- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Maydos

-

Model Number:

-

JD2000

-

Service life:

-

Over 8 years

-

Surface dry:

-

15-30 minutes

-

Hard Dry:

-

6 Hours

-

Recoat Time:

-

3-4 hours

-

Color:

-

Various option

-

Theoretical coverage:

-

10-15 square meter

-

Keywords:

-

Epoxy Floor Finish

-

Substrate:

-

Cement Floor

-

Feature:

-

Anti-static

Quick Details

-

CAS No.:

-

3209909000

-

Other Names:

-

Epoxy Floor Paint

-

MF:

-

Mixture

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Maydos

-

Model Number:

-

JD2000

-

Service life:

-

Over 8 years

-

Surface dry:

-

15-30 minutes

-

Hard Dry:

-

6 Hours

-

Recoat Time:

-

3-4 hours

-

Color:

-

Various option

-

Theoretical coverage:

-

10-15 square meter

-

Keywords:

-

Epoxy Floor Finish

-

Substrate:

-

Cement Floor

-

Feature:

-

Anti-static

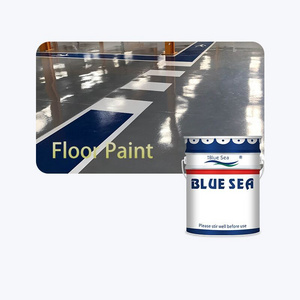

Maydos Self Leveling Epoxy Floor Paint

Description:

Maydos JD-2000 is a kind of two-pack self leveling weathering&corrosion resistant floor paint. It owns such features as weathering resistance, corrosion and yellowing resistance which make it suitable for indoor or outdoor use. It can combine with the concrete substrate tightly. Low shrinkage, wearable and durable. JD-D10 is a two-component solvent epoxy primer. It has good penetration and sealing power on the porous substrate, such as concrete and water whetstone, etc. It can reinforce the substrate strength and provide good adhesion. It is also an all-purpose primer for epoxy series paints and used as the undercoat or putty coat after used together with quartz sand or quartz powder.

Advantages:

1. Beautiful, seamless, dustproof and easy to clean.

2. Strong adhesion, small shrinkage

3. Corrosion-resistance to the general chemicals.

4. Good abrasion resistance and durability.

Configuration of Coating System:

Requirements for the base:

1. Concrete strength≥C25;

2. Flatness: the maximum altitude difference of 2M running rule<3mm.

3. The moisture content of the base<4%

Technical Data:

Drying time:

Touch dry: 4 hours

Hard dry: 2-4 days

Compressive strength (Mpa): 80

Impact resistance strength (Kg·cm): 40

Flexural strength (Mpa): 40

Adhesive force grade: 1

Pencil hardness (H): 3

Abrasion resistance(750g/1000r, zero gravity, g)≤0.03

Service life: 8-10 years

Recommended Consumption:

Primer: 0.15kg/sqm

Undercoat: 0.3kg/sqm

Putty layer: 0.2kg/sqm

Quartz Sand: 0.45kg/square meter

Quartz Powder: 0.2kg/square meter

Top coat: 0.8kg/sqm

Application instructions:

1. Surface preparation:Correct substrate preparation is critical for optimum performance. Surface

should be sound, clean, dry and free from loose particles, oil, grease, and other contaminants.

2. Primer: Mix JD-D10 A and JD-D10B in a barrel according to 1:1 by weight. The reference

consumption is 0.15kg/sqm.The main purpose of this primer is to seal the substrate completely and

avoid air-bubbles in the body coat. According to the oil absorption condition of substrate, a second

coat may be required. The paint should be stirred evenly, then apply directly with roller. Wait for 8

hours to recoat.

Inspection standard for the primer: even film with certain brightness.

3. Undercoat: Prepare a barrel, mix JD-D10A and JD-D10B according to 1:1 in it, pour in appropriate

quartz sand, stir completely and then apply the mixture with trowel. Wait for about 8 hours, sand

the coat with grinding machine, clean the dust and then continue the next process.

Inspection standard for the undercoat: Non-sticky to hand, no softening, no nail print if you

scratch the surface.

4. Putty layer: Prepare a barrel, mix JD-D10A and JD-D10B in it according to 1:1, pour in appropriate

quartz powder, stir completely and then apply the mixture directly with trowel. Wait for 12 hours,

sand the coat with grinding machine, clean the dust and continue the next process.

Inspection standard for the putty layer: Non-sticky to hand, no softening, no nail print if you

scratch the surface.

5. Top coat: Mix JD-2000A and JD-2000B according to 5:1 and then apply the mixture with scraper

.

6. Overcoat varnish: Apply this varnish over the top coat with roller. The consumption quantity is

0.1kg/sqm. One coat will be enough.

7. Maintenance: 5-7 days. Don’t use or wash with water or other chemicals.

Clean up

Clean tools and equipments first with paper towels, then clean the tools with solvent before the paint

hardens

Health and safety information

It contains certain chemicals which can cause skin irritation. Wear gloves, masks while handling the

product, washing thoroughly after handling. Should skin contact occur, wash immediately with soap

and water.

During application and curing in closed rooms, adequate fresh air ventilation must be provided. Keep

away from open flames including welding.

In case of accidental eye contact, wash with a large quantity of water and immediately seek medical

advice.

For detailed health, safety, environment recommendations, please consult and follow the instruction

on the product material safety data sheet.

Disclaimer

The information given in this sheet is not intended to be exhaustive. Any person using the product

without first making further written enquiries as to the suitability for the intended purpose does so at

his own risk and we can accept no liability of the product for any loss or damage arising out of such

use. Product data are subject to change without notice and become void five years from the date of

issue.

Note

The above information is given to the best of our knowledge based on laboratory tests and practical

experience. However, since we cannot anticipate or control many conditions under which our products

may be used, we can only guarantee the quality of the product itself.

We reserve the right to alter the given information without prior notice.

5L(6.5KG), 2 tins in 1 carton, 1620 tins for one 20FT container

18L(22KG), no carton package, 1078 tins for one 20FT container

20L(24KG), no carton package, 924 tins for one 20FT container