 25*4mm, 30*4mm, 32*4mm, 40*4mm, 50*4mm, 60*4mm, 70*4mm

20*5mm, 25*5mm, 30*5mm, 32*5mm, 40*5mm, 50*5mm, 60*5mm, 70*5mm

|

|

Mesh size

|

30*100mm, 40*100mm, 50*100mm,

30*50mm, 40*50mm, 50*50mm,

30*30mm, 34*38mm

|

|

Use to

|

flooring, catwalk, decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, workshops, motor rooms, trolley channels, heavy loading areas, boiler equipment and heavy equipment areas, etc.

|

Customization product

Support customization of various sizes, customization requires data:

1.Bearing bar depth

2.Bearing bar thickness

3.Bearing bar pitch

4.Cross bar pitch

5.Span and Width (mesh size)

For more product dimensions, please refer to the detailed page below.

2.Bearing bar thickness

3.Bearing bar pitch

4.Cross bar pitch

5.Span and Width (mesh size)

For more product dimensions, please refer to the detailed page below.

Production line

1. Material Preparation

The process begins with the preparation of raw materials. This involves sourcing high-quality steel bars, usually made of carbon steel or stainless steel, in the required dimensions and specifications.

2. Cutting

The steel bars are cut to the desired length using cutting machines or shears. Precision cutting ensures that the bars are uniform in size and ready for the next step.

3. Welding

The cut steel bars are then assembled into panels by welding. This involves positioning the bearing bars and crossbars at predetermined intervals and welding them together at their intersections.

4. Finished black panel

Welded the size as customers requirement.

Ensure a secure and durable connection.

5. Surface Treatment

The steel grating panels may undergo surface treatment processes such as galvanization to enhance corrosion resistance and prolong

the lifespan of the grating.

the lifespan of the grating.

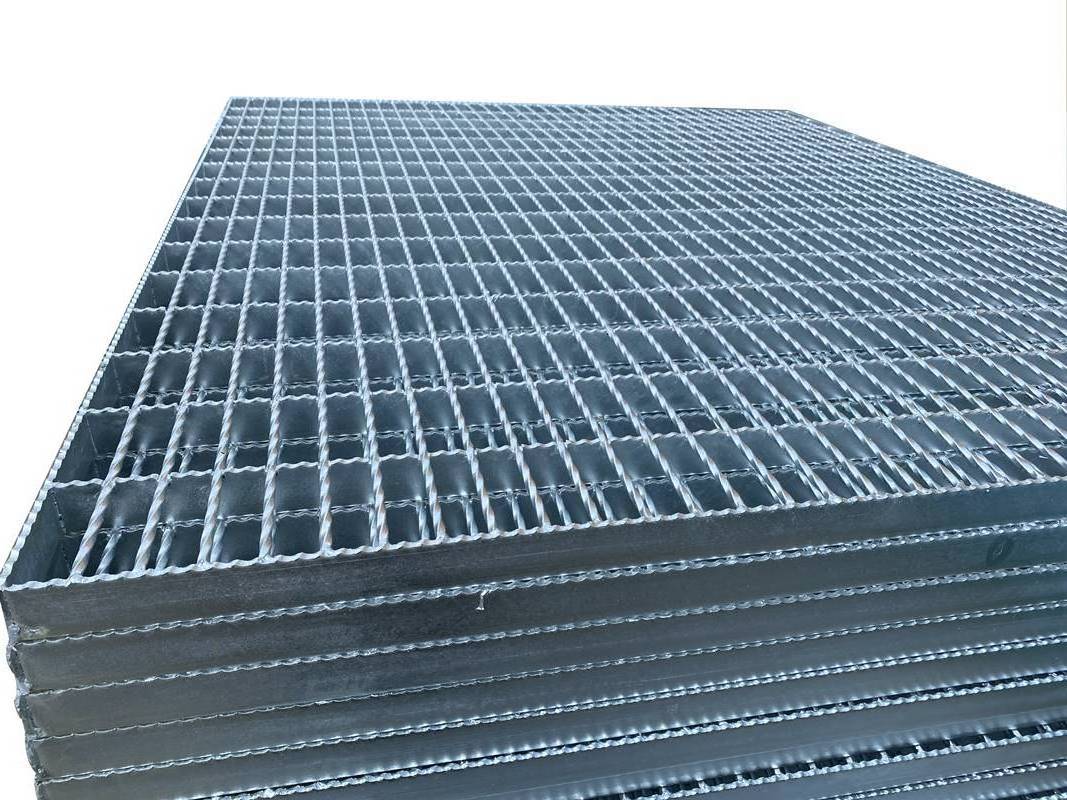

6. Packaging

Packaged securely for transportation to customers or storage. Proper packaging helps prevent damage during transit and ensures

that the grating panels arrive in good condition.

that the grating panels arrive in good condition.

Products Details

Hot Searches